The main disadvantage in biodiesel production is the high cost of the raw materials used, normally refined oils. Therefore, different feedstocks (waste, acid and frying oils) are being evaluated as possible substitutes. These alternative raw materials are less expensive, although being likely to appear more impure.

. is a professional engineering modern enterprise specializing in various kinds of vegetable oil, animal and fish oil production line, waste engine oil regeneration line, biodiesel production line, waste tires, plastics and rubbers pyrolysis line, essential oil and pigment extraction machine, has engineering design, equipment manufacture, technology ...

Get Price

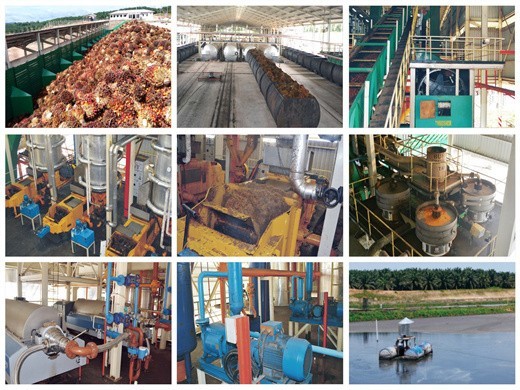

Biodiesel Production Line Type: high temperature preparation of biodiesel from high acid vegetable oil Processing Material: vegetable oil, Acidic Oil, Soap-stock, Oil residue, Waste Cooking Oil, Animal Oil Capacity: 10-500T/D. We're here to help: Easy ways to get the answers you need. ...

Get Price

. is a professional engineering modern enterprise specializing in various kinds of vegetable oil, animal and fish oil production line, waste engine oil regeneration line, biodiesel production line, waste tires, plastics and rubbers pyrolysis line, essential oil and pigment extraction machine, has engineering design, equipment manufacture, technology ...

Get Price

However, for biodiesel productions from low-grade vegetable oil feedstock containing high levels of FFAs (≥0.5 wt%) and water content above 0.3 wt%, acid catalysts are required to avoid soap ...

Get Price

Request PDF | Biodiesel production from high acid waste vegetable oil using homogeneous catalyst | Biodiesel is an environmental-friendly petroleum product currently being adopted by Oil and Gas ...

Get Price

• During the period 1992 to 2000 the net cost of biodiesel production from tallow in a large plant, including income from glycerol, would have been significantly more than the price of conventional diesel in each year, except only in 2000, and would have averaged about 52 cents per litre. The high cost of vegetable oils likely

Get Price

The oil has a high per centage of mono-unsaturation in fatty acid composition hence an excellent non-edible feedstock for biodiesel produc tion. The aim of this work is to model the production of biodiesel from E. lathyris using methanol and NaOH catalyst on an in silico platform.

Get Price

1. Introduction. Biodiesel is an attractive substitute for petro-diesel fuel because it is renewable and biodegradable. Biodiesel (usually fatty acid methyl esters, FAME) was often derived from either the transesterification of triglycerides or the esterification of free fatty acids (FFAs) with methanol , .The most practical technique is the transesterification in the presence of homogeneous ...

Get Price

A high quality biodiesel that fully met international specifications, except for the oxidation stability, was obtained as a result. Biodiesel productivity with the acid oil was much higher than that with the triglyceride-rich oil. This process permits the commercially realizable production of high quality biodiesel from acid oils.

Get Price

Biodiesel production line adopts high efficiency biodiesel technology at high temperature to obtain biological diesel oil as renewable source. This environmental protective and reproductive biodiesel is available under certain temperature, pressure, catalyst, and form fatty acid methyl ester, and through high vacuum distillation and rectification technology with high oil purity.

Get Price

Process steps. The major steps required to synthesize biodiesel are as follows: Feedstock pretreatment. Common feedstock used in biodiesel production include yellow grease (recycled vegetable oil), "virgin" vegetable oil, and tallow.Recycled oil is processed to remove impurities from cooking, storage, and handling, such as dirt, charred food, and water.

Get Price

Biodiesel Production Line Type: high temperature preparation of biodiesel from high acid vegetable oil Processing Material: vegetable oil, Acidic Oil, Soap-stock, Oil residue, Waste Cooking Oil, Animal Oil

Get Price

15-10-2010· Production of biodiesel from acid oil using sulfuric acid as catalyst: kinetics study The main disadvantage in biodiesel production is the high cost of the raw materials used, normally refined oils. an amount measured of oleic acid was added to the vegetable oil.

Get Price

Key words: Biodiesel, used vegetable oil, transesterification, alcohol. 1.Introduction Biodiesel is a fuel for diesel engines made from plant or animal oils. There are several sources of getting oil which is the raw material needed for biodiesel production and these include non-edible oil, animal fat and vegetable oil.

Get Price

The results supported that vegetable oil with high FFA can be used for biodiesel production by solid acid-catalyzed esterification followed by solid alkali-catalyzed transesterification. This study provided a friendly method to biodiesel production from raw feedstocks with high FFA.

