Asphaltene-removal technolgy yields eco-friendly refinery by-products ... as dry granulates in heavy crude oils and petroleum residueontinue to provide refiners with a cost-effective and ...

Advanced Process Crude Oil Petroleum Distillation Refinery Plant Equipment , Find Complete Details about Advanced Process Crude Oil Petroleum Distillation Refinery Plant Equipment,Crude Oil Refinery Equipment,Petroleum Refinery Plant,Crude Oil Distillation Plant from Machine Oil Purifier Supplier or Manufacturer-.

Get Price

Petroleum refining industry is entering into the significant era of reformation due to the depletion of light petroleum and an increase in heavy or extra heavy crude oil production.

Get Price

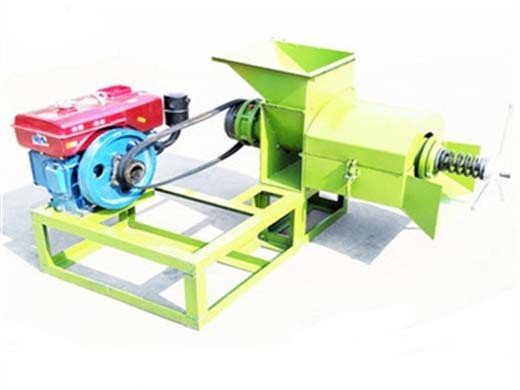

Waste Oil Recycling Equipment. Brand: Jinpeng Packaging: In containers Supply Ability: 30sets per month Min. Order: 1 Set/Sets Waste Oil Recycling Equipment 1 Distillation Machine Description Waste oil distillation plant is designed to recycle waste oil crude oil waste engine oil pyrolysis oil the output oil is diesel which could be used for the farm machine tractors trucks and ship engine etc ...

Get Price

The Mostorod refinery project promises to generate several economic benefits in a short term and environmental and social advantages in a long run. ERC Refining Processes. The CORC refinery processes crude oil to produce numerous products, 67% of which in-clude what is known as atmospheric residue.

Get Price

The newest technology continuous modular crude oil petrochemical refinery/distillation plant/refining machine Product Description Crude petroleum refining production of gasoline, kerosene, diesel, heavy oil and natural gas is the main supplier of major energy.

Get Price

Petroleum products result from chemical processes that change the molecular nature of selected portions of crude oil; in other words, they are the products of refining. A refinery is essentially a group of manufacturing plants that varies in number with the variety of products produced in order to give a balanced operation.

Get Price

Comparing a startup refinery with an older refinery The capital-related process cost accounts for 476% of the total process cost (Table 2). Thus, using old units to reduce the overall capital-related process cost can raise the profit margin per ton of crude oil refined appreciably in an older refinery.

Get Price

Libya yo-yoing oil industry soon will enter a fourth post-revolution phase promising growth in oil production and related support for an essential condition: stability. Bob Tippee Dec 3rd, 2025

Get Price

An environmentally friendly oil industry . Government regulation, environmental concerns, and alternative fuels could shift the economic balance toward new petroleum refineries that solve problems right from the start. Daman Studio. Recently, representatives from ExxonMobil urged the public to vote for a strong economy in their ampaign 2000 Briefing. "Energy is a fundamental part of

Get Price

Advanced Process Crude Oil Petroleum Distillation Refinery Plant Equipment,Find Complete Details about Advanced Process Crude Oil Petroleum Distillation Refinery Plant Equipment,Crude Oil Refinery Equipment,Petroleum Refinery Plant,Crude Oil Distillation Plant from Machine Oil Purifier Supplier or Manufacturer-.

Get Price

Environmental smsll mini crude oil petroleum refinery distillation plant cost Product Description , adopts The most advanced technology of China University of Petroleum Design Institute, export of crude oil refining equipment always walk in the forefront of the refining industry.

Get Price

Comments Off on PRL An environment friendly refinery; Pakistan Refinery Limited (PRL) was built and commissioned in October 1962 at Karachi in alliance with major foreign oil companies like Burmah Oil California, Texas Oil Corporation, Shell Petroleum Corporation and ESSO Standard Eastern Inc. PRL is a hydro skimming refinery with a crude processing capacity of 50,000 barrels per operating

Get Price

The Mini refinery unit can be applied to Crude oil, black engine oil, plastic oil and shale oil, to produce Petrol, diesel and kerosene, as major products. The Mini Units will process a crude oil under the atmospheric distillation unit/vacuum distillation unit and catalytic cracking unit, heating with fuel oil or gas to 410 鈩? The refined

Get Price

Petroleum refining Petroleum refining Refinery plant and facilities: Each petroleum refinery is uniquely configured to process a specific raw material into a desired slate of products. In order to determine which configuration is most economical, engineers and planners survey the local market for petroleum products and assess the available raw materials. Since about half the product of

Get Price

20.09.2013· Crude oil can be separated into various fractions by the process called fractional distillation. Separation into fractions is based on differences in boiling points of the hydrocarbon components

Get Price

The crude oil distillation unit. The crude oil distillation unit (CDU) is the first processing unit in virtually all petroleum refineries. The CDU distills the incoming crude oil into various fractions of different boiling ranges, each of which are then processed further in the other refinery processing units.

