Four sectors of activity likely to produce specific effluent can be identified. oil production. Discharges include formation water extracted with crude oil and possible drilling sludge. Production water which has stayed in the tank has been in contact with oil, gas and rock. The qualitative and quantitative aspects of this water depends ...

Oil production and oil refinery waste treatment workshop and presentation (host of event: Safe Technologies Industrial Group). Find more http://zaobt.ru/.

Get Price

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sanitary sewer or to a surface water in the environment.. Most industries produce some wastewater.Recent trends have been to minimize such production or ...

Get Price

EPA promulgated the Petroleum Refining Effluent Guidelines and Standards (40 CFR Part 419) in 1974 and amended the regulations in 1975, 1977, 1982 and 1985.The regulations cover wastewater discharges at over 140 refineries across the country.

Get Price

An oil refinery or petroleum refinery is an industrial process plant where crude oil is transformed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene, liquefied petroleum gas, jet fuel and fuel oils. Petrochemicals feed stock like ethylene and propylene can also be produced directly by cracking crude oil without the need ...

Get Price

The review provides a detailed description on nature of effluent or wastewater produced from the oil refinery units, its discharge into the water bodies, toxicological effects of the effluent on ...

Get Price

.Study of refining wastewater pollution: case of vegetable oil refining industry Morocco M. Chatoui *¹, ... One of the important sources of pollutants is the oil refinery industry, being a significant water consumer and consequently a large wastewater producer. The treatment of vegetable oil refinery effluent has been a major issue of environmental concern in developing countries for the last ...

Get Price

The effluent treatment plant is treating 100% effluent generated by the refinery since its commissioning in December 2008 and consistently producing treated effluent (pH 6-8.5, Sulphide < 05.ppm, COD < 50 ppm, Oil & Grease < 5 ppm, Phenol < 0.35 ppm) meeting guarantee parameters for re-use for various applications mentioned earlier.

Get Price

oil industry production refinery - Industrial effluent . The buffer tank also has a role in maintaining the output temperature lower than 40°C. Indeed, refinery effluent can reach temperatures of between 40 and 60°C. These temperatures are suitable for the primary oil separation stage because high temperatures encourage water/oil to separate.

Get Price

The buffer tank also has a role in maintaining the output temperature lower than 40°C. Indeed, refinery effluent can reach temperatures of between 40 and 60°C. These temperatures are suitable for the primary oil separation stage because high temperatures encourage water/oil to separate. However, for the flotation and biological treatment

Get Price

Pemex Salina Cruz (Mexico) Until 1998, the largest Mexican oil refinery (330,000 barrels per day) was supplied with reservoir water (2,920 m 3 ·h –1) and its effluent was de-oiled and “treated” in non-aerated lagoons before being discharged to the sea.In order to conserve reservoir water for human consumption, Pemex initiated a program that became a three-phase BOT (Build, Operate

Get Price

effluent generated by ore refining units post-mine management industrial processes and effluent treatment oil industry production refinery Sichuan Petro, Chengdu, Chine refinery sludge and waste spent sodium hydroxide

Get Price

effluent generated by ore refining units post-mine management industrial processes and effluent treatment oil industry production refinery Sichuan Petro, Chengdu, Chine refinery sludge and waste spent sodium hydroxide

Get Price

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sanitary sewer or to a surface water in the environment.. Most industries produce some wastewater.Recent trends have been to minimize such production or

Get Price

The process at RSI Environmental allows for the highly-efficient disposal of contaminated soil . Our process is the only one to achieve the destruction of 99.9999% of contaminants for decontamination of hydrocarbon-impacted soils.. RSI handles the disposal of contaminated soils and hazardous industrial waste, the transportation as well as the treatment and recycling of hazardous waste.

Get Price

Treating oily wastewater sources is very broad, as the oil in the oil industry, oil refining, oil storage, transportation and petrochemical industries in the production process generate lot of oily wastewater (Ahmed et al., 2007, Machín-Ramírez et al., 2008, Chen and He, 2003). Oily wastewater pollution is mainly manifested in the following

Get Price

2015-03-16· Oil production and oil refinery waste treatment workshop and presentation (host of event: Safe Technologies Industrial Group). Find more zaobt.ru/.

Get Price

Amak process that is economical in overall life time cost is needed to make all of this feasible. Aquatech has experience working with these refinery effluent pollutants in the refinery market and offers the advanced petroleum wastewater treatment and recovery technology necessary for the refinery’s needs.

Get Price

Veolia also offers solutions for the management of hazardous waste, recycling by-products, industrial services, decommissioning and soil remediation. Veolia’s expertise in water, energy and waste management allows the Group to be the world leader in the provision of environmental services for the oil and gas industry.

Get Price

Oil-free waste water should never contain oil and hence, they may bypass waste treatment facilities and discharge directly into the refinery outfall line after decontamination through gravity separators or surge ponds to take care of for accidental contamination, (facilities should be provided for oil removal).

