This information is aimed for filtering vegetable oil and biodiesel but is essentially universal for any liquid filtering. Filtering can be done using strainers, filter bags, settling techniques and in the poor man method aka: using old clothing (not recommended as it makes a mess and requires a LOT of old clothes.)

An indirect way to determine if moisture levels are in balance with vacuum and temperature is to monitor the moisture content of the oil coming out of the bleaching filter. The process is deemed optimal when the moisture content of the oil leaving the filter press approaches 0.05 weight % from the high side of the optimal range. Filtration

Get Price

Setting up and running a small-scale cooking oil business - 6 - About the authors Barrie Axtell is a British food technologist with over 30 yearsexperience working in Africa, Caribbean, Asia and Latin America. His particular interest centres on small-enterprise-based drying of fruits and vegetables and

Get Price

Forth Step of Vegetable Oil Refining Process. Deodorization Process is the forth step in vegetable oil refining which commences after finishing the bleaching. Deodorization holds a big impact on the refined oil quality and is often considered as the heart of the entire edible oil refining method.

Get Price

Processing Edible Oils; Processing Edible Oils in the oil can be harmful to a diesel engine and is one of the compounds with a maximum limit set in the standard for vegetable oil for use as engine fuel. Shown on the left is a sample that is mixed with the oil, heated, and put through a filter press. On the right is a sample that is used

Get Price

Dewaxing process is mainly done in sunflower oil in crystallizers to remove the wax content from the crude vegetable oils. The final edible oil is free from waxes. Special transfer pump will slowly feed the slurry to the Filter press. Filtration yields clear liquid oil and the by-product waxes as output.

Get Price

Chapter 5 : Processing and refining edible oils. Contents - Previous - Next. Rural vegetable oil production Large-scale production Industry can design almost any fat or oil for a specific application by the use of various modification processes, such as hydrogenation, interesterification, fractionation or blending.

Get Price

Design and Development of a Bench Scale Vegetable Oil Based Fuel Processing Tecnology (2015) Prakash Bhoi, Raymond Huhnke, Ajay Kumar, Krushna N. Patil, et al.

Get Price

Related Filter Press - Oil Extraction - Vegetable Oil Company Introduction Our experience, based on the investigation and development of projects related to biofuels, allows us to offer a complete service that starts with a general feasibility study of the project and finishes with the start up of the plant.

Get Price

This project work represents the design and construction of an oil expeller press, performance test of it with several raw materials e.g. coconut, rape seed, sesame, sunflower seed and structural

Get Price

Soybean oil is a vegetable oil that is extracted from the seeds of the soybeans. Soybean oil is one of the most widely consumed cooking oils across the world. Apart from that, it can also be used as a base for printing inks and oil paints. In order to process soybean oils from soya beans, soybean oil pressing line is necessary.

Get Price

This oil can be labeled ll naturalin good conscience, due to the absence of solvents and/or harsh chemicals. Conclusions. Physical refining of vegetable oils offers great opportunity for green vegetable oil processing, and is a contribution toward sustainability of oil mills and refineries, as supported by the following.

Get Price

Chapter 5 : Processing and refining edible oils. Contents - Previous - Next. Rural vegetable oil production Large-scale production Industry can design almost any fat or oil for a specific application by the use of various modification processes, such as hydrogenation, interesterification, fractionation or blending.

Get Price

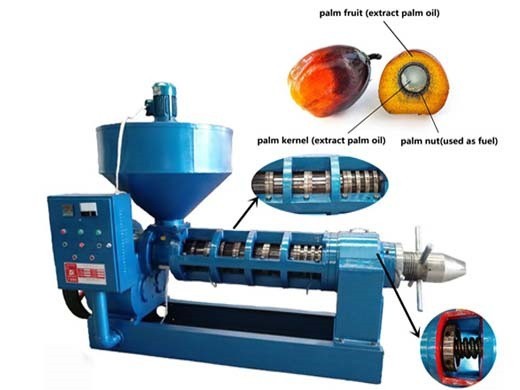

Commercial oil press machine is mainly used to produce edible oils for business purposes. It is great choice for mobile oil factory, mini oil pressing workshp and various oil mill plants. Compared to oil machine, commercial oil press machine is efficient in oil extraction and larger in size.

Get Price

Classical chemical refining is used to make the oil suitable for human consumption, through successive steps: it must be degummmed, neutralised, bleached, deodorised and sometimes winterized. Neutralisation can also be done by distillative removal of the free fatty acids in the deodorizer. The latter sequence is better known as physical refining.

Get Price

Related Filter Press - Oil Extraction - Vegetable Oil Company Introduction Our experience, based on the investigation and development of projects related to biofuels, allows us to offer a complete service that starts with a general feasibility study of the project and finishes with the start up of the plant.

Get Price

The oil press is characterized by its sophisticated design which is easy to operate. Gemco owns several national patents for its oil press technology. The quality of Gemco oil press system is of above the China national standard, and is CE certified. Our oil press and filter press for vegetable oil and biodiesel are CE certified.

Get Price

Soybean oil is a vegetable oil that is extracted from the seeds of the soybeans. Soybean oil is one of the most widely consumed cooking oils across the world. Apart from that, it can also be used as a base for printing inks and oil paints. In order to process soybean oils from soya beans, soybean oil pressing line is necessary.

