Biodiesel is an alternative fuel for diesel engines. Patent invention production of biodiesel production is focusing on chemically processing and recovery technology from waste vegetal oil or animal oil or fat in urban catering pigwash.

Biodiesel Production Line. Type: high temperature preparation of biodiesel from high acid vegetable oil Processing Material: vegetable oil, Acidic Oil, Soap-stock, Oil residue, Waste Cooking Oil, Animal Oil Major equipment: esterification reactor, distillation column, condenser, reboiler, pressure vessel Application: biodiesel is a new type replacement fuel from renewable sources Capacity: 10 ...

Get Price

Oil Refining & Biodiesel Biodiesel. Production in a continuous process In classical plants, fats are transesterified in a two-stage batch process and is normally done in two subsequent batch containers.

Get Price

Glycerin Refining Equipment You are here: Home 禄 Biodiesel Production Equipment 禄 Glycerin Refining Equipment Glycerine workshop a full set of equipment, including the section of Glycerin purification, ion exchange column, evaporation dehydration,distillation, deodorization, decolorization.

Get Price

Arslan Enginery is having the complete process and technology of advanced (ATFE) process to produce biodiesel from all kind of crude vegetable oil. Today we have grown as a major force in Plant / Utility Design Consulting Engineering. Covering-Process, Equipment Layout, Piping, Stress Analysis, Electrical, Instrumentation, Project & Procurement Management with Construction support.

Get Price

We Can Offer Biodiesel Solutions, Turnkey Biodiesel Project Service, Provide Biodiesel Production Machine, A Professional And Best Biodiesel Equipment Plant Manufacturer In China. Biodiesel Solutions Biodiesel Projects most powerful biodiesel process equipment businesses in China.

Get Price

Nearly two years after the project was announced, a 5 MMgy supercritical biodiesel plant in Annawan, Illinois, is now operational. Designed and built by Jatrodiesel Inc., the innovative facility is co-located with the 125 MMgy CHS-owned Patriot Renewable Fuels ethanol plant, leveraging the existing refinery infrastructure, steam, and distillers corn germ oil byproduct for biodiesel feedstock.

Get Price

DIY Home Biodiesel Production: Make Your Own Fuel ... for making biodiesel with used cooking oil in a DIY biodiesel plant. ... the equipment youl need for home biodiesel production is a ...

Get Price

The B-500 Continuous Batch Biodiesel Plant produces 9000 gallons of Biodiesel daily, and has the capacity to produce 2.3 million gallons of Biodiesel annually. The B-500 Commercial Biodiesel Processor is the heart of the plant, with the addition of separation & washing Biodiesel equipment modules can operate 24/7. More B-500 Continuous Batch ...

Get Price

Our decade of experience building and operating biodiesel plants insures that we will design and build for you the right size plant, with the right equipment, installed and brought on line on time and within budget. Since 1996, Pacific Biodiesel has owned and operated biodiesel plants utilizing multiple feedstocks including used cooking oil

Get Price

Oil Refining & Biodiesel Biodiesel. Production in a continuous process In classical plants, fats are transesterified in a two-stage batch process and is normally done in two subsequent batch containers.

Get Price

Crown biodiesel pretreatment plants are designed for continuous operation as well as for maximum efficiency and safety. The process is similar to refining oil for edible use, but without some of the extras that are needed to make an edible product. The main goal of pretreatment is to reduce both the phosphatides and fatty acid of the feed to the biodiesel (transesterification) plant.

Get Price

Biodiesel Refining Oil Biodiesel Equipment/ Biodiesel Plant,Find Complete Details about Biodiesel Refining Oil Biodiesel Equipment/ Biodiesel Plant,Biodiesel Refining Oil Plant,Biodiesel Plant,Used Oil Biodiesel Equipment from Machine Oil Purifier Supplier or Manufacturer-.

Get Price

offers 290 biodiesel refinery equipment products. About 45% of these are machine oil purifier, 1% are other machinery & industry equipment. A wide variety of biodiesel refinery equipment options are available to you,

Get Price

offers 36 Biodiesel Refinery Plant Suppliers, and Biodiesel Refinery Plant Manufacturers, Distributors, Factories, Companies. There are 19 OEM, 22 ODM, 8 Self Patent. Find high quality Biodiesel Refinery Plant Suppliers on.

Get Price

offers 414 biodiesel refining equipment products. About 0% of these are Other Food Processing Machinery. A wide variety of biodiesel refining equipment options are available to you,

Get Price

Amigun & von Blottnitz (2005) that the optimum biodiesel plant size in South Africa ranges between 1500 and 3000 kg/h. Two types of plants were considered, namely a seed extraction biodiesel production (SEBP) plant using locally produced oilseeds as feedstock and a crude oil biodiesel production (COBP) plant using imported crude vegetable oil as feedstock. The capital investment for

Get Price

Appropriate site selection is a critical success factor for any biodiesel project. Among the many considerations for determining where to place your biodiesel plant are : Plant size If you are planning a large biodiesel operation, you will need sufficient land for your biodiesel equipment, your tank farm, and intake and off take traffic.

