5.Pressing (Extracting the palm oil) Palm fruit by stirring and squeeze broken by mashed tank, and then put into the screw press machine to press oil. Then, containing sand, water, and oil liquid part put into the purifier separation to get crude palm oil. The press cake (including fiber and nuclear) into the next process.

We provide high capacity crude palm oil processing mill,including palm fruit and kernel pressing,oil extraction,oil refining,oil fractionation,ensures high efficiency and high oil yield of edible palm

Get Price

Crude Palm Oil Mill Process Introduction:. 1.Weighing.Palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.Loading ramp.FFB after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank.

Get Price

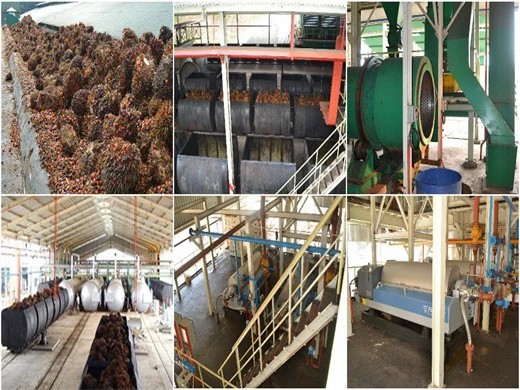

The palm oil extraction process involves a series of processes starting with harvesting fresh fruit bunches from the plantations and ending with crude palm oil storage. Through sterilizing, threshing, digesting and expelling, crude palm oil will be pressed out in palm oil pressing machine (screw oil press).

Get Price

Palm oil filtration process is very important process in the palm oil processing process, it refers to remove the unwanted impurities from the crude palm oil, such as fibers, sands, water and so on. Typically, the scale of the palm oil mills different, the process and machines used to filter crude palm oil will be different.

Get Price

After oil pressing or extracting, the oil then requires clarification in a filter press or by sedimentation. To ensure premium quality of final oil and by-products, palm oil mill should have strict quality control from fresh palm bunch processing to kernel oil extraction.

Get Price

Palm oil mill plant adopts the most scientific palm oil processing equipment configuration, using mechanical oil pressing technology, make successfully extraction of palm oil from palm fruit. Palm oil milling process plant covers three major plants of crude palm oil pressing plant, water treatment plant and power supply plant.

Get Price

If you are planning to set up a palm oil refining plant or oil refinery equipments, you are in the right place! We take the opportunity to introduce Goyum Screw Press, an ISO 9001 Company, a leading oil mill engineering firm, specialist in vegetable oil extraction and refinery field.

Get Price

Palm Fruit ( Kernel) Oil Processing Machine/Palm Oil Extraction Machine. Capacity 5-100T/H. Oilseed Palm Fruit/ Kernel. Application palm fruit (FFB) and palm bunches. Description Henan huatai palm oil processing main processes: weighing, unloading fruit, sterilizer, removing fruits, mashed, pressing, shell and kernel separation, water treatment, palm oil refinery and fractionation,filling.

Get Price

Palm oil mill process is quite different from other oil seeds processing. Palm oil mill process includes 6 parts: Palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery.Our palm oil mill process is low cost and energe-saving.

Get Price

That's the reason why palm fruit must be sent into processing in 24 hours. Palm oil mill process includes 6 parts: Palm bunches receiving, sterilizer, threshing, mashing and pressing, crude oil clarifying and palm kernel recovery. 1.

Get Price

Palm oil refining machine enables high quality edible vegetable oil refining processing from crude palm oil efficiently. Palm oil fractionation technology divides palm oil into liquid and solid oil by different welding points and different solution of various triglycerides composing oil. Palm Oil Mill Process Palm Kernel Oil Pressing

Get Price

The oil winning process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export.

Get Price

After oil pressing or extracting, the oil then requires clarification in a filter press or by sedimentation. To ensure premium quality of final oil and by-products, palm oil mill should have strict quality control from fresh palm bunch processing to kernel oil extraction.

Get Price

Palm oil is derived from the fruit of the oil palm tree, which is grown in tropical regions of Asia and Africa. While palm oil producers rely on different techniques to extract this oil, the basic steps involved in palm oil production remain the same.

Get Price

14.04.2016· Sinoder Group Supply Complete FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil) Threshing & Extraction Processing & Refining & Fractionation Machinery and Solution with Full Around

Get Price

We provide high capacity crude palm oil processing mill,including palm fruit and kernel pressing,oil extraction,oil refining,oil fractionation,ensures high efficiency and high oil yield of edible palm

Get Price

Crude Palm Oil Mill Process Introduction:. 1.Weighing.Palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.Loading ramp.FFB after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank.

Get Price

Palm oil mill plant adopts the most scientific palm oil processing equipment configuration, using mechanical oil pressing technology, make successfully extraction of palm oil from palm fruit. Palm oil milling process plant covers three major plants of crude palm oil pressing plant, water treatment plant and power supply plant.

Get Price

Apr 15, 2020 Palm oil processing machine is used to extract crude palm oil from palm fruit and get high oil yield palm oil. Palm oil processing machine, also called as palm oil extraction machine, are utilized in palm oil mill or palm oil pressing plant for effective palm oi production. The design and technology of palm oil mill plant are very important for its smooth operation and further

Get Price

Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0鈩?to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.

