Economic Impact Analysis for the Proposed Vegetable Oil Processing NESHAP U.S. Environmental Protection Agency Office of Air Quality Planning and Standards

Vegetable oils, or vegetable fats, are oils extracted from seeds, or less often, from other parts of fruits. Like animal fats, vegetable fats are mixtures of triglycerides. Soybean oil, rapeseed oil, and cocoa butter are examples of fats from seeds. Olive oil, palm oil, and rice bran oil are examples of fats from other parts of fruits. In common usage, vegetable oil may refer exclusively to ...

Get Price

Expanding the Use of Physical Refining to Other Oils. For brevity, all the processes above are related to soybean oil. It should be emphasized that the processes are equally good for all vegetable oils, such as sunflower oil, canola oil, cottonseed oil, peanut oil, safflower oil, etc. The processes are applicable for all the high FFA vegetable ...

Get Price

Vegetable oils are the basis of biodiesel, which can be used like conventional diesel. Some vegetable oil blends are used in unmodified vehicles, but straight vegetable oil needs specially prepared vehicles which have a method of heating the oil to reduce its viscosity and surface tension. Another alternative is vegetable oil refining.

Get Price

Vegetable Oil Refining - Crude oil is typically shipped for refining to establishments engaged in the production of edible vegetable oils, shortening, and margarine. Crude vegetable oils contain small amounts of naturally occurring materials such as proteinaceous material, free fatty acids, and phosphatides. Phosphatides

Get Price

Refining of edible oils: A critical appraisal of current and potential technologies Article (PDF Available) in International Journal of Food Science & Technology 50(1) · September 2014 with ...

Get Price

Oil Deodorization Section of the Oil Refining Plant. As the name suggests this process is meant for the removal of odor. Every vegetable oil has its own distinct natural odor. During neutralization and bleaching, unpleasant odors are imparted in the oil, thereby making it essential to remove this odor.

Get Price

Vegetable Oil Refining Vegetable Oils Refining is necessary for vegetable oils & fats or animal oils & fats so they can be used for cooking and frying foods. Chemically speaking, oils are Tri-Glycerides or “Fatty-Acid Glycerin Esters” (FAGE). One Glycerin molecule combines with three Fatty-Acid molecules to form one FAGE. Oils are a blend ...

Get Price

Edible Oil Refining is a general term for the removal of solid impurities, free fatty acids, phospholipid, colloid, wax, pigment and odors in vegetable oils. The presence of impurities contained in crude oils not only affects the use value, the safety storage of crude oil, but also cause difficulties for the deep processing crude oils.

Get Price

Vegetable oils are also used to make biodiesel, which can be used like conventional diesel. Some vegetable oil blends are used in unmodified vehicles but straight vegetable oil, also known as pure plant oil, needs specially prepared vehicles which have a method of heating the oil

Get Price

The transition can start with biodiesel, vegetable oil refining, and vegetable oil blends, since these technologies do not require the capital outlay of converting an engine to run on vegetable oils. Because it costs to convert vegetable oil into biodiesel it is expected that vegetable oil

Get Price

The oil normally becomes cloudy in 5–6h but with proper dewaxing the oil remains clear after 24h of storage at 0˚C. The following steps are used to dewax sunflower oil: Crude oil is refined and bleached to low phosphorus (<1ppm) and low moisture content (<0.1%). The oil is heated to 55˚C to make sure the oil

Get Price

vegetable oil industry, producing about 75 percent of the domestic supply of vegetable oil. Vegetable oils are used almost entirely for human consumption, although small quantities are used for industrial

Get Price

- lower refining costs. Nevertheless, it must be emphasized that not all types of oil can be satisfactorily refined by physical system. Generally speaking, physical refining is successful with some specific oils, typically PALM OIL, OLIVE OIL and LAURIC OILS while, on other oils, it can be successful only provided that a very REFINING

Get Price

Vegetable Oil Refining Vegetable Oils Refining is necessary for vegetable oils & fats or animal oils & fats so they can be used for cooking and frying foods. Chemically speaking, oils are Tri-Glycerides or

Get Price

Rural refining of oil-bearing plants can produce fats and oils of good quality which provide needed energy and fat soluble vitamins. Commercial refining produces fats and oils that can be of high

Get Price

In 1995, the baseline year of the analysis, the affected producers are the 106 vegetable oil processing facilities that produce vegetable oil and meal using a solvent extraction process. Both new and existing producers will be affected. A total of 31 companies are identified as owners of these vegetable oil

Get Price

Edible/vegetable oil refining is a step by step process. Refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. The entire oil refining

Get Price

Oil Deodorization Section of the Oil Refining Plant. As the name suggests this process is meant for the removal of odor. Every vegetable oil has its own distinct natural odor. During neutralization and bleaching, unpleasant odors are imparted in the oil

Get Price

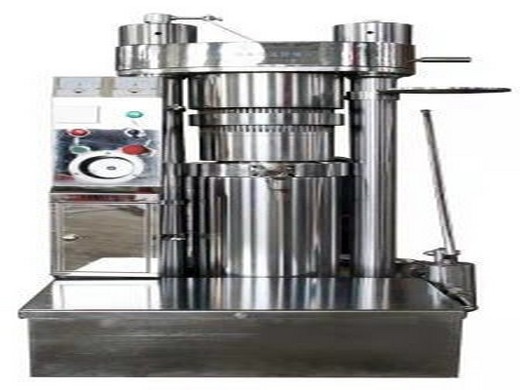

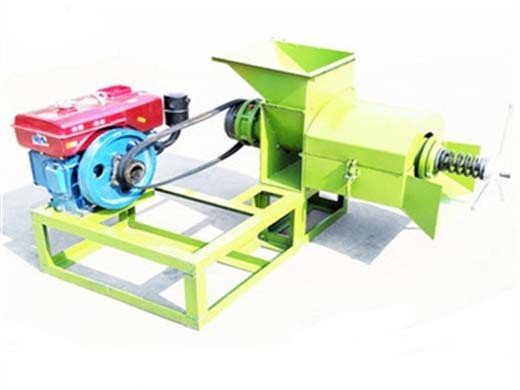

The batch edible oil refinery plant can be used to produce 1 st and 2 nd grade oil from crude vegetable oil. It also can process animal oil, such as fish oil, pig oil, duck oil and so on. The suitable capacity is 1-30T per day. However, different oils have different processes.