Get Price

SRS International Corporation is a leader in biodiesel technology specializing in turnkey biodiesel refineries (turnkey biodiesel plants). SRSteam of biodiesel engineers understand what it takes to run a profitable biodiesel refinery (biodiesel plant). Whether you have an existing biodiesel refinery (biodiesel plant), or you are looking to

Get Price

Sustainable Biodiesel Production Since there are multiple feedstocks from which to make biodiesel, plant operators can opt for the least expensive feedstock currently available, if they have a multiple-feedstock system. This flexibility makes producers less subject to price fluctuations. One example of this is noted by the prices of soybean oil

Get Price

Refining of crude biodiesel alone accounts for 600% of the total processing cost . Furthermore, dry washing technique (ion exchange resins and magnesol powder) was introduced to substitute water washing to remove biodiesel contaminants. This technique is also employed in commercial plants to purify biodiesel .

Get Price

Coconut Oil, Buy High Quality Coconut Oil Products From Global Coconut Oil Suppliers And Coconut Oil Manufacturers. Biodiesel Solutions Biodiesel Projects most powerful biodiesel process equipment businesses in China.

Get Price

12.04.2012· Unlike companies which manufacture biodiesel production equipment (biodiesel processor) based on outdated, tank technologies, which have been used for over a century, our company uses the high

Get Price

Biodiesel Production Equipment Our diesel plant is a case has absolutely abandoned the traditional ways of using sulfuric acid as the catalyst, completely solved the difficulty of corrosion. The biodiesel generated this way from waste oil can also reach the EU standards. Fatty Acid Methyl Ester Production Equipment Most waste animal and vegetable oil has high acid value while the acid value of

Get Price

. is a professional engineering modern enterprise specializing in various kinds of vegetable oil, animal and fish oil production line, waste engine oil regeneration line, biodiesel production line, waste tires, plastics and rubbers pyrolysis line, essential oil and pigment extraction machine, has engineering design, equipment manufacture, technology

Get Price

Biodiesel is an alternative fuel for diesel engines. Patent invention production of biodiesel production is focusing on chemically processing and recovery technology from waste vegetal oil or animal oil or fat in urban catering pigwash.

Get Price

A Tesoro oil refinery in Dickinson, North Dakota, has plans to co-process renewable feedstock along with regionally sourced Bakken crude oil to produce a 5 percent renewable diesel blend. Construction is planned for October with start-up in December.

Get Price

Glycerin Refining Equipment You are here: Home » Biodiesel Production Equipment » Glycerin Refining Equipment Glycerine workshop a full set of equipment, including the section of Glycerin purification, ion exchange column, evaporation dehydration,distillation, deodorization, decolorization.

Get Price

A California ethanol plant is being awarded a grant from the state energy commission to help build a biodiesel production facility on-site. Calgren Renewable Fuels, an ethanol refinery in Pixley, Californiahe heart of dairy countrylready features a recently constructed anaerobic digester that powers the facility 57 MMgy of ethanol production, and now the integrated biorefinery

Get Price

The new biodiesel facility is located next to Cargill oilseed processing plant and replaced an existing soybean oil refinery. Air Liquide Engineering & Construction was contracted for engineering, having already built six biodiesel plants for Cargill around the world using its Lurgi biodiesel

Get Price

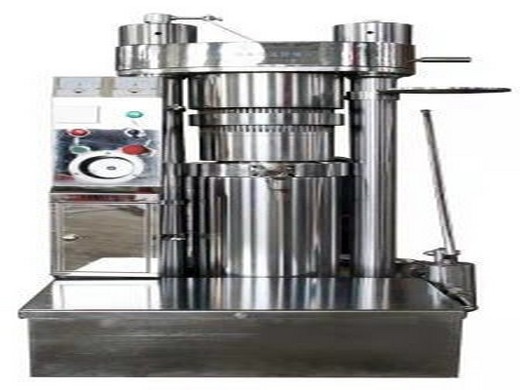

Application The biodiesel production equipment can be used for oil refining from organics such as waste animal and vegetable oil (used cooking oil), straw, food waste etc.

Get Price

Biodiesel Magazine is a quarterly trade journal dedicated to objective, independent coverage of biodiesel news, events and information relevant to the global industry. With editorial focus on U.S. and international methyl ester manufacturing, trade, distribution and markets, Biodiesel Magazine also provides valuable insight into feedstock and market share competition from the non-ester

Get Price

Biodiesel Making Machine, Biodiesel Plant, Biodiesel Machinery manufacturer / supplier in China, offering Biodiesel Making Machine Biodiesel Plant / Biodiesel Machinery / Biodiesel Equipment Biodiesel Processing and Production, Fog Cannon Fogging Machine/Dust Suppression Sprayer /Dust Remove Fogging Machine, Vehicle Mounted Agricultural Sprayers Fog /Water Mist Car Cannon

Get Price

Biodiesel has been produced on an industrial scale in the European Union since 1992. Biodiesel is a renewable fuel produced from vegetable oils such as rape seed oil, sunflower seed oil, soybean oil and also used frying oils (UFO) or animal fats. And even so the production of biodiesel is a complex process indeed, the glycerin that is being distilled during the production process can be used

Get Price

Used Biodiesel Plant with Capacity 1000 Litres Per Day. Stock #RG9548. Little used Green Fuels biodiesel plant with capacity 1000 litres/day from used cooking oil feedstock. Plant was built in 2013 and shut down in 2014 after very little use. Major equipment includes: Fuel Maker, BP60 ion exchanger purification module, Location: UK

Get Price

Biodiesel production line adopts high efficiency biodiesel technology at high temperature to obtain biological diesel oil as renewable source. This environmental protective and reproductive biodiesel is available under certain temperature, pressure, catalyst, and form fatty acid methyl ester, and through high vacuum distillation and rectification technology with high oil purity.

Get Price