Get Price

The quality of crude palm oil is dependent on the care taken after harvesting, particularly on the handling of the FFBs. Figure 1. Fresh fruit bunches waiting for processing at palm oil mill. A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 60-100 tons

Get Price

Small Sacle Palm Oil Mill Plant 1-10 ton/d Mini Palm Oil Mill Plant 10-20 ton/d Small Palm Oil Mill Plant 1-30 ton/d Palm Oil Refining Equipment Unit; Complete Palm Oil Mill Plant fruit reception system sterilizing system threshing system digesting system pressing system crude palm oil clarification system bulk oil storage

Get Price

Palm Fruit ( Kernel) Oil Processing Machine/Palm Oil Extraction Machine. Capacity 5-100T/H. Oilseed Palm Fruit/ Kernel. Application palm fruit (FFB) and palm bunches. Description Henan huatai palm oil processing main processes: weighing, unloading fruit, sterilizer, removing fruits, mashed, pressing, shell and kernel separation, water treatment, palm oil refinery and fractionation,filling.

Get Price

The concept of Mecpro mill is using the latest in palm oil milling technology to enhance efficiency with low operating cost. Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a mill commonly handles 2.5 to 150 MT per hour of FFB.

Get Price

After being sent to the cracker, the shells are recovered and used as fuel for the boiler, whereas the palm kernels are transported to a silo where they are dried. The kernels are then ready for extraction of the crude palm kernel oil (PKO). The palm kernel cake (PKC) is sold as animal feed.

Get Price

Oil Storage. In large-scale mills the purified and dried oil is transferred to a tank for storage prior to dispatch from the mill. Since the rate of oxidation of the oil increases with the temperature of storage the oil is normally maintained around 50°C, using hot water or low-pressure steam-heating coils, to prevent solidification and fractionation.

Get Price

Huatai provides high capacity crude palm oil processing machine production line including palm fruit and kernel pressing, oil refining, oil fractionantion with guaranteed warranty and reliable service.

Get Price

Palm oil mill manufacturer in Nigeria, Malaysia and Indonesia. We are a leading palm oil mill manufacturer that provides advanced palm oil machines, efficient palm oil mill plant and professional palm oil mill turnkey service with good price for the worldscustomers, such as

Get Price

After oil pressing or extracting, the oil then requires clarification in a filter press or by sedimentation. To ensure premium quality of final oil and by-products, palm oil mill should have strict quality control from fresh palm bunch processing to kernel oil extraction.

Get Price

The oil palm plantation should therefore be closely linked, both geographically and organizationally, to a mill capable of processing the harvested fruit with minimum delay. The fruit is steam-sterilized, and the fruitlets are then stripped from the bunch. This operation is followed by pressing to recover the crude palm oil

Get Price

Crude Palm Oil Production Process. Type: palm fruit/bench oil pressing Processing Material: Palm fruit Processing Capacity: 5-120TPH Crude Palm Oil Mill Process Introduction: 1.Weighing.Palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.Loading ramp.FFB after a ramp sieved to remove

Get Price

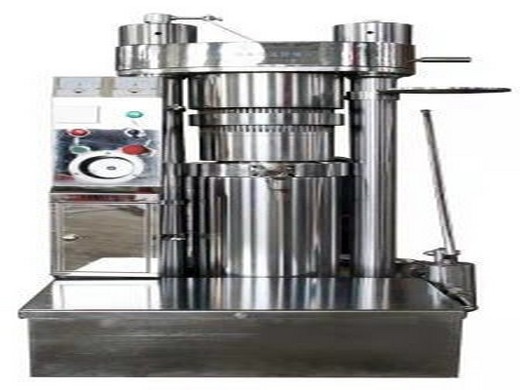

High quality professional palm kernel oil extraction machine palm oil milling machine for sale 0086-15238010724 Induction of New design professional palm oil processing machine palm oil extraction machine in high quality cheap price 0086-15238010724 The palm oil press which designed and produced by our research institute, is suitable for 3-15 hectares small farm or processing with

Get Price

Through sterilizing, threshing, digesting and expelling, crude palm oil will be pressed out in palm oil pressing machine (screw oil press). Each station of palm oil extraction machine uses different methods and machines. After purifying and refining, the refined palm oil can be exported as a popular kind of healthy and edible oil.

Get Price

The palm fruits are as bunches when arriving the fruit reception/receiving station of palm oil extraction plant. Before the processing of oil extraction, they are weighed in trucks by use of weighbridges. It should be underlined here that the quality of final palm oil is initially affected by the quality of bunches arriving at the palm oil mill. The palm oil extraction process or machine can

Get Price

Oil processing equipments of oil mill plantAccording to the mechanical power, these equipments extract oil from the oil material by pressing. The typical oil extraction press is usually one ofPalm Oil Mill Plant Palm

Get Price

Alvan Blanch offer small scale plants (0.5t/h) as well as 3 tonne and 10 tonne per hour plants for small to medium scale industries.. Palm Fruit & Kernel processing of all

Get Price

Safety Of 6YL Oil Pressing Machinery Production. Safety of 6yl oil pressing machinery production, following are strictly requested to be obeyed. 1. During operating, hands or metal rods are strictly prohibited to enter the hopper to touch cakes. 2. Tightening the screw shaft to its dead end is prohibited before starting or during operating

Get Price