Get Price

This process is not suitable for production of biodiesel from many unrefined non-edible vegetable oils because of their high acid value. Hence, a two-step esterification method is developed to

Get Price

The production of biodiesel from waste vegetable oils through its pretreatment followed by transesterification process in presence of methanol was investigated using a KM micromixer reactor. The parameters affecting biodiesel production process such as alcohol to oil molar ratio, catalyst concentration, the presence of tetrahydrofuran (THF) as a cosolvent, and the volumetric flow rates of

Get Price

This video discusses the different types of production methods used for transesterification and production of biodiesel, including batch type, semi-continuous and continuous-flow, plug flow and in

Get Price

We provide high quality Biodiesel Machine,Biodiesel Technology,Biodiesel Production Line with best price and reliable service. biodiesel from high acid vegetable oil Products

Get Price

Cost of biodiesel produced from virgin vegetable oil through transesterification is higher than that of fossil fuel, because of high raw material cost. To minimize the biofuel cost, in recent days waste cooking oil was used as feedstock. Catalysts used in this process are usually acids, base, and lipase. Since lipase catalysts are much expensive, the usage of lipase in biodiesel production is

Get Price

In this study, corn oil as vegetable oil, chicken fat and fleshing oil as animal fats were used to produce methyl ester in a biodiesel pilot plant. The FFA level of the corn oil was below 1% while those of animal fats were too high to produce biodiesel via base catalyst.

Get Price

Biodiesel is a class of transport fuel which includes Hydrogenated Vegetable Oil (HVO) and Fatty Acid Methyl Esters (FAME), produced from either vegetable oils or animal fats. Intended as a replacement for fossil-derived diesel, FAME biodiesel forms a significant component of the total renewable fuels

Get Price

Biodiesel is a diesel fuel that is made by reacting vegetable oil (cooking oil) with other common chemicals. Biodiesel may be used in any diesel automotive engine in its pure form or blended with petroleum-based diesel. No modifications are required, and the

Get Price

Energy Balance & Security Biodiesel production and use at home, biodiesel helps reduce the need for foreign oil. Toxicity, Biodegradability, Safety & Recycling Less toxic than table salt, biodiesel has minimal environmental impact. With a high flash point, biodiesel is safer to handle and store than petroleum diesel.

Get Price

Mg/Al for the jatropha oil12. The study for the production of biodiesel using nanoparticles as catalysts is very limited. To the best of our knowledge, there is no report available on biodiesel production from Pongamia pinnata oil with methanol using iron nanoparticles as a catalyst.

Get Price

The market for b iodiesel production from used cooking oils and fats, oils and Biodiesel: Refers to a vegetable oil or animal fat based diesel fuel consisting of long-chain alkyl esters. The general appeal of promoting biodiesel production from UCO is undeniable.

Get Price

We offer 1,465 acid oil for biodiesel products. About 4% of these are Palm Oil, 2% are Sunflower Oil, and 0% are Agricultural Waste. A wide variety of acid oil for biodiesel options are available to you, such as processing type, use, and packaging.

Get Price

Biodiesel Making Machine For Palm Oil Acid Value Oil Reuse Used Cooking Oil For Bio Diesel Line,Find Complete Details about Biodiesel Making Machine For Palm Oil Acid Value Oil Reuse Used Cooking Oil For Bio Diesel Line,Iodiesel Oil Production Line,Biodiesel Production Are Vegetable Oils,Biodiesel Production Are Animal Fats And Short Chain Alcohols from Supplier or Manufacturer

Get Price

Biodiesel has a higher flash point than fossil diesel and so is safer in the event of a crash. Biodiesel Production. As mentioned above biodiesel can be produced from straight vegetable oil, animal oil/fats, tallow and waste oils. There are three basic routes to biodiesel production from oils and fats: Base catalyzed transesterification of the oil.

Get Price

The continuous production of biodiesel (fatty acid methyl esters) by the transesterification reaction of coconut oil and palm kernel oil was studied in supercritical methanol without using any catalyst. Experiments were carried out in a tubular flow reactor, and reactions were studied at 270, 300, and 350 °C at a pressure of 10 and 19 MPa with various molar ratios of methanol-to-oils from 6

Get Price

Vegetable oil is a triglyceride, which means that its molecule consists of a glycerin “backbone” with three fatty acids attached, forming a shape like a capital letter E. To make biodiesel, we add lye and methanol. The highly caustic lye breaks the three fatty acid

Get Price

process high free fatty acid feedstocks using an acid-catalyzed pretreatment followed by an alkaline-catalyzed transesterification. Case studies of pilot plant-scale production of biodiesel from soybean oil, yellow grease with 9% free fatty acids, and brown grease with 40% free fatty acids are presented.

Get Price

Making Biodiesel From Waste Vegetable Oil: Maybe if Walt and Jesse had taken to making biodiesel rather than methamphetamine they would have had less trouble with the Mexican cartels, less murders and violence and an altogether easier life? Also a lot more environmentally friendly! There h...

Get Price

biodiesel production has some advantages. It is cheaper than edible vegetable oils and it is a way to valorize a sub-product. Nevertheless, these oils possess some contaminants, specially free fatty acid (FFA) content, which can reduce the quality and yield of biodiesel production.

Get Price

1. Introduction. Biodiesel is a fuel derived from vegetable oils or animal fat that is formed by mono-alkyl-esters of long chain fatty acids. It can be used for replacing fossil diesel fuel in whole or in part in compression ignition engines for automotive propulsion or energy generation [].One of the advantages of using biodiesel is the high cetane number compared to diesel.

Get Price

Home > Product Directory > Catalyst and Auxiliary > Chemical Auxiliary Agent > Carbon Black > Biodiesel production line waste vegetable oil biodiesel production machine small biodiesel plant. Add to My Favorite My Favorite Stores Contact Supplier

Get Price

The oil has a high per centage of mono-unsaturation in fatty acid composition hence an excellent non-edible feedstock for biodiesel produc tion. The aim of this work is to model the production of biodiesel from E. lathyris using methanol and NaOH catalyst on an in silico platform.

Get Price