Crystallization properties of palm oil by dry fractionation Article in Food Chemistry 86(2):245-250 · June 2004 with 1,196 Reads How we measure 'reads'

Dry fractionation, also known as crystallization from the melt, is fractional crystallization in its simplest form. The features of the technology allow it to be used for the production of commodity fats. Dry fractionation has long been regarded as an unpredictable, tedious and labor-intensive process. However, the relatively cheap dry ...

Get Price

The dry fractionation process is simply a controlled crystallization of the melted oil, followed by separation of solid from liquid fraction. Three steps are involved in crystallization process; super cooling of the melt, nucleation and crystal growth ( Zaliha et al., 2004 ).

Get Price

Dry fractionation of coconut oil using 120 kg-scale crystallizer to produce concentrated medium chain triglycerides (FRAKSINASI KERING MINYAK KELAPA MENGGUNAKAN KRISTALISATOR SKALA 120 KG UNTUK ...

Get Price

Dry fractionation of coconut oil by melt crystallization. The dry fractionation process is a new and promising technique for these purposes . It is considered as an environmental friendly and cost-effective method as it is a physical process based on the crystallization from the melt without chemical addition ( Ulrich, 2004 ). Get Price

Get Price

Fractionation which separates the olein (liquid) and stearin (solid) fractions of oil is used to modify the physicochemical properties of fats in order to extend its applications. Studies showed that the properties of fractionated end products can be affected by fractionation processing conditions. In the present study, dry fractionation of palm-based diacylglycerol (PDAG) was performed at ...

Get Price

The dry fractionation process is simply a controlled crystallization of the melted oil, followed by separation of solid from liquid fraction. Three steps are involved in crystallization process; super cooling of the melt, nucleation and crystal growth (Zaliha etal.,2004). The separation is an important step since the amount of liquid fat entrapped

Get Price

The purpose of the present invention is to provide a method, whereby, in the dry fractionation of an oil or fat, a decrease in solid-liquid separation efficiency, said decrease being caused by the engulfment of a filtrate fraction into a crystal fraction after crystallization and press filtration, can be prevented and thus the crystal slurry can be efficiently separated after the crystallization.

Get Price

Emulsions and crystallization are two independent research topics which normally do not overlap although a combination of the two could be applicable to many areas. Here, the importance of emulsions in the field of fat crystallization is described. Three applications with industrial relevance were chosen for investigation: fat fractionation ...

Get Price

Layer melt crystallization was applied for the dry fractionation of multi-component mixtures using coconut oil as a model substance. The aim of the experiments was to optimize the crystallization parameters (e.g. crystallization temperature, melt temperature, cooling rate, agitation speed) in order to obtain the solid fraction with a higher melting temperature and solid fat properties.

Get Price

Layer melt crystallization was applied for the dry fractionation of multi-component mixtures using coconut oil as a model substance. The aim of the experiments was to optimize the crystallization

Get Price

Layout for Oil Palm Dry Fractionation Method . Crystallization Technique. The RBDPO Feed Oil is pumped to the Crystallizer. The fractionation system is batch type made up of vertical cylindrical vessel full of thermo-regulated water which is fitted with a

Get Price

The dry fractionation process is simply a controlled crystallization of the melted oil, followed by separation of solid from liquid fraction. Three steps are involved in crystallization process; super cooling of the melt, nucleation and crystal growth ( Zaliha et al., 2004 ).

Get Price

Crystallization properties of palm oil by dry of cooling treatment on the crystallization and fractionation of coconut monitoring of palm oil crystallisation from melt.

Get Price

Dry fractionation, also known as crystallization from the melt, is fractional crystallization in its most simple form, and the economy of the technology allows it to be used for production of commodity fats. Dry fractionation has long been regarded as an unpredictable, tedious and labor-intensive process.

Get Price

Crystallization properties of palm oil by dry fractionation. (1989). Nucleation from palm oil melt. In Proceeding of the PORIM international palm oil development conference (pp. 60–64), A.M TaylorThe crystallization and dry fractionation of Malaysian palm oil. Oleagineux, 3 (1976), pp. 73-79.

Get Price

Dry fractionation of coconut oil by melt crystallization. The dry fractionation process is a new and promising technique for these purposes . It is considered as an environmental friendly and cost-effective method as it is a physical process based on the crystallization from the melt without chemical addition ( Ulrich, 2004 ). Get Price

Get Price

Dry fractionation, also known as crystallization from the melt, is fractional crystallization in its simplest form. The features of the technology allow it to be used for the production of commodity fats. Dry fractionation has long been regarded as an

Get Price

For fat fractionation and phase change materials, emulsification can be applied as a tool to improve the fat crystallization process, and thus the product quality of the crystallized fat. Furthermore, the use of emulsification creates new application fields such as solid lipid nanoparticles in the area of fat crystallization.

