Palm Oil Fractionation Plant. Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0鈩?to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.

Palm oil fractionation goes through the control of palm oil cooling and crystallization to make separation of palm oil into low melting point liquid (soft fat) and high melting solid (sterin). Fractionation of palm oil can be divided into three fractions: stearin (palmstearine), soft fat (palmolein) and middle section (palmmidfraction).

Get Price

The crystallization process follows in the palm oil fractionation process. This process involves the removal of high-melting glycerides that would cause the liquid oils to become viscous and cloudy at room temperatures. There are three most important factors in palm oil fractionation process : time, agitation and temperature.

Get Price

Since palm oil machinery plays a important role in palm oil production, it necessary to buy and purchase high quality and reliable palm oil machinery for palm oil production, either for small or large scale palm oil production lines and mills.so choose the palm oil machinery manufacturers is very important.

Get Price

For further processing of palm oil,the palm oil refining process and palm oil fractionation process is necessary.The palm oil refining process can get rid of the harmful impurities and needless substance in the crude edible oil, getting standard edible oil by utilizing the physical methods and chemical processes.

Get Price

A unique technique of gravitational membrane filtration is adopted in palm oil fractionation that helps in better olein recovery on a sustained basis. Besides, a higher recovery by 1% to 8% is possible depending upon the cloud point from 10 to 6. The process of fractionation can be applied to: Cotton seed oil.

Get Price

Palm oil mill process of oil clarifying: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. Oil by centrifugal separation and through vacuum drying pumped into the

Get Price

You can according to your actural situation choose suitable palm oil machines to start your palm oil business in Africa. Palm oil extraction business, palm oil refining business and palm oil fractionation business. 1) Crude palm oil extraction machine: It is used to produce crude palm oil (CPO) from fresh palm fruit bunches.

Get Price

During palm oil refining process, there are three types palm oil refinery plant can be chosen. Third, you can choose the palm oil refining machine and process according to your budget, we can design and adjust specific palm oil refinery quotation according to your budget, and also ensures the quality of machine unchanged.

Get Price

After palm oil fractionation, palm oil will be clean after 5.5 hours in 0 degree Celsius, but it also can keep transparency and flowability in the refrigerator and improve the oil quality and appearance. Palm oil fractionation process chart: Working principle of palm oil fractionation:

Get Price

The crystallization process follows in the palm oil fractionation process. This process involves the removal of high-melting glycerides that would cause the liquid oils to become viscous and cloudy at room temperatures. There are three most important factors in palm oil fractionation process : time, agitation and temperature.

Get Price

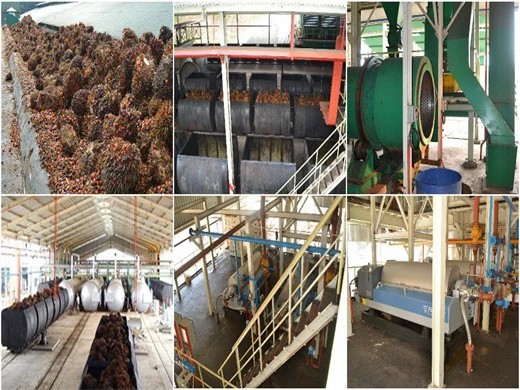

Sterilizer, Thresher, palm oil expeller, clarification equipment, palm nut polishing machine. Palm oil extraction process: Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit. This is the

Get Price

1-10tpd palm oil fractionation plant, machine to separate palm olein and palm stearin Wendy Wang Edible/Vegetable/Cooking Oil Deodorization Process - Duration: 8:56. DVC Process Technologies

Get Price

For Palm Oil Refinery Plant, Fractionation Process is required in which palm olein and palm stearin are separated by scientifically cooling the refined palm oil by chilling plant and then filtering the oil. For this purpose crystallizing vessel is used in which chilling pipe coils cool the oil for fractionation. Palm stearin crystals are formed

Get Price

Palm oil refining machine is mainly used to refine the crude oil comes from palm oil pressing workshop,after palm oil refining process, the oil can meet with first grade standard. Palm oil fractionation machine can obtain palm oil with different melting points.

Get Price

Palm Oil Processing Plant By-product Palm oil extraction does not end at the final product of edible palm oil. In the process of extracting and refining palm oil, by-products (which are what remains from the palm kernel after most of the oil...

Get Price

During palm oil refining process, there are three types palm oil refinery plant can be chosen. Third, you can choose the palm oil refining machine and process according to your budget, we can design and adjust specific palm oil refinery quotation according to your budget, and also ensures the quality of machine unchanged.

Get Price

The palm oil making process 1. Palm Fruits Reception 2. Sterilizing 3. Threshing 4. Digesting 5. Palm oil pressing 6. Clarification 7. Filtering, 8. Drying 9. Crude oil refining 10. Fractionation 11. Palm Kernel Recovery 12. Palm kernel oil extrac...