Get Price

Since vegetable oil prices in the United States are held artificially high by farm subsidies, unused vegetable oil has only recently become comparable in price to petro-diesel. In 1999, diesel was close to a dollar per gallon; fresh vegetable oil was almost three times as expensive, making it a hard sell as an alternative fuel.

Get Price

6. Challenges of Biodiesel Industry Development Increased demand for vegetable oil as an biodiesel feedstock is altering world agricultural landscapes and the ecosystem services they provide, which will highlight a number of negative effects associated with its use.

Get Price

Processing Edible Oils; Processing Edible Oils in the oil can be harmful to a diesel engine and is one of the compounds with a maximum limit set in the standard for vegetable oil for use as engine fuel. Shown on the left is a sample that is mixed with the oil, heated, and put through a filter press. On the right is a sample that is used

Get Price

Classical chemical refining is used to make the oil suitable for human consumption, through successive steps: it must be degummmed, neutralised, bleached, deodorised and sometimes winterized. Neutralisation can also be done by distillative removal of the free fatty acids in the deodorizer. The latter sequence is better known as physical refining.

Get Price

Oil palm is now the most important supplier of vegetable oil in the world. Machinery can offer you the BEST customized palm oil processing solutions for both fresh fruit bunch and palm kernel/nut. With years of experience in oil extraction and refinery filed, we are capable of turnkey oil mill plant construction, including process

Get Price

Processing Edible Oils; Processing Edible Oils in the oil can be harmful to a diesel engine and is one of the compounds with a maximum limit set in the standard for vegetable oil for use as engine fuel. Shown on the left is a sample that is mixed with the oil, heated, and put through a filter press. On the right is a sample that is used

Get Price

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines - biochemistry, chemical and mechanical engineering - and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

Get Price

Vegetable oils are an interesting alternative to diesel fuel, as they are a renewable source of energy, have a low sulfur content, are safe to store, do not cause skin ailment. However, using vegetable oils in order to fuel direct injection diesel engines creates problems due to their low heat energ

Get Price

Since vegetable oil prices in the United States are held artificially high by farm subsidies, unused vegetable oil has only recently become comparable in price to petro-diesel. In 1999, diesel was close to a dollar per gallon; fresh vegetable oil was almost three times as expensive, making it a hard sell as an alternative fuel.

Get Price

6. Challenges of Biodiesel Industry Development Increased demand for vegetable oil as an biodiesel feedstock is altering world agricultural landscapes and the ecosystem services they provide, which will highlight a number of negative effects associated with its use.

Get Price

Contact to Goyum Screw Press Ludhiana India.We are Manufacturer of Vegetable Oil Seed Oil Extraction Machine, Mustard Seed Oil Extraction Machine by Goyum Screw Press, View Mobile No, Email, Phone no and Website.

Get Price

Oil palm is now the most important supplier of vegetable oil in the world. Machinery can offer you the BEST customized palm oil processing solutions for both fresh fruit bunch and palm kernel/nut. With years of experience in oil extraction and refinery filed, we are capable of turnkey oil mill plant construction, including process

Get Price

Classical chemical refining is used to make the oil suitable for human consumption, through successive steps: it must be degummmed, neutralised, bleached, deodorised and sometimes winterized. Neutralisation can also be done by distillative removal of the free fatty acids in the deodorizer. The latter sequence is better known as physical refining.

Get Price

The oil press is characterized by its sophisticated design which is easy to operate. Gemco owns several national patents for its oil press technology. The quality of Gemco oil press system is of above the China national standard, and is CE certified. Our oil press and filter press for vegetable oil and biodiesel are CE certified.

Get Price

MSME-Development Institute, Ministry of MSME, Government of India 107, Industrial Estate, Kalpi Road, Mustard Oil is also one of the major oil seeds from which edible oil is produced. In Northern & Central India, it is medium of Filter press frame type 14X 14X 14plates plunger pump and filler cloth. 1 No. 55,000/- 0.55

Get Price

Since vegetable oil prices in the United States are held artificially high by farm subsidies, unused vegetable oil has only recently become comparable in price to petro-diesel. In 1999, diesel was close to a dollar per gallon; fresh vegetable oil was almost three times as expensive, making it a hard sell as an alternative fuel.

Get Price

Vegetable oil solvent extraction plant for sale_vegetable oilThe solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean fter flaking or it extracts oils from prepressed or fully pressed cake

Get Price

The Desmet Ballestra Group is the world leader in developing, engineering and supplying technologies, processing plants and proprietary equipment for the following business areas: Oils & Fats, Rosedowns Pressing, Stolz Animal Feed & Agro Food, Oleochemicals & Biodiesel, Detergents, Surfactants & Chemicals, Mazzoni LB Soap.

Get Price

Oil palm is now the most important supplier of vegetable oil in the world. Machinery can offer you the BEST customized palm oil processing solutions for both fresh fruit bunch and palm kernel/nut. With years of experience in oil extraction and refinery filed, we are capable of turnkey oil mill plant construction, including process

Get Price

Oil Expeller an Important Component of Oil Extraction Plant. Oil expeller, also known as screw oil press machine and it the heartbeat and most important oilseeds extraction machine in the whole vegetable oil extraction plant. Goyum Oil Expeller is suitable for small scale, medium and large scale oil extraction plant.

Get Price

Classical chemical refining is used to make the oil suitable for human consumption, through successive steps: it must be degummmed, neutralised, bleached, deodorised and sometimes winterized. Neutralisation can also be done by distillative removal of the free fatty acids in the deodorizer. The latter sequence is better known as physical refining.

Get Price