Get Price

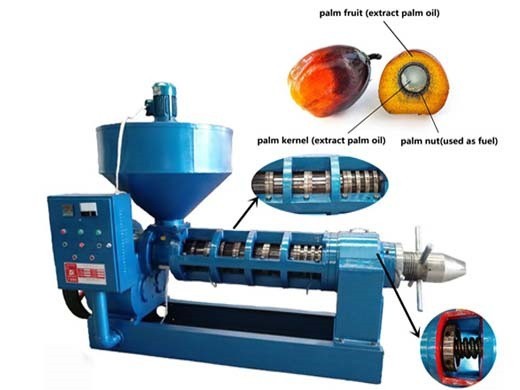

Palm oil fractionation goes through the control of palm oil cooling and crystallization to make separation of palm oil into low melting point liquid (soft fat) and high melting solid (sterin). Fractionation of palm oil can be divided into three fractions: stearin (palmstearine), soft fat (palmolein) and middle section (palmmidfraction).

Get Price

When oil is gently cooled, crystals will form spontaneously in the melt. After sufficient maturation time, these crystals can be filtered from the remaining liquid fraction, and this process thus results in 2 products: a solid fraction enriched in high melting crystals,

Get Price

Many companies that carry materials for making cosmetics stock fractionated coconut oil, and it can also be purchased from massage and soap suppliers. The dry fractionation of coconut oil includes crystallization section and filtration section.

Get Price

Fractionated coconut oil is coconut oil that has been processed or “fractioned” to create a very shelf-stable oil. The fraction of the oil that is used is very high in

Get Price

Coconut oil contains only 6% monounsaturated and 2% polyunsaturated fatty acids. In the partial hydrogenation process, some of these are transformed into trans fatty acids. Fractionation. Fractionated coconut oil provides fractions of the whole oil so that its different fatty acids can

Get Price

The purpose of the present invention is to provide a method, whereby, in the dry fractionation of an oil or fat, a decrease in solid-liquid ,separation efficiency, said decrease being caused by the engulfment of a filtrate fraction into a crystal fraction after crystallization and press filtration, can be prevented and thus the crystal slurry can be efficiently separated after the crystallization.

Get Price

Fractionation which separates the olein (liquid) and stearin (solid) fractions of oil is used to modify the physicochemical properties of fats in order to extend its applications. Studies showed that the properties of fractionated end products can be affected by fractionation processing conditions. In the present study, dry fractionation of palm-based diacylglycerol (PDAG) was performed at

Get Price

The historical development of fractionation, from the use of fractionated tallow in Mège‐Mouriès' margarine to the modern dry fractionation process used to produced steep‐melting palm fractions for cocoa butter equivalents, is described. The principles of fractionation

Get Price

Abstract: The purification and separation of durene from the mixture containing durene isomers were studied. Since the boiling points of tetramethyl benzene isomers are very close but theirmelting points are of great differences, static melt crystallization was applied to

Get Price

The historical development of fractionation, from the use of fractionated tallow in Mège‐Mouriès' margarine to the modern dry fractionation process used to produced steep‐melting palm fractions for cocoa butter equivalents, is described. The principles of fractionation

Get Price

It seems that, of these technologies, oil fractionation is definitely the ideal choice, thanks to its low operating costs, zero oil loss and reversibility. KMEC supplies a state of the art oil modification plant that is known for its high performance and durability.

Get Price

The layer crystallization process has the potential to produce the same milk fat fractions as can be obtained by the suspension crystallization process. That is, milk fat fractions with solid fat content melting profiles similar to those obtained by suspension fractionation can be

Get Price

Crystallization behavior and kinetics study of palm kernel oil (PKO) were investigated using differential scanning calorimetry (DSC) by controlling cooling and reheating rate within a certain range of temperature. The evolution of morphology and particle c...

Get Price

The present invention provide a continuous dry fractionation process comprising the successive step of: (a) providing a liquid glyceride oil having a temperature that is at least 5°C higher than the solidification onset point (SOP) of the glyceride oil, the SOP of the glyceride oil being the minimum temperature at which the glyceride oil has a N-value of 0%; (b) precooling the liquid

Get Price

Abstract: Laboratory-scale experiments were carried out to evaluate the influences of operational parameters on the melt crystallization efficiency for p-cresol purification.The optimal crystallization conditions were determined:dynamic pulsed aeration at 90 L·h-1 and the cooling rate of 0.6-0.8℃·min-1,followed by sweating at 0.2-0.3℃·min-1 for 40 min.Results also demonstrate that the

Get Price

For fat fractionation and phase change materials, emulsification can be applied as a tool to improve the fat crystallization process, and thus the product quality of the crystallized fat. Furthermore, the use of emulsification creates new application fields such as solid lipid nanoparticles in the area of fat crystallization.

Get Price

Fractionated coconut oil contains only the medium-chain triglycerides of coconut oil, making it a liquid at relatively low temperatures. It is a very stable oil. Fractionated coconut oil has indefinite shelf life and is a light, non-staining, non-greasy, colorless oil. It is great for use in massage, toiletries and soap.

Get Price

Crystallization behavior and kinetics study of palm kernel oil (PKO) were investigated using differential scanning calorimetry (DSC) by controlling cooling and reheating rate within a certain range of temperature. The evolution of morphology and particle counts was analyzed by focused beam reflectance measurement (FBRM) and particles video microscope (PVM) at the nucleation stage during

Get Price

Palm oil Wikipedia. After milling, various palm oil products are made using refining processes. First is fractionation, with crystallization and separation processes to obtain solid (), and liquid fractions.

Get Price