Layout for Oil Palm Dry Fractionation Method . Crystallization Technique. The RBDPO Feed Oil is pumped to the Crystallizer. The fractionation system is batch type made up of vertical cylindrical vessel full of thermo-regulated water which is fitted with a mechanical agitator which rotates at the slow speed.

Hydrogenation is a reaction involving the use of a catalyst, usually nickel, and is also an exothermic reaction, thus vegetable oil hydrogenation is an important process in oil modification. Oil Fractionation. In the field of edible oil processing plant, fractionation almost always refers to the mechanical separation of the liquid from the ...

Get Price

We are offering international quality standard Fractionation Process for Edible Oil for oil mills all over the world. High end technology and premium raw materials are used in fabricating high performance and durable of our Fractionation machinery for our clients.

Get Price

In edible oil processing, a fractionation process consists of a controlled cooling of the oil, thereby inducing a partial, or ‘fractional’, crystallization. The remaining liquid (olein) is then separated from the solid fraction (stearin) by means of a filtration or centrifugation.

Get Price

Frequently asked questions about vegetable oil processing technology, edible oil refining process, methods, steps, technology, and the detailed introduction based on engineers' explaination.

Get Price

Crude oil fractionation process started in the early twentieth century, widely applyed in industrial production. There're 3 types of crude oil fractionation process, dry fractionation, solvent fractionation and surface active aent fractionation.

Get Price

Oil Fractionation Process technology adopts advanced palm oil processing technology of controlled cooling, crystallization, filtration and separation technology, obtaining palm oil with different melting points, like 33℃, 24℃, 18℃, 14 ℃,12℃,10℃,8℃,etc.

Get Price

Edible Oil Technology is a very vast topic which includes the range of industrial processes that start with the seed crushing and production of oils along with the secondary stage as the processing of those oils.

Get Price

Edible Oil Process,Vegetable Oil Plant,Grain Process Plant,Oil Press Machinery manufacture in china,Fueled by innovation is one of the leading name in undertaking Turnkey Projects for for Solvent Extraction Plant, Tea Extraction Plant, Spice Extraction Plant, Acid Oil Plant, Feed Plant, Feed Milling Plant, Dry Fractionation Plant, Oil Mill

Get Price

Layout for Oil Palm Dry Fractionation Method . Crystallization Technique. The RBDPO Feed Oil is pumped to the Crystallizer. The fractionation system is batch type made up of vertical cylindrical vessel full of thermo-regulated water which is fitted with a

Get Price

Being a more expensive process, it is less common than dry fractionation and only comes into the picture when a very high added value of (at least one of) the resulting fractions makes up for the high cost. Dry Fractionation: through batch crystallization of oil without using additives by controlled cooling and subsequent continuous filtration.

Get Price

Hydrogenation is a reaction involving the use of a catalyst, usually nickel, and is also an exothermic reaction, thus vegetable oil hydrogenation is an important process in oil modification. Oil Fractionation. In the field of edible oil processing plant, fractionation

Get Price

In edible oil processing, a fractionation process consists of a controlled cooling of the oil, thereby inducing a partial, or ‘fractional’, crystallization. The remaining liquid (olein) is then separated from the solid fraction (stearin) by means of a filtration or centrifugation.

Get Price

We are offering international quality standard Fractionation Process for Edible Oil for oil mills all over the world. High end technology and premium raw materials are used in fabricating high performance and durable of our Fractionation machinery for our clients.

Get Price

Dewaxing may be the fifth process considered for the edible oil refining. It is not a compulsory process and it is not required for every type of oil. Dewaxing is performed only for high wax containing oils such as Sunflower Oil, Rice Bran Oil, Corn Oil etc.

Get Price

Edible Oil Technology is a very vast topic which includes the range of industrial processes that start with the seed crushing and production of oils along with the secondary stage as the processing of those oils.

Get Price

Neutralization or simply Neutralizing is the second process in the vegetable oil refining which commences after degumming completion. The feedstock is taken into the Neutralizers where the heating temperature range is kept at 55 C to 70 C depending on the quality of crude oil. The oil is under constant agitation to maintain the uniformity.

Get Price

Deodorization is the final stage of Oil refining. It removes odoriferous matter, free fatty acids and other unwanted components to produce bland and stable oil.

Get Price

We are offering international quality standard Fractionation Process for Edible Oil for oil mills all over the world. High end technology and premium raw materials are used in fabricating high performance and durable of our Fractionation machinery for our clients.

Get Price

Vegetable oil extraction machine manufacturer supplies high quality mature technology cooking oil processing machine and edible oil refinery plant with factory price,which can produce soybean oil, sunflower oil, groundnut oil, palm oil, etc.

