I've worked in a refinery for almost 3 years now, and in the Oil & Gas industry for five. I'm not even close to knowing everything there is to know about running a refinery let alone building one. I'll do my best to answer. A good question but in...

On average, U.S. refineries produce, from a 42-gallon barrel of crude oil, about 19 to 20 gallons of motor gasoline, 11 to 12 gallons of distillate fuel, most of which is sold as diesel fuel, and 4 gallons of jet fuel. More than a dozen other petroleum products are also produced in refineries. Petroleum refineries produce liquids the petrochemical industry uses to make a variety of chemicals ...

Get Price

crude supply carries over into the refining sector. Some Cana-dians suggest, indeed expect, that with increasing crude pro-duction, Canada’s refining capacity should also grow. They ask why aren’t we refining more of our oil in Canada, and could we not get more value from our petroleum resources from more value added activity – i.e. refining?

Get Price

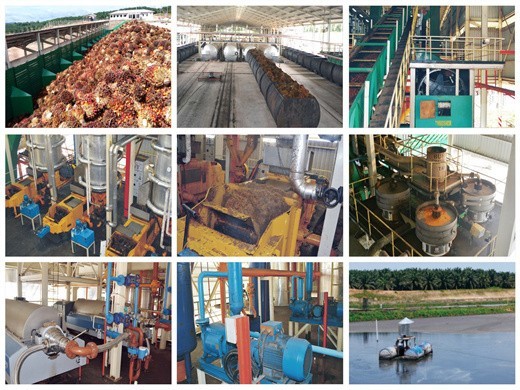

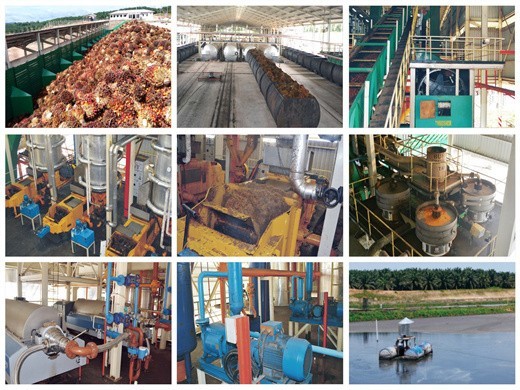

We are a company specialized in the production of grain and oil machinery.we have pretreatment, refining machine.We could process palm oil,peanut oil ...

Get Price

This approach offers cost savings over routine or time-based preventive maintenance, because tasks are performed only when necessary. “Plant predictive maintenance became a necessity where equipment can tell you when it needs maintenance and what is needed to be done. There is technology now that tells you there is maintenance to be done ...

Get Price

The local oil industry can play a role in the supply of sustainable and uninterrupted oil to consumers at their cost, plus the margin refining formula. There is no fixed margin and the margins are ...

Get Price

An oil refinery or petroleum refinery is an industrial process plant where crude oil is transformed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene, liquefied petroleum gas, jet fuel and fuel oils. Petrochemicals feed stock like ethylene and propylene can also be produced directly by cracking crude oil without the need ...

Get Price

Water is used in technological processes and also steam, heat and power production in oil refining industry. Water quality affects the lifetime and performance of equipment used in technological processes. Arionex offers complete solutions that ensure automated and controlled water treatment achieving necessary parameters and enabling efficient ...

Get Price

Cost on Starting a Palm Oil Refining Plant. Usually, the cost on starting a palm oil refinery plant should depend on what does it refines. Is it the crude palm oil or the refined bleached and deodorized palm oil. If the crude palm oil, also known as red oil, is needed, the palm oil refining plant may cost less than a plant that is for the ...

Get Price

An oil refinery or petroleum refinery is an industrial process plant where crude oil is transformed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene, liquefied petroleum gas, jet fuel and fuel oils. Petrochemicals feed stock like ethylene and propylene can also be produced directly by cracking crude oil

Get Price

Petroleum refineries convert crude oil and other liquids into many petroleum products that people use every day. Most refineries focus on producing transportation fuels. On average, U.S. refineries produce, from a 42-gallon barrel of crude oil

Get Price

Fractional distillation is the separation of a mixture into its component parts, or fractions. Chemical compounds are separated by heating them to a temperature at which one or more fractions of the

Get Price

Why Oil Refining Equipment Is Needed Why Oil Refining Equipment Is Needed. Oil refining equipment is a superior structural design, production methods, professional and technical maturity of high-quality machinery and equipment, compared to the production and production of edible oil

Get Price

The oil refining plant cost depends on what you want to process: Crude Palm Oil or RBD Palm Oil (Refined Bleached and Deodorised Palm Oil). If you want to set up a crude palm oil refining plant. The cost

Get Price

I've worked in a refinery for almost 3 years now, and in the Oil & Gas industry for five. I'm not even close to knowing everything there is to know about running a refinery let alone building one. I'll do my best

Get Price

Ballpark Estimate: $0.30 to $0.60 a gallon. With the high cost of filling your gas tank today, you might be interested in understanding the process and the real costs associated with getting the gasoline at your local station from the crude oil at the refineries. Oil

Get Price

The cost of conventional oil varies so much that Saudi Arabia into a deposit and a pump jack is put on it to help pull the deposit to the surface where it can be sent on for further refining.