Get Price

Photo about Oil refinery petrochemical chemical industry fuel distillation of petrol industrial plant. Image of production, distillation, petroleum 20674317

Get Price

The aims of this review are: To identify the challenges facing the oil industry in achieving sustainable management of all wastes from inshore /offshore production facilities, and To compare and

Get Price

Turning crude oil into complex, useful products is the goal of the oil refinery industry. To make this happen, the crude oil is purified, distilled, and then converted into the needed products within a refinery. These large complexes, zoned as industrial entities, are a combination of pipeline systems, tank farms, and flare systems.

Get Price

the new challenges of the oil & gas industry (3.04 mb) The range of offers focuses on the needs of both upstream (exploration and production) and downstream customers (refining and petrochemicals) in the oil and gas industry.

Get Price

Industry Across Canada. Canada's oil and natural gas industry is active in 12 of 13 provinces and territories. Using goods and services from many regions, Canada's exploration and production of oil and natural gas is truly a national industry.

Get Price

Digital Technology in Oil Production and Refining. Digital technologies have been used in oil and gas exploration and production, as well as in refining, for many years. The amount of data harvested is growing exponentially and is now fundamentally transforming industrial processes and the way we work.

Get Price

2010-03-01· Bioassays using plants and cells cultures can be employed for assessing environmental safety and potential genotoxicity. In this study, the genotoxic potential of an oil refinery effluent was analyzed by means of micronucleus (MN) testing of Alium

Get Price

Article Neste Oil's oil refining uses its resources exceptionally efficiently and wisely. Hardly any waste is generated, and everything that can be recycled is recycled. This is why some of the functions are surprising, such as a type of precious metal production. The smart way in which resources are utilized can be seen in different parts of the refinery. Where can you find a major Finnish...

Get Price

Photo about Pipelines of a oil and gas refinery industrial plant. Image of equipment, dioxin, chemical 49835887

Get Price

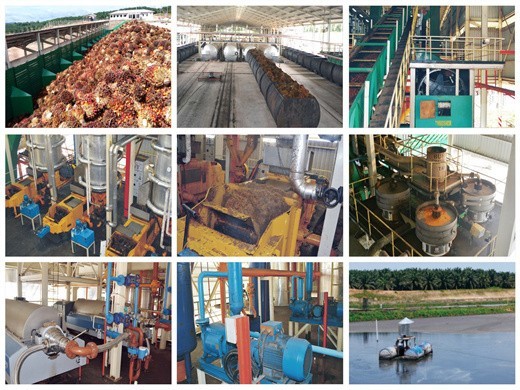

following Environmental Management Guidelines for the Palm Oil Mill Industry have been developed. These Guidelines deal with all aspects of the production of palm oil (except the refining of the oil) including liquid and solid by-products/residues and effluents/wastes and consider possible emissions to the atmosphere. These Guidelines promote

Get Price

An oil refinery is an industrial plant where crude oil is separated into a variety of different, useful substances through a variety of chemical separation steps. After extraction from the ground, processing at oil refineries is the second step in the production of different petroleum products.

Get Price

Photo about Pipelines of a oil and gas refinery industrial plant. Image of pernis, steel, dioxin 49836002

Get Price

Industry 4.0 and digitality enable the setup of new, more productive processes with enhanced visibility and management capabilities. To ensure these comprehensive benefits, Industry 4.0 is concerned with all processes of the company: production, procurement, sales and logistics, to mention a few.

Get Price

GEIR is the European Waste Oil Re-refining Industry Association1. GEIR member companies are active throughout Europe in supporting the collection of used oils and re-refining these back to valuable lubricant base oils. GEIR represents 80% of the waste oil re-refining industry in Europe.

Get Price

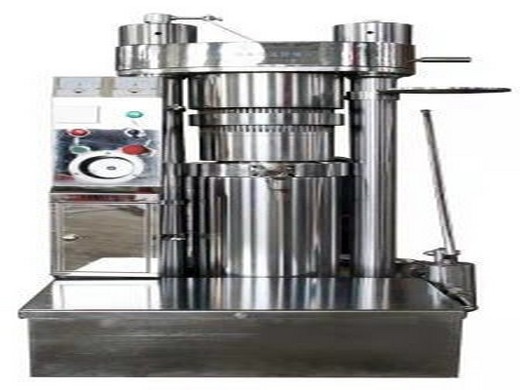

We offer 712 industrial crude oil refinery products. About 51% of these are oil pressers, 27% are machine oil purifier. A wide variety of industrial crude oil refinery options are available to you, such as automatic, semi-automatic.

Get Price

Crude Oil Production for Refinery Petroleum Industry from All Kind of Polymer Waste Using Ferric Oxide because experimental main goal was all kind of polymer waste to crude oil production

Get Price

Delivery of the gasoline from the refinery to terminals and retail sites. World first. This project is claimed to be the first in which an ethanol production plant is being built and integrated at an existing oil refinery to produce waste and residue based ethanol on a sustainable basis.

Get Price

Palm oil mill effluent, or POME, is the effluent generated from the final stages of palm oil production in the mill. For every tonne of crude palm oil extracted from milling, about 2.5 tonnes of POME is generated ( Sulaiman et al., 2009 ), and in 2005, about 66.8 million tonnes of

Get Price