Pretreatment is necessary for efficient oil extraction from raw palm kernel. In palm kernel oil industrial production, oil raw materials are usually palm kernel or pressed cake. If the material is palm kernel, the main pretreating steps are palm nut cleaning, shelling and separation, crushing, flaking and steamed frying.

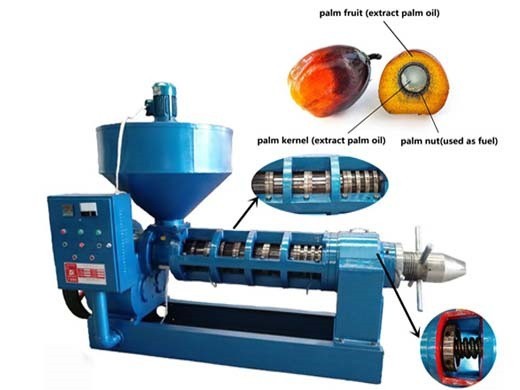

The pretreated palm kernel material is then transferred to the screw oil press for extraction. Equipped with the automatic temperature-controlling device and crude oil filter tank, Our integrated screw oil press operates easily and has high oil output.

Get Price

Palm kernel oil pressing. Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing.

Get Price

Palm oil is one type popular fry oil. China is one of biggest import palm oil countries all over the world. Our company is professional in manufacturing palm oil extraction press machine, palm kernel oil extraction press machine, both single machine and complete line.

Get Price

The process of palm kernel oil production involves a series of professional palm kernel oil extraction machine for cleaning, screw pressing, breaking, filtering and storage. Acquiring efficient and high-quality palm kernel oil extraction machine will save costs on the maintenance and repairs of these processing machines.

Get Price

A detailed palm kernel oil production business plan is important for someone who want to built a palm kernel oil mill plant.A thoughtful palm kernel oil production business plan will be essential for the long-term palm kernel oil production.This artical will give you a general introduction.Hope help u.

Get Price

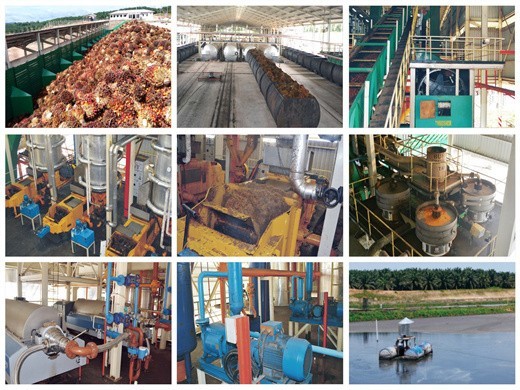

Palm oil production line includes three sections, palm oil pressing plant, palm oil refinery plant and palm oil fractionation plant. As the manufacturer of the palm oil production line, we can offer the whole line or part of the palm oil production line for different capacities with turnkey services.

Get Price

Pretreatment is necessary for efficient oil extraction from raw palm kernel. In palm kernel oil industrial production, oil raw materials are usually palm kernel or pressed cake. If the material is palm kernel, the main pretreating steps are palm nut cleaning, shelling and separation, crushing, flaking and steamed frying.

Get Price

Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing. Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil

Get Price

Palm oil processing line is an important production line of extracting palm oil,the palm oil processing line mainly includes: palm oil press production line and palm oil refinery line.The palm oil processing line can help you get standard edible oil or provide qualified material for deep processing products.The production capacity of the palm oil processing line can be adjusted according to

Get Price

Palm oil is one type popular fry oil. China is one of biggest import palm oil countries all over the world. Our company is professional in manufacturing palm oil extraction press machine, palm kernel oil extraction press machine, both single machine and complete line.

Get Price

Complete palm kernel oil extraction plant is capital oriented business, so both the design of palm kernel oil plant and the extraction machine of palm oil will take up a large part of the business investment. Full scale palm kernel oil extraction factory requires various professional forces for different processing or production stages.

Get Price

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

Get Price

A detailed palm kernel oil production business plan is important for someone who want to built a palm kernel oil mill plant.A thoughtful palm kernel oil production business plan will be essential for the long-term palm kernel oil production.This artical will give you a general introduction.Hope help u.

Get Price

Explaining the process of producing palm kernel oil in Akwa Ibom state Palm oil milling plant / Palm fruit oil palm kernel oil production line 60tpd palm kernel oil extraction machine

Get Price

Pretreatment is necessary for efficient oil extraction from raw palm kernel. In palm kernel oil industrial production, oil raw materials are usually palm kernel or pressed cake. If the material is palm kernel, the main pretreating steps are palm nut cleaning, shelling and separation, crushing, flaking and steamed frying.

Get Price

Palm Kernel Oil Extraction. Generally, palm kernel extraction is separated from palm oil extraction. Most small and medium palm oil mills are not designed with palm kernel processing unit, but selling the kernel to other oilseeds extraction plant (such as copra, shea nuts, cottonseeds, coconut seeds, rapeseed, groundnuts and so on).

