This refining process can treat almost any kind of edible oils and fats but it involves the produc-ALKALI tion of soapstocks and has a refined oil yield lower than the one physically obtainable even if of more stable quality in the time. The standard steps in this refining process are: - NEUTRALIZATION

Advanced Canola Oil Refining Process - Offered by Oil Mill. Canola oil today is the most popular all-purpose vegetable oil across the world. Canola oil refining is quite a complicated oil processing process. Canola is distinguished from traditional rapeseed by the greatly reduced levels of the fatty acid, erucic acid and anti-nutritional ...

Get Price

Soybean oil refining process: 1. Hydration Degumming & Alkali Refining Deacidification Process Neutralization: The crude oil is output by the oil feed pump from the oil tank, and enters the crude oil heat exchanger to recover part of heat after metering and then is heated to the required temperature by the heater.

Get Price

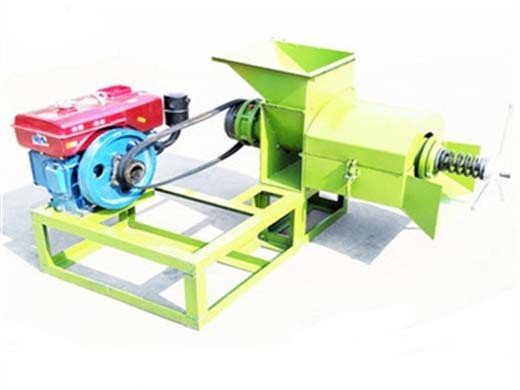

Vegetable oil processing is a complicated oil processing process.For different oil seeds the production process is diffent too. Vegetable oils are being processed by grinding, cooking, expelling and pressing, or by solvent extraction of the raw materials.

Get Price

Canola oil refining:Rapeseed oil refining mainly include hydration, alkali refining, bleaching and deodorization process, etc. Hydration means to remove or recycle the hydrophilic phospholipid from rapeseed oil, also called dephosphorization. Alkali refining is to purify crude canola oil, which is to add caustic soda solution to the crude oil ...

Get Price

The solvent extraction plant is designed to extract oil directly from oil seeds containing less than 20% oil, like soybeans, after flaking. Or it extracts oils from pre-pressed or fully pressed cake of seeds containing more than 20% oil like sunflowers, peanuts, cotton seed, palm kernels, canola, copra, castor and a variety of other materials.

Get Price

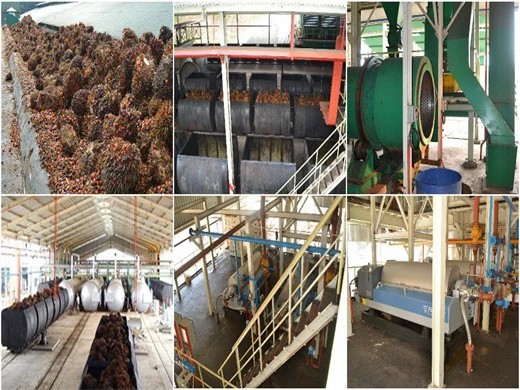

new design canola oil dewaxing machine in rwanda. canola oil machinery detail and Price. About canola oil machinery is an process for a complete palm oil mill equipment machinery, Palm oil mill design,providing full set of palm oil mill process machinery,advanced palm oil production processing technology ,sale crude palm oil process,palm oil refinery process ,lowest budget cost for building ...

Get Price

(You may also want know the Small Edible Oil Refining Cost >>) Oil Refining Production Process and Equipment. Before starting the oil refining, the crude oil must be filtered to remove the suspended solid materials, mainly oil cake residue, sand, fiber, etc. And some of the desolution materials, which are accumulated during the oil extraction ...

Get Price

Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil, etc. Machine Cost: $21,000~$115,000 (the exact price is based on capacity and other requirements of each equipment)

Get Price

It may also be mixed with other oils that are more solid by nature, including palm kernel oil. This process results in a semi-solid product that does not need to be further processed. Double pressed canola A small proportion of Canadian canola seed is processed

Get Price

Canola Oil Refining. Canola oil today is the most popular all-purpose vegetable oil across the world. Canola oil refining is quite a complicated oil processing process.Canola is distinguished from traditional rapeseed by the greatly reduced

Get Price

How to use oil refining machine? mini capacity cooking oil refinery machine mainly applied some small oil workshops or . https://goo.gl/RfJQzQ

Get Price

Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil, etc. Machine Cost: $21,000~$115,000 (the exact price is based on capacity and other requirements of each equipment)

Get Price

Advanced Renewable Fuel Alternative to Traditional Diesel. Produced from the Ecofining™ process, Honeywell Green Diesel meets or exceeds the most rigorous diesel performance standards, and can be made from a variety of sustainable feedstocks..

Get Price

BASICS OIL REFINING Gerrit van Duijn gerritvanduijn consultancy MVO course, June 2016 1. 2 Agenda Oils and fats sources Supply chains Refining or purification Degumming & neutralisation Bleaching Deodorisation Process routes Oil modification Hydrogenation Fractionation (canola) oil GD. 11 Palm and Palm Kernel Oil Palm fruit: Oil: 35

Get Price

Typically, the edible oil refining plant can be divided into three main types: batch oil refining, semi-continuous refining and continuous refining. Choosing which type for your edible oil refining line should assess the capacity, the purpose of final refined oils and detailed refining process.

