Crude Palm Oil Refinery Plant. In the process of refinement (small palm oil refinery plant), there are three sections involvedamely: dry degumming, bleaching, and distillation andlor deodorization. First, the crude palm oil is mixed in a retention vessel together with phosphoric acid. The precipitated materials are handed to the bleaching section with the oil.

Our palm oil refinery plant refines the crude red palm oil and transforms it into edible refined transparent oil. The series of refining processes are conducted in our palm oil refinery plant. At every stage of refining, the palm oil changes its state and improves its quality.

Get Price

Palm Oil Refinery. Major equipment: Magnetic drum, Cleaning sieves, Sheller, Crusher, Flaking roll, Cooker, Softening pot, Puffing machine, Plate type drier. Application: High Efficiency Oil Refining From Crude Palm Oil With Low Energy Consumption and Oil Yield.

Get Price

Usually, the cost on starting a palm oil refinery plant should depend on what does it refines. Is it the crude palm oil or the refined bleached and deodorized palm oil. If the crude palm oil, also known as red oil, is needed, the palm oil refining plant may cost less than a plant that is for the refined bleached and deodorized palm oil.

Get Price

Crude palm oil refinery plant is used to refine palm oil to edible oil.Qie GROUP offer mini, small scale palm oil refinery palnt,offer turn-key solutions for crude palm oil refinery plant,adopts physical and chemical refining methods to refine palm

Get Price

Definition: Palm oil is edible oil which is extracted from the pulp of fruit of oil palms. The color of pulp is red. That's why crude palm oil is naturally similar to pulp color because of high inactive vitamin A content. It is different from kernel oil or coconut oil. Commonly it is combined or mixed with coconut oil to make highly saturated vegetable fat, which is also used for cooking purposes.

Get Price

Palm Oil Bleaching Process. The crude oil feedstock is heated and mixed with food grade phosphoric acid 85% concentration with an amount of 0.08% to 0.1% of crude oil quantity at a temperature range of 8020掳C of in a dynamic mixer. The mixture is fed into a degumming vessel with a retention time of 5 -15 minutes.

Get Price

Palm Oil Refinery Flow Chart: Basing on the traditional oil refining technology, our company has developed the latest combined packing layer plate deodorization soft tower and the physical and chemical mixed refining technology for crude oil of any quality.

Get Price

New Type Palm Oil Refining Plant/Superior Edible Oil 2Tcrude Palm Oil Refining Plant/Palm Oil Refinery, US $ 2,100 - 24,000 / Unit, 1 year, 12 Months, New, lard tallow refinery eeuipment.Source from . on.com.

Get Price

The kernel oil when extracted from the kernel oil mill plant is full of impurities and other substances. We manufacture superior range of palm kernel oil refining systems. Crude Palm Oil Refinery Flow Palm Oil Refining Line Plant The Palm Kernel Oil Refinery Equipments have the following: Equipment and System for Neutralization

Get Price

This is the fat that is squeezed out of the fruit from oil palm trees, hence you'll also see it called "palm fruit oil." It is rich in vitamin E. Refined palm oil has a red coloring, this is good, as the coloring comes from the antioxidant beta-carotene. It is an edible oil. Crude palm oil is widely used for soap manufacturing, vanaspathi etc.

Get Price

Degumming is the initial stage of refining used to separate gums, pigments, and trace metals from the crude oil by mixing the crude palm oil with concentrated phosphoric acid in order to avoid

Get Price

of red palm oil with sunflower oil showed better acceptability than using 100% red palm oil. As these preparations were made using crude red palm oil, the strong fruity odour was slightly less well-accept-ed, unless masked by the other in-gredients and the added flavours in the processing. BiO-availaBility OF b-carOtene FrOm red palm Oil

Get Price

Palm Oil Bleaching Process. The crude oil feedstock is heated and mixed with food grade phosphoric acid 85% concentration with an amount of 0.08% to 0.1% of crude oil quantity at a temperature range of 8020掳C of in a dynamic mixer. The mixture is fed into a degumming vessel with a retention time of 5 -15 minutes.

