Edible oil refining is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils. These impurities include Moisture, Solids, Gums, Free-Fatty Acids (FFA), Waxes, and Compounds of Sodium, Potassium, Magnesium, Calcium, and other metals.

Functions of Oil Refining Plant Oil refining process can remove the different kinds of impurity in the Crude Edible Oil. Oil refining process can improve the oil quality. Such as the taste, the smell, the colour, the acid value, etc. which affects human consumption. After oil refining, the cooking

Get Price

Edible Oil Refining Process 1.Distilling, which heats the oil to evaporate off chemical solvents from the extraction process. 2.Degumming, by passing hot water through the oil to precipitate out gums and proteins... 3.Neutralization, or deacidification, which treats the oil with sodium hydroxide

Get Price

Edible oil refinery plant and edible oil refining process Edible oil refining technology used in edible oil refinery plant is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils.

Get Price

Mini Oil Refinery Plant Mini Oil Refining Plant Working Process Degumming: the process to remove gelatinous impurities within crude oils by chemical or physical methods is called degumming. In edible oil, if the content of phosphatide is high, it is easy to blister, smoke and smell when heated.

Get Price

Next step in Edible Oil Refinery is the Deodorization Plant. We are leading manufacturer of oil Deodorization Plant which is best for Soybean Oil Refining, Sunflower Oil Refining, Cottonseed Oil Refining, Rice Bran Oil Refining, Mustard Oil Refining etc.

Get Price

Edible Oil Refinery Plant. GOYUM provides complete solution for Batch & Continuous type Edible Oil Refinery Plant, capacity to design, build and supply Plants from 5 tonne to 500 tonnes per day.

Get Price

Edible Oil Refinery Plants and Edible Oil Refining are of vital consideration when it comes to Edible Oil Technology. We manufacture and export cost effective Mini Oil Refinery Plants along with customized solutions for Cooking Oil Refinery.

Get Price

The crude oil obtained from oil mill plants and solvent plants get refined in the oil refinery plants before it is utilized directly. The oil through the oil refining process gives color uniformity and appealing quality to the oil by removing unpleasant smell and undesirable factors from the oil.

Get Price

Bleaching is the term given to describe the adsorptive cleansing process associated with edible oil refining. This process may involve acid pretreatment, introduction of and a retention period with a bleaching agent and removal of the clay and absorbed materials.

Get Price

KMEC is a leading designer, manufacturer and exporter of the edible oil refining plants in both continuous type units and batch type units.Our high-tech refinery plant finds an extensive application for all types of crude oil like cotton seed, soyabean, sunflower, palm oil, rice bran oil etc. Edible Oil Refining Process

Get Price

Oil Deodorization Section of the Oil Refining Plant. As the name suggests this process is meant for the removal of odor. Every vegetable oil has its own distinct natural odor. During neutralization and bleaching, unpleasant odors are imparted in the oil, thereby making it essential to remove this odor.

Get Price

The main aim of edible oil refining is to make the oil suitable for human consumption and DVC provide solutions of sunflower, vegetable oil refining plant. The main aim of edible oil refining is to make the oil suitable for human consumption and DVC provide solutions of sunflower, vegetable oil refining plant

Get Price

Process Description of Edible Oil Refinery Plant. As per the today market research it is being concluded that the market demands the refined edible oil with characteristics such as bland flavour and odour, clear appearance, light colour, Long Shelf Life, Suitable for frying since the Crude Oil obtained does contains many harmful factors like free fatty acids (FFA), sediments, gums, odoriferous

Get Price

2016-05-21 Shipping of Oil Refinery Plant and Oil Dewax Machines to Hongkong Hop Hing Group Vegetable Oil Refining Process & Technology Vegetable oils are obtained from a variety of oil bearing seeds, grains and nuts, such as soyeans, sunflower seeds, corn germ (maize), rape seeds, peanut (groundnut) kernels, coconut, palm kernels, canola, safflower

Get Price

The edible crude oil obtained from oil mill plants and solvent plants get refined in the vegetable oil refinery plants before it is utilized directly. The edible oil through the oil refining process gives color uniformity and appealing quality to the oil by removing unpleasant smell and undesirable factors from the oil.

Get Price

Oil Refinery Plant Introduction Oil Refining is a progress of removing the impurities such as phospholipids, FFA, pigment, off-flavor in cruel oil before edible application. Oil refining machine is used for producing the first or second-grade edible oil.