Get Price

Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing. Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil

Get Price

Palm oil is one type popular fry oil. China is one of biggest import palm oil countries all over the world. Our company is professional in manufacturing palm oil extraction press machine, palm kernel oil extraction press machine, both single machine and complete line.

Get Price

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

Get Price

The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved o chemical production

Get Price

A detailed palm kernel oil production business plan is important for someone who want to built a palm kernel oil mill plant.A thoughtful palm kernel oil production business plan will be essential for the long-term palm kernel oil production.This artical will give you a general introduction.Hope help u.

Get Price

Threshing section of palm oil production: The purpose of threshing is to separate oil palm fruit from the fruit bunch through strong vibration. 4. Palm oil pressing section of palm oil production: Before pressed, oil palm fruit first be carried out cooking, sterilized fruit must be re-heated to make the pulp soft and damage pulp cell structure.

Get Price

Receiving section of raw material Palm oil press mill plant mainly make crude palm oil (CPO) by processes the extraction of fresh fruit bunches (FFB) collected by pressing and separate . 1.The main processes are: fresh fruit bunch receivi

Get Price

Oil Press Machine, Oil Expeller, Oil Press manufacturer / supplier in China, offering Corn Germ Soybean Sunflower Walnut Almond Hemp Groundnut Palm Kernel Coconut Oil Mill Making Extraction Press Machine, Small Manual Auto Clay Brick Machine, Clay Brick Block Making Machine, 1-5t/H Small Scale Africa Palm Oil Screw Press Making Extraction Production Processing Line Equipment Plant Machine and

Get Price

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

Get Price

1.The Palm fruit is conveyed to the mashing tank by screw conveyor 2.The mashing tank will break the fruit and heat it and discharge it to the press 3.The press squeezes the oil and the cake is used as a fuel for a steam boiler...

Get Price

Palm oil is one type popular fry oil. China is one of biggest import palm oil countries all over the world. Our company is professional in manufacturing palm oil extraction press machine, palm kernel oil extraction press machine, both single machine and complete line.

Get Price

A detailed palm kernel oil production business plan is important for someone who want to built a palm kernel oil mill plant.A thoughtful palm kernel oil production business plan will be essential for the long-term palm kernel oil production.This artical will give you a general introduction.Hope help u.

Get Price

Palm kernel oil is also able to be used for many other purposes, e.g. pomade (body cream), medicine, frying fish, making stew, making soap, etc. Difference between palm fruit oil and palm kernel oil. Palm kernel oil comes from the innermost kernel, or nut-like core of the plant, palm fruit oil, however, comes from the fleshy, orange part of the

Get Price

The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved o chemical production

Get Price

Walnut oil press equipment adopts twice pressing method to obtain walnut oil.The equipment mainly includes walnut hulling machine, walnut shelling machine, hydraulic oil press, screw oil press, walnut oil refining equipment, etc. Walnut processing equipment can retain the nutrition in the walnut kernel, has high oil yield and low residual oil rate in the cake.

Get Price

Palm Kernel Oil Processing Machine Palm Kernel Oil Production Line Palm Kernel Oil Extraction Machine , Find Complete Details about Palm Kernel Oil Processing Machine Palm Kernel Oil Production Line Palm Kernel Oil Extraction Machine,Palm Kernel Oil Processing Machine,Palm Kernel Oil Extraction Machine,Palm Kernel Oil Production Line from Oil Pressers Supplier or Manufacturer-Zhengzhou Shuliy

Get Price

1.The Palm fruit is conveyed to the mashing tank by screw conveyor 2.The mashing tank will break the fruit and heat it and discharge it to the press 3.The press squeezes the oil and the cake is used as a fuel for a steam boiler...

Get Price

Palm oil is one type popular fry oil. China is one of biggest import palm oil countries all over the world. Our company is professional in manufacturing palm oil extraction press machine, palm kernel oil extraction press machine, both single machine and complete line.

Get Price

Vegetable Oil Press, Palm Oil Mill Plant, Cooking Oil Refinery Plant manufacturer / supplier in China, offering Small Manual Auto Clay Brick Machine, Clay Brick Block Making Machine, Corn Germ Soybean Sunflower Walnut Almond Hemp Groundnut Palm Kernel Coconut Oil Mill Making Extraction Press Machine, 1-5t/H Small Scale Africa Palm Oil Screw Press Making Extraction Production Processing Line

Get Price

Biodiesel production line adopts high efficiency biodiesel technology at high temperature to obtain biological diesel oil as renewable source. This environmental protective and reproductive biodiesel is available under certain temperature, pressure, catalyst, and form fatty acid methyl ester, and through high vacuum distillation and

Get Price

A detailed palm kernel oil production business plan is important for someone who want to built a palm kernel oil mill plant.A thoughtful palm kernel oil production business plan will be essential for the long-term palm kernel oil production.This artical will give you a general introduction.Hope help u.

Get Price

04. Oil Extracion (Small Palm Oil Screw Press) Extraction of the oil is then done after digestion of the fruits. Extraction can be done using two methods that are the 'dry' method and 'wet' method. The dry method involves the use of mechanical presses while the wet method uses hot water, which leaches oil out.

Get Price