Get Price

Oil is a compound of many kinds of glycerol triester. Oil fractionation is the process of separating oil into different glycerol triester at certain temperatures. Oil fractionation is a physical process, with no expensive or hazardous chemical additives, no chemical reaction, no loss and waste water. Crude Oil fractionation is applied in processing palm oil, sunflower oil, cottonseed oil, rice

Get Price

Refined palm oil should go through fractionation process to separate solid phases (Stearine) and liquid phases (Olein). It is achieved by thermo-mechanical means. Fractionation can greatly maximize the value of products.The typical fractionation process of palm oil mill is controlled cooling, crystallization, and filtering. The liquid fraction, which is also known as olein is getting more and

Get Price

In batch oil refinery process or cooking oil refinery process, a measured quantity of oils is processed in sequence of neutralizing, bleaching & deodorizing. Crude oil obtained from expellers or solvent extraction plant contains foreign impurities such as mucilage, gums, coloured &

Get Price

Dry Fractionation Plant : Process Description Dry Fractionation is a process to separate vegetable oils such as palm oil into two fractions, Olein and Stearin, by the crystallization properties of the oils. A typical dry fractionation plant consists of

Get Price

Hydrogenation is a reaction involving the use of a catalyst, usually nickel, and is also an exothermic reaction, thus vegetable oil hydrogenation is an important process in oil modification. Oil Fractionation. In the field of edible oil processing plant, fractionation almost always refers to the mechanical separation of the liquid from the

Get Price

Oil Modification Hydrogenation Plants, Fractionation. Hydrogenation Hydrogenation is an oils and fats modification process.It is mainly used on vegetable oils like soya, rape, cotton or sunflower to increase their oxidative stability and to improve their melting properties by reducing their degree of unsaturation.

Get Price

Practical Guide to Vegetable Oil Processing, Second Edition, includes an up-to-date summary of the basic principles of edible oil refining, processing, and deodorizing, serving as a hands-on training manual for chemists, engineers, and managers new to the industry. The 15-chapter book includes current information on the bleaching of green oils and coconut oil

Get Price

Oil Modification Hydrogenation Plants, Fractionation. Hydrogenation Hydrogenation is an oils and fats modification process.It is mainly used on vegetable oils like soya, rape, cotton or sunflower to increase their oxidative stability and to improve their melting properties by reducing their degree of unsaturation.

Get Price

Practical Guide to Vegetable Oil Processing, Second Edition, includes an up-to-date summary of the basic principles of edible oil refining, processing, and deodorizing, serving as a hands-on training manual for chemists, engineers, and managers new to the industry. The 15-chapter book includes current information on the bleaching of green oils and coconut oil, quality requirements for frying

Get Price

Process Description of Vegetable Oil Refining is as follows. Water Degumming : Water Degumming is first step in the Edible Oil Refinery Process.Oils contains Hydratable Phosphatide which absorb the water, that Hydratable Phosphatides are oil- insoluble

Get Price

12-9-2015· Edible Oil Refining Workshop 1-10tpd palm oil fractionation plant, COOKING OIL REFINERY, EDIBLE OIL REFINERY, VEGETABLE OIL REFINERY Duration: 1:42.

Get Price

21-11-2017· 1-10tpd batch type edible oil refinery plant,small scale cooking oil refining machine video Duration: 7:00. Wendy Wang 25,904 views

Get Price

Besides, dewaxing process is carried out for rice bran oil and sunflower oil, in order to separate the wax from final range. In batch type vegetable Oil Refinery plant, processes are carried out by deodorizing, bleaching and neutralizing of certain quantity of oil. As the batch process

Get Price

Edible oil refinery plant and edible oil refining process . Edible oil refining is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils.

Get Price

Edible Oil Process,Vegetable Oil Plant,Grain Process Plant,Oil Press Machinery manufacture in china,Fueled by innovation is one of the leading name in undertaking Turnkey Projects for for Solvent Extraction Plant, Tea Extraction Plant, Spice Extraction Plant, Acid Oil Plant, Feed Plant, Feed Milling Plant, Dry Fractionation Plant, Oil Mill

Get Price

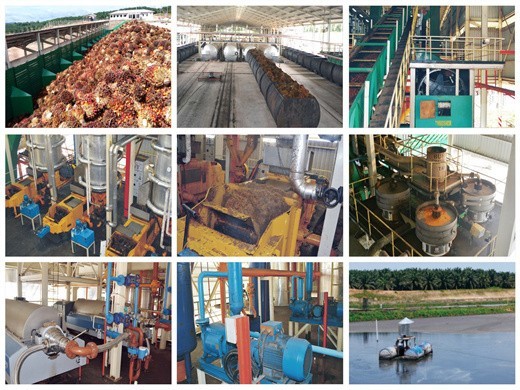

Innovative thinking is essential to meeting the future demands of vegetable oil producers. Take palm oil, for example, the world’s most widely used vegetable oil and a business with razor-thin margins. Here, the challenge is to ensure 24/7 production, extracting as much from the palm fruit as possible.

Get Price

Mechanical Pressing Process(Screw Pressing Process) Oil Expeller or called Oil Screw Press is the key equipment of oil screw pressing process. AGICO can professionally produce mechanical oil pressing machines for different requirements, the production

Get Price