9.11.1 Vegetable Oil Processing 9.11.1.1 General1-5 The industry group producing fats and oils includes cottonseed oil mills, soybean oil mills, vegetable oil mills (other than corn, cottonseed, and soybean), and other mills. Wet corn mills are the primary producers of corn oil. Approximately 137 vegetable oil plants operate in the United States.

Electrocoagulation with aluminum electrodes was used to treat the vegetable oil refinery wastewater (VORW) in a batch reactor. The effects of operating parameters such as pH, current density, PAC (poly aluminum chloride) dosage and Na 2 SO 4 dosage on the removal of organics and COD removal efficiency have been investigated. It has been shown that the removal efficiency of COD increased with ...

Get Price

Treatment and reuse of wastes of a vegetable oil refinery Article in Resources Conservation and Recycling 37(2):101-117 · January 2003 with 1,134 Reads How we measure 'reads'

Get Price

In search of an efficient method for the revalorization of spent bleaching earth (SBE), a waste from vegetable oil refinery plant, three different solvent extraction strategies were adopted.

Get Price

Environmental, health, and safety guidelines for vegetable oil production and processing (English) Abstract. The environmental, health, and safety (EHS) guidelines are technical reference documents with general and industry-specific examples of good international industry practice (GIIP).

Get Price

High Efficiency Vegetable Oil Refinery Plant Edible Oil Refining Machine Cooking Oil Refining Plant , Find Complete Details about High Efficiency Vegetable Oil Refinery Plant Edible Oil Refining Machine Cooking Oil Refining Plant,Vegetable Oil Refinery Plant,Edible Oil Refining Machine,Cooking Oil Refining Plant from Supplier or Manufacturer-.

Get Price

High Efficiency Cooking Oil Refinery Plant Crude Peanut. China Environmental and High Efficiency Vegetable Oil Refinery, and other impurities The entire oil refining plant Pump crude oil into refining Online Chat Send Inquiry Product Categories

Get Price

With the start up of the Green Refinery, eni will be able to produce around 300,000 tonnes per year of green diesel already in 2014. The feedstock will initially be palm oil; in the second phase, also animal fats, used oil, oils from algae and various types of biological waste.

Get Price

confirm that the vegetable oil refinery wastewater has a varying high organic pollution load. The variation of contents of sulfates, phosphates and chlorides was also observed. Comparison of the Technological Wastewater and the Final Treated Wastewater Effluent The main pollution load in the technological waste-

Get Price

The EHS Guidelines for Vegetable Oil Production and Processing are applicable to facilities that textract and process oils and fats from a variety of seeds, grains, and nuts; these include canola, castor, cottonseed, mustard, olive, palm, palm-kernel, peanut (groundnut), rapeseed, safflower, sesame, soybean, and sunflower.

Get Price

Energy and exergy analysis was conducted for a vegetable oil refinery in the Southwest of Nigeria. The plant, powered by two boilers and a 500 kVA generator, refines 100 tonnes of crude palm kernel oil (CPKO) into edible vegetable oil per day. The production system consists of four main group operations: neutralizer, bleacher, filter, and deodourizer.

Get Price

Treatment and reuse of wastes of a vegetable oil refinery Article in Resources Conservation and Recycling 37(2):101-117 · January 2003 with 1,105 Reads How we measure 'reads'

Get Price

A comparative assessment of resource efficiency Another key difference is the share of oil sands in crude feed to US refineries since GHG intensities of oil sands crude are typically higher A consequence of this lower share of hydrogen from the SMR results in a higher overall energy efficiency for the High API/High HP refinery

Get Price

1-7-2002· Today, however, environmental concerns may reverse these trends, making energy-saving investments more attractive as fuels become more expensive. Energy efficiency The refining industry as a whole can be classified as energy inefficient. The worldwide average refinery energy consumption is about 95 per cent higher than KBC’s best practice target.