Get Price

PALM OIL PROCESSING UNIT OPERATIONS. ‘Quality’ is entirely subjective and depends on the demands of the ultimate consumer. For the edible oil refining industry the most important quality criteria for crude oil are: capital equipment costs should be around US$10 000 to be affordable to village-based individuals or groups.

Get Price

Page 1 of 9 Refinery Equipment of Texas, LLC Crude Oil Refining A REOT Portable Diesel Fuel Plant can be operated in the oil field to produce fuel for diesel engines. It is simple-to-operate, easy-to-start, and easy-to-shut down.Fill your diesel storage tanks and shut the plant down until it’s needed

Get Price

An industry leader in Cannabis & Hemp (THC & CBD) oil refining & production Our equipment provides the highest purity oils, in an efficient and cost effective manner. Our ethanol based systems are highly automated, certified for all operations, GMP compliant and are a fraction the cost

Get Price

Oil Refinery: An industrial plant that refines crude oil into petroleum products such as diesel, gasoline and heating oils. Oil refineries essentially serve as the second stage in the production

Get Price

Oil refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as oil refineries) to transform crude oil into useful products such as liquefied petroleum gas (LPG), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils.

Get Price

mini mustard oil refining machine from india market,5TPD Mini Mustard Seeds Oil Plant Established in Imphal, Mustard Seed Oil Refine Plan Mustard Oil Mill Machinery Cost. The CEO of this company spoken highly of our oil pressing machine and mini crude oil refinery equipment, and the quality of produced mustard oil.

Get Price

You Won't Believe What Saudi Arabia's Oil Here's a look at why Saudi oil is as well as the associated equipment. The reason its capital costs are so low is that the country's oil is

Get Price

Rural refining of oil-bearing plants can produce fats and oils of good quality which provide needed energy and fat soluble vitamins. Commercial refining produces fats and oils that can be of high quality and have the characteristics of bland taste, clear colour, good keeping quality and frying stability.

Get Price

How much it will cost to set up a palm oil processing mill in Nigeria? Generally, the total cost of establishing a palm oil processing mill plant will be decided by many factors, including: the palm oil processing capacity, the quality and quantity of palm oil processing machines and equipment, the palm oil suppliers and more.

Get Price

Recent years, mini oil refinery machine becomes more and more popular among investors, not only because it has lower cost, but also because it is multifunctional. How much will cost to buy mini oil refinery machine for refining soya bean oil? You need

Get Price

Alfa Laval, Chempro, Silverson, and Zink Hamworthy are major edible oil process equipment manufactures. Conclusions: Commercial refining produces fats and oils that can be of high quality and have the characteristics of bland taste, clear color, good keeping quality and frying stability.

Get Price

Newest cooking oil processing, making, extraction, refining process technology, edible oil processing and refining steps introduction, cooking oil processing machine and edible oil refining machine, price, cost analysis and industry trend

Get Price

Steps in Oil and Meal Processing; The final step in refining any type of vegetable oil is deodorization. Steam distillation removes any compounds that could give the oil an unpleasant odour or taste. At this point, the canola oil is ready to be packaged and sold as a cooking oil,

Get Price

An explosion at one of the sprawling oil refineries in the area sent an 80,000-pound piece of equipment hurtling through the air before it landed just feet from a tank containing a modified version of hydrofluoric acid. It was a close call: Had the acid tank been smashed, a deadly chemical cloud could have devastated this bedroom community.

Get Price

Need for Keystone XL Erodes as U.S. Oil Floods Gulf Coast Refining Hub. creating a homegrown oil glut in the nation's refining center just as the Obama Administration prepares to rule on a

Get Price

HRI technicians can isolate hot equipment while it is still operating by installing blinds in connecting lines. While the unit is running, HRI can cut apart the line, insert a blind, weld a flange onto the line (if needed), bolt the line back together, and then make regular online repairs to the adjoining unit.

Get Price

Before learning the costs components of crude oil extraction, let's take a look at how producers extract crude oil from the ground.

Get Price

The oil refining process starts with a fractional distillation column. To understand the diversity contained in crude oil, and to understand why refining crude oil is so important in our society, look through the following list of products that come from crude oil: Petroleum gas used for heating,

Get Price

Engineering R&D: Simplified food-oil refining. March 26, 2003. Kevin T. Higgins. Alternative approaches that are more cost effective are needed, it is important to understand the proper vacuum practices to optimize your vacuum equipment’s performance. March 11, 2020.

Get Price