Oil: crude and petroleum products explained Refining crude oil. Basics; The refining process; Inputs & outputs; Refinery rankings +Menu Top 10 U.S. refineries operable capacity* As of January 1, 2025 ... Refinery yield; Oil refining and processing data; Articles on refining; Also on Energy Explained; Oil: crude and petroleum products; Oil ...

An overview of and data on inputs of crude oil and other liquids in oil refineries and resulting products of oil refining. U.S. Energy Information Administration - EIA - Independent Statistics and Analysis ... (called lease condensates); natural gas plant liquids ... U.S. refineries produced an average of about 44.7 gallons of refined products ...

Get Price

The oil refining process is the central activity of downstream oil and gas companies. In the refining process, crude oil is refined to produce different petroleum products like gasoline, diesel ...

Get Price

The rise of makeshift refining, as crude oil could still be pumped up and exported, soon became a viable source of income for local civilians, as these unsustainable coping strategies were needed to compensate for unemployment.

Get Price

At several stages in oil refining, filtration is required to be carried out. Oil Filter Press or PLF will remove the solid impurities and sediment particles from the oil making the final refined oil as clean and clear. Filtration is usually done 2 or 3 or even 4 times sometimes.

Get Price

argentina processing crude cooking oil refinery plant in vietnam. Processing & refining - Glencore. In these facilities we produce crude oil, refined oil, biodiesel, glycerine, refined sugar and feed meals.

Get Price

Oil refiners worldwide are reducing output or considering production cuts as the coronavirus outbreak keeps people at home and paralyses air travel, causing an unprecedented drop in fuel demand.

Get Price

Most refineries focus on producing transportation fuels. On average, U.S. refineries produce, from a 42-gallon barrel of crude oil, about 19 to 20 gallons of motor gasoline, 11 to 12 gallons of distillate fuel, most of which is sold as diesel fuel, and 4 gallons of jet fuel. More than a dozen other petroleum products are also produced in ...

Get Price

The Refining and Marketing segment refines crude oil and other feedstocks at its refineries in the Gulf Coast and Midwest regions of the United States; purchases ethanol and refined products for ...

Get Price

How crude oil is refined into petroleum products. Petroleum refineries change crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocks for making chemicals.. Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products.

Get Price

Oil refiners worldwide are reducing output or considering production cuts as the coronavirus outbreak keeps people at home and paralyses air travel, causing an unprecedented drop in fuel demand.

Get Price

12 琛?#0183; Energy Information Administration EIA Official Energy Statistics from the U.S. Government

Get Price

Oil refiners worldwide are reducing output or considering production cuts as the coronavirus outbreak keeps people at home and paralyses air travel, causing an unprecedented drop in fuel demand.

Get Price

2-10t/d Oil Refining Crude Oil Refinery Plant For Pure Refined Oil,Oil Refinery Plant For Product Oil,Flaxseed Oil Refining,Find Complete Details about 2-10t/d Oil

Get Price

As we know that crude vegetable oil needs complete processing to make it edible and pure. Hence we put through series of oil refining techniques which including degumming, neutralization, bleaching and

Get Price

04.06.2025· How to use oil refining machine? mini capacity cooking oil refinery machine mainly applied some small oil workshops or . https://goo.gl/RfJQzQ.

Get Price

Referring to oil refining, the character of impurities contained in crude oil, and the purpose of refined oil must be concerned. Machinery will customize the oil refinery process and solution for each of customer depending on their specific situation and needs. So called efinery generally refers to deacidificationprocess. But in the

Get Price

The oil refining/marketing sector includes companies that refine and sell crude oil. Companies that refine oil manufacture it into a number of petroleum products, including gasoline, jet fuel and

Get Price

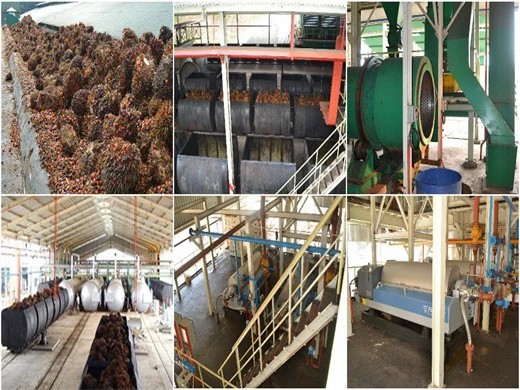

The palm oil refining process is quite identical. There are two routes are taken to process crude oil into refined oil; which are chemical (basic) refining and physical refining. The methods differ basically in the way the fatty acids are removed from the oil. Physical refining, which eliminates the need for an effluent plant for the soap stock

Get Price

Manufacturing Batch type palm kernel oil refinery plant,A batch type palm kernel oil refinery plant is the most widely used system to refine different oils. This batch type palm kernel oil refinery plant is generally used for smaller capacity plants ranging from 1 Tons per Day to 30 Tons per Day.