Get Price

Robust, Efficient Refining Process: Natural oils and low-cost natural oil derivatives have specific chemical properties that provide additional value to fuel formulation; however, this value is generally lost as they are being processed. The JP χ processing technology maintains this inherent value of the natural oils and, as it can

Get Price

Advanced oil processing allows the player to obtain better ratios when refining oil. When the resultant recipe is enabled, the refinery input, and chemical plant's inputs

Get Price

Higher yields, lower costs in degumming. Enzymatic degumming is a well-established industrial process in vegetable oil refining. It gives higher yields and significant cost savings, and it’s easier on the environment. Enzymatic degumming converts gums into water-soluble lysolecithin.

Get Price

This refining process can treat almost any kind of edible oils and fats but it involves the produc-ALKALI In COLD REFINING the acid oil obtained from soapstocks generally has an acidity in the range lower refining costs.

Get Price

Canola oil extraction plant is equipped with refining equipment to produce high-quality healthy oil. 4. Suitable for small oil mill or small rapeseed oil processing plant. 5. The oil cake produced can be used for solvent extraction. 6. The Process of Canola Oil Processing Plant 1.

Get Price

Edible Oil Refining. Vegetable oil refining facilities process crude oils such as soybean oil, palm oil, rapeseed oil, canola oil, sunflower oil and other specialty oils including: peanut oil, olive oil and cottonseed oil. The processing converts them into oil for various consumer and industrial uses, for example, cooking oil, flavor

Get Price

Advanced Canola Oil Refining Process Offered by Oil Mill. Canola oil today is the most popular all-purpose vegetable oil across the world. Canola oil refining is quite a complicated oil processing process. Canola is distinguished from traditional rapeseed by the greatly reduced levels of the fatty acid, erucic acid and anti-nutritional

Get Price

Physical refining of soybean oil and canola oil is much more challenging, as these oils have the highest level of P, and can have the highest level of NHPs of all vegetable oils. EMI and Desmet installed physical refineries for soybean oil in Mexico and South America nearly 35 years ago.

Get Price

2017 Advanced Design Palm Oil Processing Plant With. by Wintone Machinery adopts advanced process design, india most advanced crude oil refining machine. Most advanced technology design groundnut oil Screen Crude Oil Tank Stork Advanced Palm Oil Processing Machine for most advanced

Get Price

use rapeseed oil refining machines for clean use oil to new hemp oil production line Process of rapeseed oil pressing Edible Oil Expeller Machinery Generally, rapeseed oil is widely used in machinery, rubber, chemical industry, plastics, paint, textile, soap making and medicine.

Get Price

Petroleum refineries convert crude oil and other liquids into many petroleum products that people use every day. Most refineries focus on producing transportation fuels. On average, U.S. refineries produce, from a 42-gallon barrel of crude oil, about 19 to 20 gallons of motor gasoline,11 to 12 gallons of distillate fuel,most of which is sold as diesel fuel,and 4 gallons of jet fuel.

Get Price

After extraction, the oil may contain undesired components that could have an effect on the taste, color or smell of the final product. The refining process is designed to effectively eliminate these components and create oil that is suitable for a variety of downstream applications.

Get Price

The optimized parameters in the bleaching process provide useful information for the development of industrial refining processes for canola oil and other oils. 2. Material and methods 2.1. Materials. The neutral canola oil exposed to degumming was obtained from a local oil

Get Price

Canola Seed Oil Refinery/refining Machine/plant/machinery Manufacturer,Find Complete Details about Canola Seed Oil Refinery/refining Machine/plant/machinery Manufacturer,Canola Seed Oil Refinery Manufacturer,Oil Refining Machine,Oil Refinery Machine from Oil Pressers Supplier or Manufacturer-.

Get Price

A wide variety of canola oil processing options are available to you, There are 878 suppliers who sells canola oil processing on Alibaba, mainly located in Asia. The top countries of suppliers are India, China, and Malaysia, from which the percentage of canola oil

Get Price

Introduction to Corn Oil Extraction Plant. Corn oil extraction plant extracts corn germ from corn and produces corn germ oil by solvent extraction method.The corn oil production line includes corn germ extraction process, corn germ pretreatment and prepressing process, corn germ cake solvent extraction process and crude corn germ oil refining process.

Get Price

Vegetable oil processing is a complicated oil processing process.For different oil seeds the production process is diffent too. Vegetable oils are being processed by grinding, cooking, expelling and pressing, or by solvent extraction of the raw materials.

Get Price

use rapeseed oil refining machines for clean use oil to new hemp oil production line Process of rapeseed oil pressing Edible Oil Expeller Machinery Generally, rapeseed oil is widely used in machinery, rubber, chemical industry, plastics, paint, textile, soap making and medicine.

Get Price

imarc imarcgroup. Vegetable Oil (Palm Oil, Canola Oil, Coconut Oil and Soybean Oil) Processing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost

Get Price

9.11.1.2 Process Description6-9 The following process description discusses only soybean oil manufacture, because emission factors are available only for that activity. Corn, cottonseed, and peanut oil processing are similar to soybean processing, except for differences in the soybean preparation for oil extraction. The process

Get Price

Improving Oil Extraction from Canola Seeds by Conventional and Advanced Methods Article (PDF Available) in Food Engineering Reviews · November 2025 with 515 Reads How we measure 'reads'

Get Price

With years experience in the field of oil and fats industry, KMEC is definitely your best partner for edible oil refinery. We’ve got professional oil refining engineers and advanced refining technologies, we will design, install and debugging the complete set of edible oil refinery plant according to customers’ refining needs to give the

Get Price

The solvent extraction plant is designed to extract oil directly from oil seeds containing less than 20% oil, like soybeans, after flaking. Or it extracts oils from pre-pressed or fully pressed cake of seeds containing more than 20% oil like sunflowers, peanuts, cotton seed, palm kernels, canola, copra, castor and a variety of other materials.

Get Price