A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co‐product from the transesterification of soybean oil, was investigated in a pilot plant. The process was equipped with a static and a high‐shear mixer.

A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co-product from the transesterification of soybean oil, was investigated in a pilot plant. The process was equipped with a static and a high-shear mixer.

Get Price

A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co-product from the transesterification of soybean oil was investigated in a pilot plant. The process was equipped with a motionless and a high-shear mixer. The experimental studies explored the effects of variations in mixing intensity, temperature, reactant flow rates, and reactant stoichiometry on the ...

Get Price

A continuous process for the glycerolysis of soybean oil A continuous process for the glycerolysis of soybean oil Noureddini, H.; Harkey, D.; Gutsman, M. 2004-11-13 00:00:00 A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co-product from the transesterification of soybean oil, was investigated in a pilot plant.

Get Price

The optimal conditions were selected to be the basis for a continuous process: 40°C, a glycerol/oil molar ratio of 2:1, and an enzyme/oil ratio of 0.1 g enzyme/10 g oil. A definition for glycerolysis activity was adopted. The glycerolysis activity (1 GU) was defined as the amount of enzyme necessary to consume 1 µmol of substrate (glycerol ...

Get Price

Enzymatic glycerolysis of soybean oil was studied. Of the nine lipases that were tested in the initial screening, Pseudomonas sp. resulted in the highest yield of monoglycerides. Lipase from Pseudomonas sp. was further studied for the influence of temperature, thermal stability, enzyme/oil ratio, and glycerol/oil ratio. A full factorial ...

Get Price

Enzymatic glycerolysis of soybean oil was studied. Of the nine lipases that were tested in the initial screening, Pseudomonas sp. resulted in the highest yield of monoglycerides. Lipase from Pseudomonas sp. was further studied for the influence of temperature, thermal stability, enzyme/oil ratio, and glycerol/oil ratio. A full factorial optimization approach was performed. The following ...

Get Price

Enzymatic glycerolysis of soybean oil was studied. Of the nine lipases that were tested in the initial screening, Pseudomonas sp. resulted in the highest yield of monoglycerides. Lipase from Pseudomonas sp. was further studied for the influence of temperature, thermal stability, enzyme/oil ratio, and glycerol/oil ratio.

Get Price

Studies on the continuous glycerolysis of olive oil by the immobilized enzyme was done at 37°C in continuous stirred vessel bioreactor with polysulfone membrane. The effect of the flow rate of substrate (olive oil) in isooctane on the conversion and composition of the outlet was investigated using high‐performance liquid chromatography (HPLC).

Get Price

A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co-product from the transesterification of soybean oil, was investigated in a pilot plant.

Get Price

A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co-product from the transesterification of soybean oil, was investigated in a pilot plant. The process was equipped with a static and a high-shear mixer. The experimental studies explored the effects of variations in mixing intensity, temperature

Get Price

A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co‐product from the transesterification of soybean oil, was investigated in a pilot plant. The process was equipped with a static and a high‐shear mixer. The experimental studies explored the effects of variations in mixing intensity, temperature

Get Price

2004-11-13· A continuous process for the glycerolysis of soybean oil A continuous process for the glycerolysis of soybean oil Noureddini, H.; Harkey, D.; Gutsman, M. 2004-11-13 00:00:00 A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co-product from the transesterification of soybean oil, was investigated in a pilot plant.

Get Price

A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co-product from the transesterification of soybean oil, was investigated in a pilot plant. The process was equipped with a static and a high-shear mixer. The experimental studies explored the effects of variations in mixing intensity, temperature, reactant flow rates, and reactant stoichiometry on the

Get Price

A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co-product from the transesterification of soybean oil was investigated in a pilot plant. The process was equipped with a motionless and a high-shear mixer. The experimental studies explored the effects of variations in mixing intensity, temperature, reactant flow rates, and reactant stoichiometry on the

Get Price

A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co-product from the transesterification of soybean oil, was investigated in a pilot plant.

Get Price

A Continuous Process for the Glycerol is Is of Soybean Oil Free download as PDF File (.pdf), Text File (.txt) or read online for free.

Get Price

hydrotalcites have been studied in the oil glycerolysis batch processes [6-8]. MgO turns out to be a suitable catalyst in that process [6, 7]. We have studied a continuos glycerolysis of rapeseed oil over solid bases using a flow reactor with fixed-bed of a catalyst. Such insoluble mixed oxides as hydrotalcite, calcined hydrotalcite, MgO-TiO2,

Get Price

1998-10-01· Enzymatic glycerolysis of soybean oil was studied. Of the nine lipases that were tested in the initial screening, Pseudomonas sp. resulted in the highest yield of monoglycerides. Lipase from Pseudomonas sp. was further studied for the influence of temperature, thermal stability, enzyme/oil ratio, and glycerol/oil ratio. A full factorial optimization approach was performed. The following

Get Price

The optimal conditions were selected to be the basis for a continuous process: 40°C, a glycerol/oil molar ratio of 2:1, and an enzyme/oil ratio of 0.1 g enzyme/10 g oil. A definition for glycerolysis activity was adopted. The glycerolysis activity (1 GU) was defined as the amount of enzyme necessary to consume 1 µmol of substrate (glycerol

Get Price

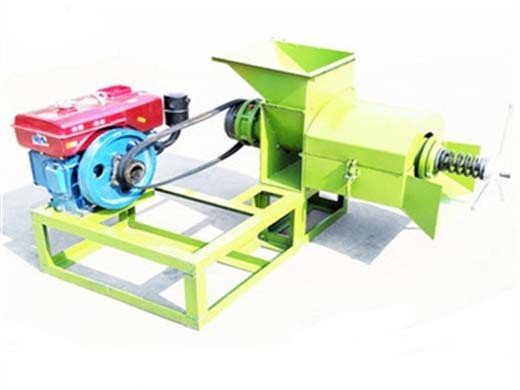

soybean oil machine price mini oil press machine, View mini. soybean oil machine price mini oil press machine, US $ 1,000 10,000 / Set, 1 Year, 12 Months, 100%, Peanut Oil.Source from Henan Eternalwin Machinery Equipment.

