Edible Oil Refinery consists of Soyabean Oil Refinery Plant, Coconut Oil Refinery Plant and Sunflower Oil Refinery Plant. We also manufacture Small Scale Mini Oil Refinery and Batch Type Oil Refinery Plants from India.

Vegetable Oil Refining / Refinery Plant What is Refining? The crude oil obtained either from expellers or solvent extraction plant contains impurities, which must be removed to make the oil edible, more palatable and stable against rancidity upon storage.

Get Price

Edible Oil & Fat Refining . 2 . IPS maintenance . Engineering . General . Excellent experience gained over the last years on Edible oil refining and oleochemical plants further reinforces our commitment to offer innovative and eco sustainable solutions for both edible and inedible oil processing plants. Our ability to design in this field is represented in the following pages which show our ...

Get Price

Refining crude oil into edible oil requires deep process knowledge—from degumming, neutralization and dewaxing through to bleaching, deodorizing and GE and 3-MCPD mitigation. Edible oil producers worldwide rely on Alfa Laval know-how to remove impurities and volatile components and optimize refining processes. Count on us to ensure optimal ...

Get Price

VEOS also markets the co-products generated from the refining processes of vegetable oils. Identity Preserved oils and their refined co-products (derived from expeller & hexane solvent plants) are also brokered by VEOS in effort to meet the growing demand within Identity Preserved (Non-GMO, Organic, High-oleic) markets.

Get Price

We provide Edible Oil and Vegetable Refining plants and solutions to achieve optimum efficiency. Our refining plants are designed with quality in mind and manufactured at our own Pune based factory. Our manufacturing unit is ISO certified 9001-2015 and CRISIL rated.

Get Price

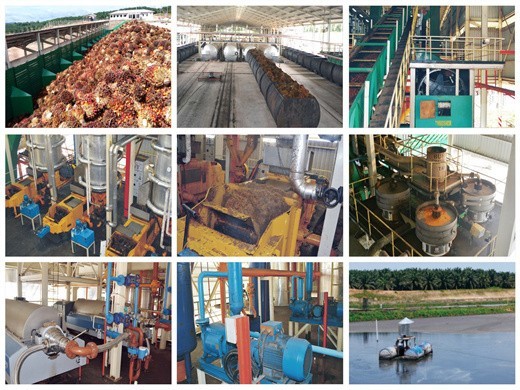

Edible oil press extraction plant is characteristic of high oil yeild and obvious economic benefits. See more . Offer turnkey solutions for palm oil refinery process, including physical refining and chemical refining of palm oil. Plant layout design, machinery manufacturing, onsite debugging and installing. Oil Refinery Palm Oil Layout Design Scale Medium Plants Projects Weighing Scale Log ...

Get Price

Energy and exergy studies of refining crude palm kennel oil into edible vegetable oil were conducted in a factory located in the southwestern Nigeria. The energy require-ment and exergy inefficiency for processing 100 tonnes per day of edible vegetable oil from palm kernel oil was estimated. The plant operates on a 3-shift of 8-working

Get Price

300tpd high efficiency oil refinery plant in mauritania, 300 TPD EDIBLE OIL REFINERY FOR SALE - Used Process Plants, Plant # 299 300 TPD EDIBLE OIL REFINERY FOR

Get Price

Processing Plant . Edible Oil & Fat Refining . 2 . IPS maintenance. Engineering . of clay for each vegetable oil. Concerning yield, the oil retention, depends on type of oil, higher levels of efficiency

Get Price

High efficiency crude oil refinery plant to produce refined edible oil Company Information Doing company is a professional manufacture of vegetable oil refinery machine, our company provides

Get Price

Edible Oil Refining Plants; Vegetable Oil Refinery; Bleaching Plants; Deodorization Plants; Winterization and Dewaxing Units; Crude Oil Processing Machinery; Oil Extraction and Milling Plants; The entire range of machinery is manufactured using latest technology that ensures optimal durability and efficiency

Get Price

Typically, the edible oil refining plant can be divided into three main types: batch oil refining, semi-continuous refining and continuous refining. Choosing which type for your edible oil refining line should assess the capacity, the purpose of final refined oils and detailed refining

Get Price

These Physical Refining Plant are designed to process different vegetable oils such as sunflower, Rice Bran, Mustard, Soya, Cotton Seed, Palm, Palm Kernel or corn oil.Basic process involves in Vegetable Oil Refineries some of the following or all the process steps depending on the oil being processed and whether the process selected is chemical refining or Physical refining.

Get Price

High efficiency cooking oil machine for sale_cooking oilHow much is the vegetable oil refinery plant investment cost? The introduction of small scale palm oil extraction and refining process How to

Get Price

The unique designed crude palm oil refining technology ensures high efficiency palm oil refining machine with less activity addition and low residual oil. Batch type palm oil refining machine with capacity 1-10tpd. Our developed palm oil refining machine has unique skill, stable performance, high

Get Price

Edible Oil Processing. Marine Oils and to the reduction of colour of the oil due to the breakdown of the remaining carotenes at high temperature. The efficiency of deodorization is a function of M.V. and Graciani Constante, E. Changes in olive oil components during deodorization and/or physical refining at the pilot plant scale using

Get Price

Practical Guide to Vegetable Oil Processing, Second Edition, includes an up-to-date summary of the basic principles of edible oil refining, processing, and deodorizing, serving as a hands-on training manual for chemists, engineers, and managers new to the industry.