Get Price

Edible/Vegetable Oil Refining. Edible/vegetable oil refining is a step by step process. Refining oil removes phospholipids, pigments, off-flavors, free fatty acids and other impurities. The entire oil refining plant process comprises degumming/neutralization, bleaching, deoderization, and winterization. Chemical refining is performed in order to remove the fatty acids from the crude oil that is extracted from the seeds.

Get Price

Edible Oil Refinery Plant. CentPro is an established manufacturing company that offers a diverse range of process and chemical equipment for a plethora of industries. Our experience and expertise in offering the most effective, optimum, and reliable solutions related to edible oil refinery plant are unmatched.

Get Price

DVC Process Technologists is one of the leading manufacturer and supplier of Edible Oil Refinery and provides complete service including design, installation, commissioning and automation of vegetable oil refining plant for different crude vegetable oils. We have over 165+ Edible Oil Refinery installations worldwide.

Get Price

The video show that 1-10tpd edible oil refinery process.1-10tpd edible oil refinery plant is widely used to refine almost all kinds of oil extracted from oil seeds like sunflower seeds, linseeds

Get Price

State Of Art Of Continuous Deodorisation Plant, Deodorisation is the Final Stage of Refining to Remove Free Fatty Acids, Odour and Color Pigments to Produce Bland Oil with a Good Shelf Life. Brissun with an Experience of Fifteen Years in the Field of RICE BRAN oil & all Other Oils Deodorisation Has Perfected the art of deodorization.

Get Price

The oil refinery process involves the removal of impurities from crude vegetable oil to make it ideal for human consumption. The refinery process will vary based on whether the oil is going to be used as cooking oil or as fuel.

Get Price

Mini Oil Refining Plant Working Process. We have set up an edible oil refining and fractionation plant in Cote Dore. It exactly can produce the Olein and Stearin. Our engineers will send you a customized palm kernel oil refinery plant, altogether with the price list for you reference.

Get Price

Sunflower oil refinery plant includes a series process, such as degumming, neutralization, bleaching, deodorization and dewaxing Goyum is a well-known manufacturer of full-line sunflower oil refining plant.

Get Price

The oil refinery process involves the removal of impurities from crude vegetable oil to make it ideal for human consumption. The refinery process will vary based on whether the oil is going to be used as cooking oil or as fuel.

Get Price

What is Degumming Process in Oil Refining Plant?. Degumming process in oil refining plant is to remove gum impurities in crude oil by physical or chemical methods, and it is an oil purification process. After screw pressing and solvent extracting from oilseeds, crude oil mainly contains triglycerides and few non-triglyceride.

Get Price

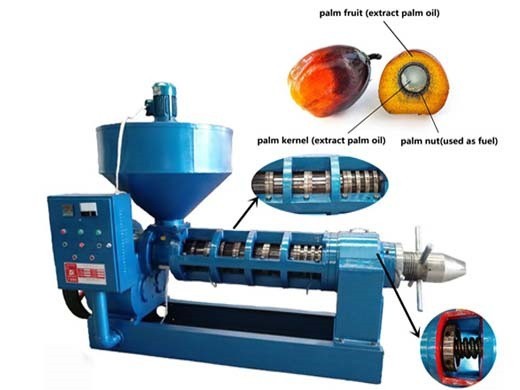

Palm oil refinery plant can refine various kinds of crude edible oil. Features advantages of palm oil refinery process machinery: 1. Customized capacity. We customize plant as per your requirement for the capacity. 2. Flexible usage. The plant can work independently or together with whole palm oil production line. Palm Oil Refinery Process

Get Price

Oil Refining is a progress of removing the impurities such as phospholipids, FFA, pigment, off-flavor in cruel oil before edible application. Oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining equipment.

Get Price

2016-05-21 Shipping of Oil Refinery Plant and Oil Dewax Machines to Hongkong Hop Hing Group Vegetable Oil Refining Process & Technology Vegetable oils are obtained from a variety of oil bearing seeds, grains and nuts, such as soyeans, sunflower seeds, corn germ (maize), rape seeds, peanut (groundnut) kernels, coconut, palm kernels, canola, safflower

Get Price

Production of raw material in the edible oil plant industry has shown an upward trend since 1997. By 2001, importation of raw material had dropped to 60 65% from a level of 95% in 1995. In 2001, 160,000 MT of locally available oilseeds were crushed and this scenario is projected to grow positively.

Get Price