Get Price

The crystallization process follows in the palm oil fractionation process. This process involves the removal of high-melting glycerides that would cause the liquid oils to become viscous and cloudy at room temperatures. There are three most important factors in palm oil fractionation process : time, agitation and temperature.

Get Price

The whole palm oil production process consists of palm oil extraction & refining & fractionation process. Through palm oil extraction process, we can make palm fruit into red palm oil and palm nut with fibers. During palm oil extraction process, there are 3 types palm oil extraciton machine can be used, they are: (1) 300-500kg/h palm oil press

Get Price

How is Palm Oil Produced? - Fractionation. Skip navigation Sign in. LEARN HOW TO PROCESS PALM OIL 1-10tpd palm oil fractionation plant, machine to separate palm olein and palm

Get Price

Jamaican customer buy cooking oil refining machine from Company to refine palm oil. The manager of the Nigeria overseas office is officially on duty. Ugandan customers choose to purchase 30 tons/day palm oil refining and fractionation plant from DOING. Palm nut cracking and separating system is under installation in Nigeria

Get Price

Sterilizer, Thresher, palm oil expeller, clarification equipment, palm nut polishing machine. Palm oil extraction process: Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit. This is the

Get Price

After palm oil fractionation, palm oil will be clean after 5.5 hours in 0 degree Celsius, but it also can keep transparency and flowability in the refrigerator and improve the oil quality and appearance. Palm oil fractionation process chart: Working principle of palm oil fractionation:

Get Price

The crystallization process follows in the palm oil fractionation process. This process involves the removal of high-melting glycerides that would cause the liquid oils to become viscous and cloudy at room temperatures. There are three most important factors in palm oil fractionation process : time, agitation and temperature.

Get Price

Palm oil fractionation goes through the control of palm oil cooling and crystallization to make separation of palm oil into low melting point liquid (soft fat) and high melting solid (stearin). Fractionation of palm oil can be divided into three fractions: stearin (palm stearin), soft fat (palm olein) and middle section (palm mid fraction).

Get Price

Palm oil fractionation goes through the control of palm oil cooling and crystallization to make separation of palm oil into low melting point liquid (soft fat) and high melting solid (stearin). Crystallization and cooling have great impact on the palm oil fractionation process. Only good crystallization can ensure easy palm oil separation.

Get Price

But most of you must be wondering, what machines are needed to process palm fruits to consumable red oil? Here we would like to introduce for you in detail. We can supply palm oil extraction machine , palm oil refining machine and palm oil fractionation machine to help people start palm oil processing business

Get Price

We are a professional manufacturer of edible oil production line, where palm oil production line access to national patent level. Sterilization Station is an important section in palm oil processing line.So we need to know how to choose sterilizing tank and what type of sterilizing tank?. Both horizontal and vertical sterilizing tank are selectable for crude palm oil pressing plant Difference

Get Price

Refining of Crude Palm Oil: Part 1 In Part 1 of this lecture I explained the reasons for refining crude oil and described the differences between physical and chemical refining. Refining is

Get Price

Crude Palm Oil Mill Process Introduction:. 1.Weighing.Palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.Loading ramp.FFB after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank.

Get Price

After palm oil fractionation, palm oil will be clean after 5.5 hours in 0 degree Celsius, but it also can keep transparency and flowability in the refrigerator and improve the oil quality and appearance. Palm oil fractionation process chart: Working principle of palm oil fractionation:

Get Price

The crystallization process follows in the palm oil fractionation process. This process involves the removal of high-melting glycerides that would cause the liquid oils to become viscous and cloudy at room temperatures. There are three most important factors in palm oil fractionation process : time, agitation and temperature.

Get Price

After palm oil fractionation, palm oil will be clean after 5.5 hours in 0 degree Celsius, but it also can keep transparency and flowability in the refrigerator and improve the oil quality and appearance. Palm oil fractionation process chart: Working principle of palm oil fractionation:

Get Price

After palm oil refining process, you can get RBD palm oil. Even though RBD palm oil has been qualified, it can still be further processed into palm olein and palm stearin. If you want to get these two products, that means you need learn about palm oil fractionation process. RBD palm oil is separated into two layers: liquid layer and solid layer

Get Price

For further processing of palm oil,the palm oil refining process and palm oil fractionation process is necessary.The palm oil refining process can get rid of the harmful impurities and needless substance in the crude edible oil, getting standard edible oil by utilizing the physical methods and chemical processes. Palm oil refining machine

Get Price

Cooling efficiency and ordering ensure special crystal formation and filterability in palm oil fractionation.Under stirring and circulating water cooling state, according to set temperature difference between palm oil and cooling water, palm oil cooling time and control palm oil cooling process to form nuclei and slowly grow.

Get Price

Dry Fractionation Plant : Process Description Dry Fractionation is a process to separate vegetable oils such as palm oil into two fractions, Olein and Stearin, by the crystallization properties of the oils. A typical dry fractionation plant consists of Crystallization Section and Filtration Section.

Get Price