Get Price

Screw Oil Press Introduction. Screw oil press is a compact-structured oil extrusion machine used for extracting edible oil from more than twenty kinds of oilseeds such as peanut, soybean, flaxseed, sunflower seed, rapeseed, etc. Different from integrated screw oil press machine, it is more suitable to large-scale cooking oil plants which produce various grades cooking oil.

Get Price

Cold press oil expeller is equipped with disc fine filter to cold press peanut kernel, soybean, rapeseed, etc. The machine has large capacity and can also be used for hot pressing. The machine has large capacity and can also be used for hot pressing.

Get Price

Process of solvent extraction; Solvent extraction is the main process of oil extraction.In the extraction process, the full contact between the solvent and the embryo of the material is realized through a specific extraction device and a reasonable extraction mode, so as to achieve the purpose of fully dissolving oil and extracting oil.

Get Price

Oil Solvent Extraction Plant Soy Protein Project Section Introduction: We provides Turn Key Solution for Solvent Extraction Plant from 5TONS to 1000 TONS per day Capacity Solvent Extraction Plants are continuous and fully automatic intended for medium and large scale processing A modern desolventizer Toaster has always be

Get Price

continuous soybean oil solvent extraction machine in malis. Home. Best Soya Oil Press . continuous soybean oil solvent extraction machine in malis. soybeanoilmachine. Continuous crude cooking oil solvent extraction machine Process flow: The processes involved in the leaching process of the main vegetable oils include Oil extraction, wet meal desolventizing, mixed oil evaporation and

Get Price

A novel low temperature glycerolysis process for lowering free fatty acid (FFA) in crude jatropha oil for alkali catalyzed transesterification has been developed. The response surface methodology (RSM) based on central composite design was used to model and optimize the glycerolysis efficiency under three reaction variables namely; reaction time, temperature and glycerol to oil mass ratio.

Get Price

AOCS Press, USA. [AOCS] American Oil Chemists Society. 2003. AOCS Official Method Cd 8-53. Official Met-hods and Recommended Practices of the AOCS. 5th Ed. AOCS Press, USA. Brei V, Starukh G, Levytska S, Shistka D. 2012. Study of a continuous process of glycerolysis of rapeseed oil with the solid base catalysts. Chem Technol 6: 89-94.

Get Price

Conversion of Oils to Monoglycerides by Glycerolysis in Supercritical Carbon Dioxide Media Feral Temellia, Jerry W. Kingb,*, and Gary R. listb aDepartment ofAgricultural, Food, and Nutritional Science, University ofAlberta, Edmonton, Alberta T6G 2P5, Canada

Get Price

A novel low temperature glycerolysis process for lowering free fatty acid (FFA) in crude jatropha oil for alkali catalyzed transesterification has been developed. The response surface methodology (RSM) based on central composite design was used to model an...

Get Price

You are welcome to send us an email for more details of our oil plant. Mechanical Pressing Process(screw-press) Expeller is the key equipment of screw-press process, which is also known as screw oil press. Continuous screw pressing can deal with almost all kinds of oilseeds and nuts (soybean, cotton seed, copra, rice bran, palm kernel). Below

Get Price

ABSTRACT: The transesterification of soybean oil with glyc erol, 1,2-propanediol,and methanol by an immobilized lipase in flowing supercritical carbon dioxide for the synthesis of monoglycerides is described. A lipase from Candida antarctica was used to catalvze the reaction of soybean oil with glycerol, 1,2-propanediol,'ethylene glycol, and

Get Price

The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material's various nutritious ingredients when comparing with the leached oil.

Get Price

9389 products Soybean Oil Press Machine Price, Wholesale Various High Quality hot sale soybean screw oil press machine and soybeans oil screw press.Some information about soybean oil press and soya bean oil for great

Get Price

In order to process soybean oils from soybeans, soybean oil pressing machinery is necessary. Soybean oil press machine designed by our factory is the advanced oil processing machinery, characterized by the high oil output rate with good quality, simple design, easy to use and continuous operation. They also can be used for various raw materials

Get Price

In order to process soybean oils from soya beans, soybean oil pressing machine is necessary.Soybean oil pressing machine can be used for more than 20 kinds oil crops, such as sesame, peanut, soybean, black seed, sunflower seed, flax, vegetable seed, castor seed, cotton seed, rape seed, camellia seed, walnut, etc.

Get Price

Advantages of continuous soybean oil refining technology and soybean oil refining plant : The total oil refinery process is stable and only one time hydration can achieve second grade soybean oil. Continuous desolventization can also reach second grade soybean oil quality. This advanced edible oil refinery has superior advantages of short

Get Price

A novel low temperature glycerolysis process for lowering free fatty acid (FFA) in crude jatropha oil for alkali catalyzed transesterification has been developed. The response surface methodology (RSM) based on central composite design was used to model and optimize the glycerolysis efficiency under three reaction variables namely; reaction time, temperature and glycerol to oil mass ratio.

Get Price

Fresh Fruit Palm Oil Press Production Line Section Introduction: We can offer turnkey palm oil press plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing Our palm fruit oil processing plant capacity range from 3t h to 100t h with automatic palm oil

Get Price