A wide variety of biodiesel refinery options are available to you, There are 394 suppliers who sells biodiesel refinery, mainly located in Asia. The top countries of suppliers are Brazil, China, and Philippines, from which the percentage of biodiesel refinery supply is 1%, 98%, and 1% respectively.

Manufacturing Palm oil to biodiesel,Biodiesel, also named fatty acid methyl ester (FAME), is a clean renewable energy, which is a liquid fuel derived from chemical reaction between methanol and natural oil. The materials of biodiesel could be all kinds of animal and plant oil.

Get Price

China Crude Rapeseed Oil Biodiesel Transesterification Pharmaceutical Glycerol Making Plant Machinery, Find details about China Glycerol Refining Equipment, Crude Glycerol Purification Plant from Crude Rapeseed Oil Biodiesel Transesterification Pharmaceutical Glycerol Making Plant Machinery - .

Get Price

Small Biodiesel Making Plant Machine; Middle And Big Biodiesel Production Plant; Animal Oil Biodiesel Plant Machine; Used Cooking Oil Biodiesel Plant Machine; Palm Acid Oil Biodiesel Making Machine; Vegetable Oil Making Biodiesel Machine; Gutter Oil Biodiesel Plant Machine

Get Price

Process Advantages: 1 Multi-Feedstock Flexibility 2 Biodiesel of highest quality 3 Simple process management 4 Low operating costs Biodiesel introduction FAME ...

Get Price

Palm oil is used to produce both methyl ester and hydrodeoxygenated biodiesel. Palm oil methyl ester is created through a process called transesterification. Palm oil biodiesel is often blended with other fuels to create palm oil biodiesel blends. Palm oil biodiesel meets the European EN 14214 standard for biodiesels.

Get Price

gutter oil. Used cooking oil. And some Oily plant: Jatropha curcas, eucalyptus, palm etc. 2.Chemical technology biodiesel production processintroduction (1) Physical degumming: first of all, using oil hydration or phosphoric acid-etching method, remove the phospholipids and colloid and other substances, and then preheating, dehydration the oil.

Get Price

Biodiesel is a form of diesel fuel derived from plants or animals and consisting of long-chain fatty acid esters.It is typically made by chemically reacting lipids such as animal fat (), soybean oil, or some other vegetable oil with an alcohol, producing a methyl, ethyl or propyl ester.. Unlike the vegetable and waste oils used to fuel converted diesel engines, biodiesel is a drop-in biofuel ...

Get Price

About product and suppliers: 470 transesterification of oil to biodiesel machine products are offered for sale by suppliers on Alibaba, of which biodiesel accounts for 11%, mixing equipment accounts for 2%, and cleaning equipment parts accounts for 1%.

Get Price

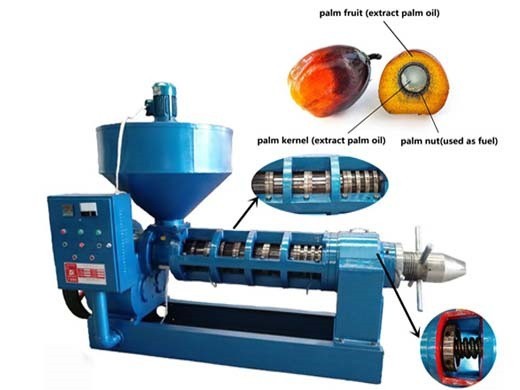

Palm oil to biodiesel, how ? However, crude palm oil derived from pressing contains many free fatty acid, which lengthen the time of direct esterification and consume vast alkaline catalyst and produce soda soap. Which means before biodiesel preparation, alkali refining, drying and

Get Price

We offer 150 biodiesel transesterification machine products. About 40% of these are biodiesel, 25% are oil pressers, and 10% are mixing equipment. A wide variety of biodiesel transesterification machine options are available to you, such as vehicles, liquid, and liquid with suspended solids.

Get Price

Biodiesel Transesterification Machine Glycerin Refine Biodiesel Distillation Equipment,Find Complete Details about Biodiesel Transesterification Machine Glycerin Refine Biodiesel Distillation Equipment,Used Cooking Oil Recycling Machine,Used Motor Oil Recycling Machines,Used Mobil Oil Recycling Machine from Supplier or Manufacturer-.

Get Price

We offer 240 transesterification of oil to biodiesel products. About 4% of these are Mixing Equipment, 16% are Oil Pressers, and 2% are Reactors. A wide variety of transesterification of oil to biodiesel options are available to you, such as condition, application, and additional capabilities.

Get Price

We offer 428 biodiesel oil refinery products. About 37% of these are Machine Oil Purifier, 18% are Oil Pressers. A wide variety of biodiesel oil refinery options are available to you,

Get Price

Home / Biodiesel Production Process By Palm Oil Biodiesel Production Process By Palm Oil Biodiesel, which is the fatty acid methyl ester, is a clean and renewable energy, in any natural oils as raw materials, processed with methanol by produced chemical liquid fuels.

Get Price

The analysis included the four main stages: oil palm plantation, palm oil production (crude palm oil extraction and palm oil refining), biodiesel production or transesterification into biodiesel (palm methyl ester or PME) and transportation at all stages. The analysis excluded the assessments of energy consumption associated with facilities construction i.e. manufacturing machines, irrigating

Get Price

2012-03-08· Top 7 Mistakes Newbies Make Going Solar Avoid These For Effective Power Harvesting From The Sun Duration: 7:14. LDSreliance Recommended for you

Get Price

Some of the most environmentally friendly biodiesel feedstocks are used cooking oil and waste grease. According to the EPA’s Renewable Fuel Standards Program Regulatory Impact Analysis, released in February 2010, biodiesel produced from waste grease results in an 86% reduction in greenhouse gases, compared to petro-diesel.