Get Price

processing conditions to be used for refining. Mild processing conditions minimise the formation of trans fatty acids during deodorisation and enable more of the natural antioxidants (tocopherols and tocotrienols) to be preserved in the final refined oil. Back to Start Crude palm oil and the DOBI Page 5 of 5

Get Price

The kernel oil when extracted from the kernel oil mill plant is full of impurities and other substances. We manufacture superior range of palm kernel oil refining systems. Crude Palm Oil Refinery Flow Palm Oil Refining Line Plant The Palm Kernel Oil Refinery Equipments have the following: Equipment and System for Neutralization

Get Price

Red palm oil is one of the latest superfoods that has those who are health-oriented in our society or within the natural health community talking. In the midst of breaking through the myth that all saturated fat is bad, we are now more willing and eager in fact, to consider tropical oils like red palm oil, which is primarily saturated fat-based.

Get Price

Palm kernel oil contains soap grade and food grade.The process of Palm kernel oil refinery is to refine the crude edible oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.The process of palm kernel oil refinery includes mechanical refinery method, chemical

Get Price

Refining, Bleaching, Deodorizing And Packaging Of Palm Kernel Oil In Nigeria, The Feasibility Report. Refining, Bleaching, Deodorizing And Packaging Of Palm Kernel Oil In Nigeria, The Feasibility Report. refining process is limited to simple physical treatment such as heating and filtering in regard to refining of superior quality of

Get Price

Refining is an essential process for a complete palm oil processing line because there are still some impurities such as phospholipids, FFA, pigment, odor,etc. in the crude palm oil. As a prominent oil processing machines manufacturer who is devoted to processing pure edible oil for worldwide customers, we can product and offer professional

Get Price

In a short span of 2 years again we installed 8 plants upgrading each time to meet the ever changing technology needs of the industry. The need of the hour in industry is plant which can cater to variety of oils like palm oil, palm kernel oil, soybean oil, cottonseed oil, corn germ oil, rapeseed oil, sunflower oil, etc.

Get Price

Palm oil refinery mill plays a very important role for the total palm oil production in the world. Our company, Machinery, has specialized in this sector for years. Now, with experienced professionals and development team, we are capable of providing very wide range of palm oil refinery plant and palm oil production machine for international market.

Get Price

Effect of type of bleaching earth on the final color of refined palm oil. Crude palm oil has to be refined to achieve desirable characteristics, such as a light color, (This paper presents a complete review on palm oil refining procedures, including its main problems such as the color fixation discussed in our work. In fact, this work

Get Price

of red palm oil with sunflower oil showed better acceptability than using 100% red palm oil. As these preparations were made using crude red palm oil, the strong fruity odour was slightly less well-accept-ed, unless masked by the other in-gredients and the added flavours in the processing. BiO-availaBility OF b-carOtene FrOm red palm Oil

Get Price

Refining, Bleaching, Deodorizing And Packaging Of Palm Kernel Oil In Nigeria, The Feasibility Report. Refining, Bleaching, Deodorizing And Packaging Of Palm Kernel Oil In Nigeria, The Feasibility Report. refining process is limited to simple physical treatment such as heating and filtering in regard to refining of superior quality of

Get Price

In a short span of 2 years again we installed 8 plants upgrading each time to meet the ever changing technology needs of the industry. The need of the hour in industry is plant which can cater to variety of oils like palm oil, palm kernel oil, soybean oil, cottonseed oil, corn germ oil, rapeseed oil, sunflower oil, etc.

Get Price

Soybean oil refining machinery Date:2013-11-09 19:20:11 / Edible Oil Refinery Plant / Give me the price / Leave a message 30tpd soybean oil refinery plant. The process of soybean oil refining is to refine the crude soybean oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.