Get Price

refining process. For example, you wouldn put crude oil in the gas tank of your car! It has to be refined into gasoline first! Today, crude oil is refined all over the world. The largest oil refinery is the Paraguana Refining Complex in Venezuela, which can process 940,000 barrels of oil each day. In

Get Price

Crude oil is oil as it comes out of the ground. It contains a mix of many different petrochemicals and also impurities. Refining is the process of removing the impurities and also fractionating the oil into it's different chemicals. The chemicals

Get Price

However, base oils and lubricants remain a small part of the total refining picture and base oil prices and economics are still inextricably tied to crude oil and refined products. With a few notable exceptions, base oils are produced in facilities that are integrated with refineries producing fuels and other refined

Get Price

On the other hand, selling it means you expect the crack spread to weaken, or you think refining margins are deteriorating either due to crude oil prices climbing and/or demand for the refined

Get Price

Close-up. The Three Stages of Refining. Crude oil needs to be processed before it can be used (See Close-Up: "Why Crude Oil Needs to be Refined").Three major types of operation are performed to refine the oil into finished products: separation, conversion and treating.

Get Price

The oil refining fitness check evaluated how the EU petroleum refining sector is affected by ten of the most relevant pieces of EU legislation in the fields of environment, climate action, taxation and energy. The analysis covered a wide range of important aspects including five key evaluation criteria (effectiveness, efficiency, coherence

Get Price

Coconut Oil Refining Process The refined organic coconut oil is processed using the organically approved methods of physical extraction and refining. For the extraction step, the coconuts are broken into pieces and the coconut meat is allowed to dry, and once it is dried, the meat or flesh of the Coconut is hydraulically pressed at 100 130 degrees to extract the oil.

Get Price

The crude oil has been partially refined at the production platform where most of the water, grit, gas and sand will have been removed before the oil is sent ashore via the subsea pipelines by the oil export pumps. Once received at the oil refinery the oil is desalted and heated, most of it vaporising as it is pumped into the atmospheric distillation unit for separating mixtures when refining

Get Price

The bestis always cold pressed oils as it is pure and natural. Cold pressed cooking oils are made at low temperature, below 40 degree celsius. This retains all the nutrients in oilseeds. Refined (heat-pressed) oils on the other hand, heats the oil...

Get Price

Oil prices have plunged to one-year lows, but refiners in certain parts of the U.S. are not benefitting from cheaper crude. According to new data from the EIA, refining margins for motor gasoline

Get Price

Referring to oil refining, the character of impurities contained in crude oil, and the purpose of refined oil must be concerned. Machinery will customize the oil refinery process and solution for each of customer depending on their specific situation and needs. So called efinery generally refers to deacidificationprocess. But in the

Get Price

Edible oil refinery plant manufacturer supplies high quality edible oil refining, dewaxing and factionation machine with factory price and mature oil refining process technology and provide turn-key projects of edible oil refinery plant for you.

Get Price

The Company also owns a 49% stake in one of India's largest high-tech refineries, Vadinar, which has a capacity of 20 million tons of crude oil per year. Refining volumes at German refineries in 2025 amounted to 11.5 million tons. Refining of Mozyr Oil Refinery's crude oil

Get Price

Ever wondered how an oil refinery works? Now you can learn more about the technology involved in refining crude oil into the thousands of petroleum-based products you use everyday. Refinery Processes. Crude oil refineries employ some of the United Statestop scientists, engineers, and safety professionals to ensure that products are produced

Get Price

The crude oil has been partially refined at the production platform where most of the water, grit, gas and sand will have been removed before the oil is sent ashore via the subsea pipelines by the oil export pumps. Once received at the oil refinery the oil is desalted and heated, most of it vaporising as it is pumped into the atmospheric distillation unit for separating mixtures when refining

Get Price

Petroleum refining in the United States in 2013 produced 18.9 million barrels per day of refined petroleum products, more than any other country. Although the US was the world's largest net importer of refined petroleum products as recently as 2008, the US became a net exporter in 2010, and in 2014 was the largest exporter and the largest net exporter of refined petroleum.

Get Price

The products are stored on-site until they can be delivered to various markets such as gas stations, airports and chemical plants. In addition to making the oil-based products, refineries must also treat the wastes involved in the processes to minimize air and water pollution.

Get Price

Oil refiners worldwide are reducing output or considering production cuts as the coronavirus outbreak keeps people at home and paralyses air travel, causing an unprecedented drop in fuel demand.

Get Price