Get Price

China Crude Rapeseed Oil Biodiesel Transesterification Pharmaceutical Glycerol Making Plant Machinery, Find details about China Glycerol Refining Equipment, Crude Glycerol Purification Plant from Crude Rapeseed Oil Biodiesel Transesterification Pharmaceutical Glycerol Making Plant Machinery .

Get Price

2025-03-11· One of the key steps in the refining process is the elimination of impurities from crude vegetable oils, especially the phosphatides or so-called gums.

Get Price

Raw oil: vegetable oil, waste cooking oil, waste animal oil etc. Biodiesel production process. Biodiesel Process Characteristics. 1. The raw material is pretreated to dehydrate continuously, improving the conversion rate of esterification (transesterification), high production yield;

Get Price

The main concern of this paper is to produce biodiesel from palm oil by transesterification method and test the performance for different blends to analyze the fuel properties. Discover the world

Get Price

material of oil palm biodiesel comes from the derivatives of Crude Pa lm Oil (CPO) processed by refinery industry. Technologies commonly used commercially in producing biodiesel are

Get Price

The feedstock of biodiesel can be high free fatty acid oil (FFA≥3%,palm oil, used cooking oil, acidified oil, rice bran oil, etc.) or low free fatty acid oil (FFA≤2%,soybean oil, canola oil, etc.). Before feeding into transesterification section, we should control the FFA content below 0.1%.

Get Price

Studies on esterification of Free Fatty Acids in biodiesel production. UGent Francqui Chair 2013 / 2nd Lecture . 1 March 2013 . Contents • stIntroduction Link with 1 Lecture • Effect of FFAs in Vegetable Oils and Fats • Homogeneous processes for high FFA feeds • Heterogeneous catalysis for FFA conversion • Esterification in a Batch reactor • Esterification in a fixed catalytic

Get Price

. is a professional engineering modern enterprise specializing in various kinds of vegetable oilmaking machine, animal and fish oil production line, waste engine oil regeneration line, biodiesel production line, waste tires, plastics and rubbers pyrolysis line etc

Get Price

China Biodiesel Making Machine manufacturers Select 2020 high quality Biodiesel Making Machine products in best price from certified Chinese Recycling Machine manufacturers, Production Making Machine suppliers, wholesalers and factory on Made-in-China

Get Price

. is a professional engineering modern enterprise specializing in various kinds of vegetable oil, animal and fish oil production line, waste engine oil regeneration line, biodiesel production line, waste tires, plastics and rubbers pyrolysis line, essential oil and pigment extraction machine, has engineering design, equipment manufacture, technology

Get Price

. is a professional engineering modern enterprise specializing in various kinds of vegetable oilmaking machine, animal and fish oil production line, waste engine oil regeneration line, biodiesel production line, waste tires, plastics and rubbers pyrolysis line etc

Get Price

First generation biodiesels are produced from the edible feedstocks, example of edible feedstocks are Rapeseed oil, Soybean oil, Coconut oil, Corn oil, Palm oil, Mustard oil, Olive oil, Rice oil, etc. .Various feedstocks used for first generation biodiesel are illustrated in Table 1.Use of edible feedstock for the production of biodiesel is quite popular at beginning of biodiesel era.

Get Price

It is produced by subjecting SVO to a further refining process called Transesterification. The properties of biodiesel are covered by legislation such as American ASTM standards and European Standard EN14214. The Process There are therefore 4 processes carried out on oil used for this application. Although there are variations, and some

Get Price

Oil Refining Palm kernel oil refining machine Oil refining Palm Oil Refining Machine Small oil refining machine Copra oil refining machine Soybean Oil Refining Equipment Biodiesel Traditional Biodiesel Technology Biodiesel Non-acid Catalyzed Technology Protein Cottonseed protein machine Rice Bran Protein Soyabean protein Corn in-depth processing

Get Price

properties compared to palm oil [8]. Numerous [5], the Jatropha crude oil was suitable for biodiesel making. The biodiesel obtained from transesterification process had high qualities that reached the standards for vegetable oil- based fuels and could be used in diesel engines without modifications. Biodiesel has already been verified as suitable fuel for diesel engines. Biodiesel from

Get Price

In this study, sulphuric acid (H2SO4) was used in the pretreatment of sludge palm oil for biodiesel production by an esterification process, followed by the basic catalyzed transesterification

Get Price

Palm Tree Introduction: Palm trees are grown in tropical regions perennial oil crops,has the advantages of big yields low cost.Palm oil is already one of the world largest edibel oil production,is widely used in large food processing,cooking and eating areas of bio-diesel production.Oil palm tree main producing area distributes tropic area

Get Price

Palm oil is used to produce both methyl ester and hydrodeoxygenated biodiesel. Palm oil methyl ester is created through a process called transesterification. Palm oil biodiesel is often blended with other fuels to create palm oil biodiesel blends. Palm oil biodiesel

Get Price

4) Biodiesel By the transesterification process, the palm oil is reacting with the methyl alcohol. Then the biodiesel is got after the reaction. Palm oil is often mixed with the real diesel. Then it can be used in diesel energy. The quality of biodiesel which is made from the palm oil is high. At the same time, the FFA is got as the by-product.

Get Price

NATURAL ZEOLITE FOR TRANSESTERIFICATION STEP CATALYSTS IN BIODIESEL PRODUCTION FROM PALM OFF GRADE Sari Ulfayana1, Zuchra Helwani1 1Chemical Engineering Program, University of Riau, Pekanbaru

Get Price