Get Price

Automatic control system assures high efficiency oil refinery The application of advanced automatic control system in large oil refining plant provides the most secured, reliable production in entire workshop and monitors the operation status by controlling the computer terminals. Low production cost and high purity refined oil.

Get Price

9.11.1 Vegetable Oil Processing 9.11.1.1 General1-5 The industry group producing fats and oils includes cottonseed oil mills, soybean oil mills, vegetable oil mills (other than corn, cottonseed, and soybean), and other mills. Wet corn mills are the primary producers of corn oil. Approximately 137 vegetable oil plants operate in the United States.

Get Price

High Efficiency And Profit Large Capacity Oil Refinery Plant For Car,Find Complete Details about High Efficiency And Profit Large Capacity Oil Refinery Plant For Car,Oil Refinery Plant.,Large Capacity Oil Refinery Plant,Oil Refinery Plant For Car Engine from Waste Management Supplier or Manufacturer-.

Get Price

Environmental, health, and safety guidelines for vegetable oil production and processing (English) Abstract. The environmental, health, and safety (EHS) guidelines are technical reference documents with general and industry-specific examples of good international industry practice (GIIP).

Get Price

European Refining Outlook to 2030: Technical & Economic Challenges 2005 High gasoline High diesel Demand Simple refinery Complex refinery Yield (% on crude oil) LPG Naphtha Gasoline Kero/Jet Gasoil/Diesel Heavy fuel oil. European Refining Outlook 2030 vegetable oil BTL = biomass to

Get Price

The oil normally becomes cloudy in 5–6h but with proper dewaxing the oil remains clear after 24h of storage at 0˚C. The following steps are used to dewax sunflower oil: Crude oil is refined and bleached to low phosphorus (<1ppm) and low moisture content (<0.1%). The oil is heated to 55˚C to make sure the oil

Get Price

Suppliers of soybean oil extraction machines for sale _Factory price vegetable oil machine. Rice experience with turnkey soybean oil extraction machines. Doing owns rice experience of design, manufacturing and installation of soybean oil extraction plant with guaranteed high efficiency, high profit and reliable extraction process. Come

Get Price

Challenges and Solutions in an Upstream and Downstream Oil and Gas Operation The oil and gas industry has lots of influences in the world today. Oil and gas have direct influence on every other commodity in the market. Therefore it is critical to identify risk and solutions through technological innovation to maintain global economic balance

Get Price

China Oil Refinery Plant manufacturers Select 2020 high quality Oil Refinery Plant products in best price from certified Chinese Oil Pump manufacturers, Oil Treatment suppliers, wholesalers and factory on Made-in-China

Get Price

Even in regions with low energy costs, maximizing energy efficiency is high on the agenda to reduce emissions and the refinery environmental footprint. With highly efficient Alfa Laval heat exchangers, such as our Packinox, Compabloc and spiral heat exchangers, you can maximize energy efficiency with minimal investment and plot space required.

Get Price

1-11-2016· November 2016 Columns Refining: High-impact challenges in today’s global refining market. To stay competitive and thrive in today’s uncertain and volatile energy market that is characterized by major shifts in supply and demand dynamics, refiners must find ways to increase operational efficiencies, maximize productivity and produce refined products at lower costs.

Get Price

1) New technologies for the production of high performance elastomer. Companies are exploring new solutions in the fields of elastomers for car tires in line with the strict European standards. One of the these innovative solutions consists on the use of oils of vegetable origin, with low environmental impact and high performance.