Get Price

The refinery oil conversion ratio amounted to 74.4% as of the beginning of 2016 with the yield of light oil products amounting to 71.87%. The total volume of processed petroleum raw materials amounted to 9.2 million tonnes in 2015, including 8.6 million tonnes of crude oil. The TANECO Complex ranks No. one among refineries of the Russian

Get Price

26.05.2017· like our Facebook Page https://facebook/piping.official/ Do like, Share, Comment & Subscribe you can also watch my other videos, links are given belo...

Get Price

Diagram of Fractional Distillation of Crude Oil Original diagram drawn by Theresa knott, adapted by Keir Chapman for Earth Site Encyclopedia An oil refinery or petroleum refinery is a modern process plant where raw petroleum is handled and refined into additional handy features for example petroleum naphtha, gas, diesel fuel, black-top []

Get Price

Oil Refinery: An industrial plant that refines crude oil into petroleum products such as diesel, gasoline and heating oils. Oil refineries essentially serve as the second stage in the production

Get Price

How crude oil is refined into petroleum products. Petroleum refineries change crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocks for making chemicals.. Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products.

Get Price

The refinery oil conversion ratio amounted to 74.4% as of the beginning of 2016 with the yield of light oil products amounting to 71.87%. The total volume of processed petroleum raw materials amounted to 9.2 million tonnes in 2015, including 8.6 million tonnes of crude oil. The TANECO Complex ranks No. one among refineries of the Russian

Get Price

Business listings of Oil Refinery Plant, Biodiesel Refinery Plant manufacturers, suppliers and exporters in Chennai, Tamil Nadu along with their contact details & address. Find here Oil Refinery Plant, Biodiesel Refinery Plant, suppliers, manufacturers, wholesalers, traders with Oil Refinery Plant

Get Price

Oil Refinery Operations The United States is home to thousands of oil refineries, all of which need experts to run their operations. Oil refinery operators are highly paid and enjoy a stable work environment, and there's an ongoing need for entry-level personnel.

Get Price

High quality standard petroleum crude oil vacuum distillation unit plant machine, US $ 200000 10000000 / Set, New, 50L/min -300L/min, Henan, China.Source from . on.

Get Price

Petroleum refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as oil refineries) to transform crude oil into useful products such as liquefied petroleum gas (LPG), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils.

Get Price

The objective of this study is to analyze and describe the strategies and facilities to minimize environmental pollution caused by the existing single crude oil refining plant Eastern Refinery

Get Price

A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. A refinery's capacity refers to the maximum amount of crude oil designed to flow into the distillation unit of a refinery, also known as the crude unit.. The diagram above presents a stylized version of the distillation process.

Get Price

PCK is a no-residue refinery. The last remaining crude oil components that cannot be used are converted into electrical energy in our combined heat and power plant. Half the energy we generate is fed into the state's power grid. This modern power plant also supplies district heating to the city of Schwedt. The power plant boasts high energy

Get Price

ab0cd Sub-sectoral Environmental and Social Guidelines: Petroleum Refineries Petroleum Refineries Sub-sectoral Environmental Guidelines Page 1 March 2011 PROCESS DESCRIPTION Petroleum refining is the physical, thermal and chemical separation of crude oil into its major distillation fractions which are then further

Get Price

Petroleum refining Petroleum refining Vacuum distillation: The principles of vacuum distillation resemble those of fractional distillation (commonly called atmospheric distillation to distinguish it from the vacuum method), except that larger-diameter columns are used to maintain comparable vapour velocities at reduced operating pressures.

Get Price

Micro Used Crude Oil Refinery For Sale Xinxiang Huayin Plant. Micro used crude oil refinery for sale Xinxiang Huayin Plant. The pyrolysis oil desulfurization to diesel plant in machine oil purifier for industrial is produced by the most advanced technology,It is the most convenient and economic & environmental friendly way to refining the

Get Price

Since S-OIL first began the commercial operation of its 1st crude oil distillation unit with a capacity of 90,000 barrels/day in 1980, it expanded facilities on two occasions. S-OIL is now ideally positioned as a highly competitive oil refining company with three crude distillation units with 669,000 barrels/day of

Get Price

As a complex refinery, the refining process involves various steps that take place in the crude distillation units, the upgrading units, and the quality improvement units, that make Thaioil becomes one of Asia-Pacific leading producers of high quality petroleum products. It also allows for flexibility in using raw materials or crude oil

Get Price

The objective of this study is to analyze and describe the strategies and facilities to minimize environmental pollution caused by the existing single crude oil refining plant Eastern Refinery

Get Price

The heaviest product is heavy oil. The Slagentangen refinery produces of course sulphur free diesel (less than 10 ppm sulphur), which is a prerequisite for modern, environmentally friendly cars with catalyst treatment of exhaust gases. In 2007, the refinery installed a plant for blending of biodiesel. It supplies diesel with up to 7 per cent

Get Price

The waste oil distillation machine can run under normal pressure and vacuum pressure conditions. Fully sealed distillation reactor and distillation tower, avoid gas leakage, ensure no pollution, automatic feeding and discharging system, easy operation and can greatly save manpower. Working process of waste oil distillation plant: First, crude oil / waste oil / pyrolysis oil / waste engine oil

Get Price