Get Price

The purpose of vegetable oil refining is to remove undesirable impurities that affect quality (taste, smell, appearance) and the shelf life of refined oils. Due to the wide variety of these impurities—free fatty acids, metal ions, color compounds, smells, gums, etc.—a series of processes of chemical and physical nature must be employed for the refining.

Get Price

In fact, as a responsible supplier of edible oil refining machine, we are explicit that the EXACT cost of the edible oil refinery machine is decided by various aspects, including capacity, oil property, requirement for final produced oil, local market, etc. The Edible Oil Refining Plant Cost in small scale level ranges $21,000~$115,000.

Get Price

Vegetable Oil Refining Mahine in the Oil Factory. If you are planning to build a small edible oil production line, contact us now to get a customized project plan for FREE! All our equipment are sold directly from our oil press factory to eusure all our clients can enjoy the best price! Vegetable Oil Production Plant Setup Cost

Get Price

Process Description of Vegetable Oil Refining is as follows. Water Degumming : Water Degumming is first step in the Edible Oil Refinery Process.Oils contains Hydratable Phosphatide which absorb the water, that Hydratable Phosphatides are oil- insoluble which easily separated by centrifuge.

Get Price

9-7-2014· Oil refining processes for vegetable oils are designed to remove these impurities from the oil or reduce them to a level where their deleterious effects on oil stability are minimum and made suitable for human consumption. Vegetable oil undergoes degradation almost

Get Price

The purpose of refining edible oils and fats is to remove free fatty acids and other objectionable substances including impurities while maintaining the nutritional value and ensuring the quality and stability of the end product. FEDIOL has developed a Code of Practice for refining vegetable oils (link), on which the description below is based.This process consistently yields safe products.

Get Price

Edible Oil Refinery Plant Manufacturers & Exporters. Muez-Hest is a technology development and EPC with a large part of our expertise pertaining to Edible Oil Refinery Plant Manufacturers & Exporters. Edible Oil Refinery Plant requires precision of machinery while ensuring minimum addition of contaminants and odour producing agents.

Get Price

Edible Oil Refining Machine And Refined Bleached Deodorized. The refined oil reaches the edible oil standard while finished refining process. Oil refining line Application: Our refining machine is suitable for refining various of crude oil, vegetable oil, such as palm kernel oil, sunflower seed oil, tea seed oil, peanut oil, soybean oil, corn oil, groundnut oil, rapeseed oil and so on.

Get Price

Table 2. Refining targets for various minor components in edible oils: Minor component: Refining target (concentration in fully refined oil) trans Fatty acids <1.5% for oils rich in linolenic acid (soybean oil, rapeseed oil, canola, etc.) <1.0% for other vegetable oils (corn oil, sunflower oil, etc.) Tocopherols

Get Price

Oil refinery plant refers to a series of refining processes that can remove phospholipids, FFA, pigment, off-flavor and other impurities in the oil.Edible oil refinery or vegetable oil refinery is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (F. F.A.) from the oil

Get Price

We offer 320 edible oil refining plant cost products. A wide variety of edible oil refining plant cost options are available to you,

Get Price

Crude oil contains impurities of phosphatides, waxes, pigments & FFA which are harmful to our health. 1~10T/D oil refining production line is essential to remove impurities, improve oil flavor & quality and extend shelf life and it’s suitable for the small oil refining business owner.

Get Price

Vegetable Oil Processing Plant Cost, Market Trends Published on May 18, 2015 A new study on the Global Vegetable Oil Industry has been released by IMARC Group.

Get Price

Vegetable oil refining. Six vegetable oils and fats refineries in the port of Rotterdam make the port a major player in the supply of edible oils to the European food industry. In Rotterdam, oils such as palm oil, sunflower oil, rapeseed oil and coconut oil are

Get Price

The by-products acid oil from soapstock of vegetable oil refining and olive pomace oil were evaluated for biodiesel production. Enzymatic hydroesterification was studied to convert the acid oil ( ̴ 34 wt.% free fatty acids) into methyl esters; due to the low free fatty acid content of the fresh olive pomace oil ( ̴ 2 wt.%), alkaline transesterification was conducted. The results from the

Get Price

BASICS OIL REFINING Gerrit van Duijn gerritvanduijn consultancy MVO course, June 2016 1. 2 Agenda Oils and fats sources Supply chains Refining or purification List the 5 most important global vegetable oils and rank them according annual production volume. Edible oils Oil content World production % million ton/annum Seed oils Soybean 18 48

Get Price

We offer 106 low cost vegetable oil refinery equipment products. About 100% of these are Oil Pressers. A wide variety of low cost vegetable oil refinery equipment options are available to you,

Get Price

I sense you are trying to determine how much the markup on a the resulting gasoline product is at the pump. Well, it is a lot more complex than simple cost of refining. First you have lifting costs. Lifting costs are how much it costs you to get a...

Get Price

According to the latest report, the global vegetable oil market has grown at a CAGR of 3.6% during 2014-2025 with consumption volumes reaching 207.5 Million Tons in 2025.

Get Price