Get Price

Polish Journal of Environmental Studies Vol. 10, No. 3 (2001), 141-147 This paper presents results of investigations on physicochemical treatment of vegetable oil refinery wastewater (VORW), confirm that the vegetable oil refinery wastewater has a varying high organic pollution load. The variation of

Get Price

Chinese Edible Oil Refinery Plants Operate with Vahterus’s Heat Exchangers. oil spillage into the operating environment raises environmental and safety concerns. The PSHE has the advantage of combining the high-heat transfer efficiency of a plate-type

Get Price

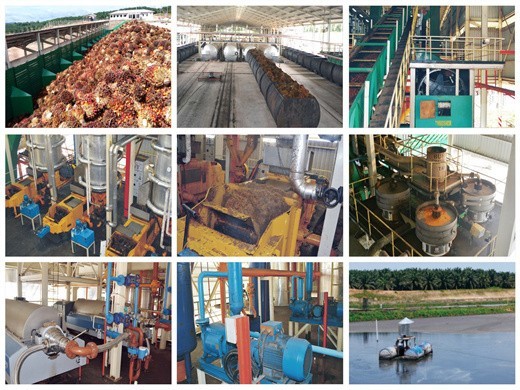

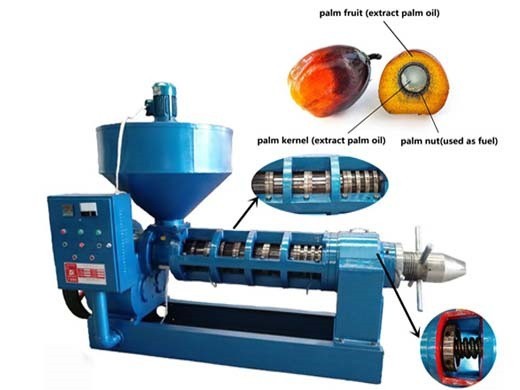

Palm oil is not only the highest yielding cheap vegetable oil on the earth but also a safe raw material for edible oils and daily chemicals, Each ton of palm oil produced emits about 20 tons of high-concentration organic wastewater. friendly environment, economic efficiency and has the following technical benefits:

Get Price

Construction of a high-efficiency solar farm. In late 2017, a solar farm equipped with high-efficiency cells produced by the Group’s affiliate SunPower came on stream at the La Mède facility. It has a production capacity of 8 megawatts, enough to meet the energy needs of a city of 13,000 people.

Get Price

The palm oil refinery plant project uses a physical refining method to process palm oil, which has low production cost, high efficiency, and simple production process.5tpd palm oil physical refinery plant not only used to refine palm oil and palm kernel oil, but also used to refine soybean oil, peanut oil, sunflower oil, cottonseed oil and

Get Price

DHA is an important unsaturated acid. At present, DHA algae oil in the refining process is still continue to use traditional vegetable oil refining process of degumming, alkali refining, bleaching and deodorization, the deodorization is a very important process, under the condition of high temperature and high vacuum ,through steam distillation process to remove the impurity and deodorization.

Get Price

UNESCO EOLSS SAMPLE CHAPTERS PETROLEUM ENGINEERING DOWNSTREAM Environmental Impacts Of The Oil Industry Jacqueline Barboza Mariano, Emilio Lèbre La Rovere ©Encyclopedia of Life Support Systems (EOLSS) • Thermal pollution due to discharge of effluents with temperatures higher than

Get Price

Resources Institute‟s (TERI) attempt to study the Vegetable Oil Refinery energy consumption trends and energy efficiency improvement opportunities in the Vegetable Oil Refinery in India.

Get Price

Environmental Impacts of Production of Biodiesel and Its Use in Transportation Sector. By Sippy K. Chauhan and Anuradha Shukla. which yields starch that is fermented into bioethanol, or sunflower seeds, which are pressed to yield vegetable oil that can be used in High efficiency Diesel Particulate Filter (DPF) remove particulate

Get Price

Chapter 4 Environmental Progress . WORKING TOGETHER, WE CAN PROTECT OUR ENVIRONMENT . WOOD RIVER REFINERY . Roxana, Illinois . research to convert cooking oil, tallow or vegetable oil into high-quality diesel fuel with a low-carbon footprint.

Get Price

Eni has opened its latest biorefinery in Europe at Gela. Launched in August 2025, the plant has a processing capacity of up to 750 000 tpy and will be able to treat increasing quantities of used vegetable oil, animal fat, algae and by-products to produce high-quality biofuels.

Get Price