Get Price

Red Palm Oil directory Red Palm Oil manufacturers, suppliers Red Palm Oil buyers, importers, wholesalers, distributors (as palmitic) 5% max M&I 0.5% max IV (Wijs) 51 - 55 Crude Palm Oil is an edible oil that is extracted from the pulp of oil palm fruits and it is an important vegetable oil that is used as the TYS Series Palm Oil

Get Price

Health Benefits of Palm Oil. Palm oil is extracted from either the pulp or the seed of the fruit. The fruit pulp oil is edible and can be used in cooking while palm kernel oil is a key ingredient

Get Price

Two processes have been developed for continuous refining of edible oils i.e. chemical refining and physical refining. Vegetable Oil Refinery Plant- Physical Refining: Our physical method of refining removes the Free Fatty Acids in single stage of deodorization process while the gum content from the crude oil is removed in the degumming process.

Get Price

Palm oil refinery mill plays a very important role for the total palm oil production in the world. Our company, Machinery, has specialized in this sector for years. Now, with experienced professionals and development team, we are capable of providing very wide range of palm oil refinery plant and palm oil production machine for international market.

Get Price

The kernel oil when extracted from the kernel oil mill plant is full of impurities and other substances. We manufacture superior range of palm kernel oil refining systems. Crude Palm Oil Refinery Flow Palm Oil Refining Line Plant The Palm Kernel Oil Refinery Equipments have the following: Equipment and System for Neutralization

Get Price

The quality and design of palm oil production line is the key to the quality of palm oil and also the crucial to the success of your palm oil business. Machinery is a professinal manufacturer and supplier of palm oil production equipment including palm oil extractor and machiner for chemical refining of palm oil, we are also good at offering turnkey production plan for complete sale of

Get Price

A novel process involving pretreatment of crude palm oil, followed by deacidification and deodorization using molecular distillation, can be used to produce a carotenerich refined edible palm oil. The product is a refined red palm oil that meets standard refined edible oil specifications and retains up to 80% of the carotene and vitamin E

Get Price

It is minimally processed from red palm fruit by steaming, expeller pressing and then cold-filtering to remove the strong odor and scent. The other key distinction between refined palm oil and red palm is that unrefined palm oil is RED in color because the nutrients have not been removed.

Get Price

Palm Oil Production Line/Palm Oil Processing Plant. Palm oil production line includes three sections, palm oil pressing plant, palm oil refinery plant and palm oil fractionation plant. As the manufacturer of the palm oil production line, we can offer the whole line or part of the palm oil production line for different capacities with turnkey

Get Price

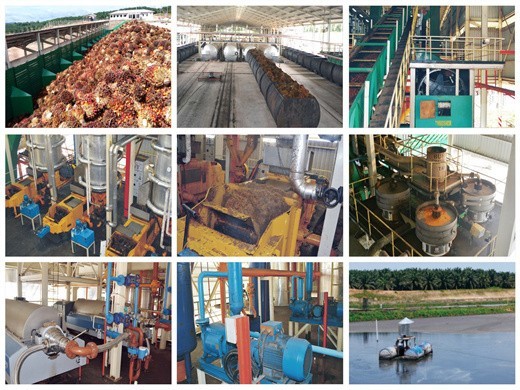

The palm oil processing process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export. 1-5tph palm oil processing plant

Get Price

Palm Oil Processing Oil Refinery Plant. Jul 31, 2012 Palm oil processing is not as easy as oil extraction from other oil bearing materials. The entire process starts with sorting of the s as soon as they arrive in the palm oil processing plant.

Get Price

excavation site to the crude oil refining industrial plant. 2. LNG Carrier: The LNG Carriers are those tanker ships that are used to cargo LNG or Liquefied . cargo which require a high standard of tank cleaning, such as palm oil, vegetable oils Some of the effects of oxidation may be rectified within an edible oil refinery . of the storage

Get Price