Get Price

Edible Oil Refinery Equipment,Vegetable Oil Refining Plant. We provide high efficiency edible oil refining processing machines,oil refinery plant equipment to obtain high quality vegetable refined oil.Find Best Supplier or Manufacturer Htoilmachine.

Get Price

Energy and exergy studies of refining crude palm kennel oil into edible vegetable oil were conducted in a factory located in the southwestern Nigeria. The energy require-ment and exergy inefficiency for processing 100 tonnes per day of edible vegetable oil from palm kernel oil was estimated. The plant operates on a 3-shift of 8-working

Get Price

High Efficiency Oil Refining Machine,Edible Oil Refinery Plant. The crude oil obtained by screw pressing and solvent extraction of oilseeds needs to be refined in edible oil refinery because there are still some impurities such as phospholipids, FFA, pigment, odor, etc. in the crude oil.

Get Price

Edible oil refinery plant and edible oil refining process. Edible oil refinery plant and edible oil refining process . Edible oil refining is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils.

Get Price

high efficiency edible oil refining from vegetable plants High Efficiency Oil Refining Machine,Edible Oil Refinery Plant. Edible oil refinery is necessary for edible oil milling palnt. With high degree of automation, our oil refining machine can refine about 20 kinds of oil, in a small production line or in Anand oil mill plants Indian

Get Price

High Efficiency Oil Refining Machine,Edible Oil Refinery Plant. With a high degree of automation, our oil refining machine can refine about 20 kinds of oil, in a small production line or in large oil plant. Main Oil Refining Process Steps. 1. Degumming: The purpose of Degumming Vegetable

Get Price

active in the manufacture of edible oil refining plants for over one century and now it is Some vegetable oils, mainly sunflowerseed oil and corn oil, so that the deodorization efficiency is very high; the oil is flowing through an obliged path (except in semi-continuous models)

Get Price

Edible oil extraction and refining is done from several plant matters which are considered to be good sources such as safflower, hemp, walnuts, coconuts, soybeans, oil palm kernels, peanuts, soy beans, sunflower, almonds, sesame seeds, canola and hazelnuts among others.

Get Price

Again our customers rewarded us with orders varying from 25 TPD to 200 TPD complete grassroot vegetable oil refining plants. In a short span of 2 years again we installed 8 plants upgrading each time to meet the ever changing technology needs of the industry.

Get Price

The edible oil refinery machine is necessary for edible oil milling plants. With a high degree of automation, our oil refining machine can refine about 20 kinds of oil, in a small production line or in large oil plant.

Get Price

Edible oil press extraction plant is characteristic of high oil yeild and obvious economic benefits. Our Vegetable Oil Refining Plant & edible oil refineries in India are built for continuous Longmix, Cost Of Production Process Engineering Edible Oil Oil Refinery Oil Industry Energy Efficiency

Get Price

Refining crude oil into edible oil requires deep process knowledge—from degumming, neutralization and dewaxing through to bleaching, deodorizing and GE and 3-MCPD mitigation. Edible oil producers worldwide rely on Alfa Laval know-how to remove impurities and volatile components and optimize refining

Get Price

Edible Oil Refining Case Study: Background . A world-leading company in the refining of vegetable oils (palm oil, soyabean oil, rapeseed oil, sunflower oil, among others) has contacted SACOME to design and manufacture a process plant for the thermal treating of 45.000 kg/h of different types of edible oils within the refining

Get Price

Edible oil refinery plant manufacturer supplies high quality edible oil refining, Sunflower Oil Refinery, Automatic Vegetable Oil Plants offered by Mitsun Engineering, Vadodara, Gujarat. With our efficiency and vast knowledge of the industry, we have come up with a wide array of Refinery Plant..

Get Price

Rapeseed Oil Expeller Crude Oil Refinery Plant/Vegetable. Vegetable Oil Refining Machine. 1T/D-100T/D oil refining equipment small crude oil refinery soybean oil refinery plant small small scale sunflower oil production plant,soybean,peanut, rapeseed seed expeller Refinery Oil processing machine: Place of Origin : Jinan, 5-800T/D sunflower,rapeseed,cotton,soybean edible oil refinery/crude palm

Get Price

New Developments Offer Significant Changes in Vegetable Oil Refining. it was proven that if an oil had a degumming efficiency of 93% or higher, Texas A&M University, October 9–13, 2011, “Latest Technologies in Edible Oil Refining and Biodiesel,” Walter Farr.

Get Price

Most edible oils are deodorized at high temperature (230-260°C), but there is a growing demand from oil processors to lower the heat load (residence time at higher temperature) during deodorization. This is especially required to minimize thermal degradation reactions (e.g. formation of trans fatty acids in soybean and canola oil, formation of glycidyl esters in palm oil).

Get Price