Large palm oil mill plant place the fruit in rotary drums to complete this process, while small palm oil production facilities perform threshing by hand. Palm fruuit threshing machine mainly used to separate palm fruit from palm fruit bunches. After threshing, the next step in palm oil production involves pressing the fruit to separate the oil ...

Palm oil mill effluent (POME) generated from palm oil milling processes to produce crude palm oil (CPO) is the most polluting agro-industrial effluent. It is estimated that 0.5.75 tonne of raw POME were produced for every tonne of fresh fruit bunches (FFB) processed (Yacob et al., 2006).

Get Price

Palm oil mill process of oil clarifying: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. Oil by centrifugal separation and through vacuum drying pumped into the ...

Get Price

Crude Oil Process with GEA topd 3-Phase Decanters The crude oil process with 3-phase decanters does not need vertical clarifiers and sludge tanks. The pressed and de-sanded palm oil in this process is sent directly to the topd 3-phase decanter. The main advantage is to be seen in a much shorter process time and lower oil losses.

Get Price

Crude Palm Oil Mill Process Introduction:. 1.Weighing.Palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.Loading ramp.FFB after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank.

Get Price

Who We Are Leading manufacturer of edible oil mechanical equipment. Factory with more than 30 years manufacturing experience. School-enterprise partner of Henan Technology University. What We Do 10-500T/H oil material first cleaning,drying and storage section turn-key project. 100-3000T/D oil pretreatment,shelling and pre-press workshop turnkey project (soybean hot peeling ...

Get Price

Our fractionation project adopts dy fractionation process. We have posted the advantages and disadvantages of 3 common fractionation process of palm oil production which showed why dry fractionation is the best choice. The typical fractionation process of palm oil mill is pre-heating, cooling, crystallization, and filtering.

Get Price

A palm oil mill produces crude palm oil and kernels, as primary products and biomass as secondary product. The capacity of mills varies between 60- 100 tons FSlideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

Get Price

Crude Oil Process with GEA topd 3-Phase Decanters The crude oil process with 3-phase decanters does not need vertical clarifiers and sludge tanks. The pressed and de-sanded palm oil in this process is sent directly to the topd 3-phase decanter. The main advantage is to be seen in a much shorter process time and lower oil losses.

Get Price

Crude Palm Oil Mill Process Introduction:. 1.Weighing.Palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.Loading ramp.FFB after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank.

Get Price

Palm oil is derived from the flesh of the fruit of the oil palm species E. Guineensis. In its virgin form, the oil is bright orange Read more. Palm Oil Plantation. The Oil Palm Tree. The Oil. Health & Nutrition. Palm Oil & The Environment. The Tree of Life. Palm Oil Industry. Palm Oil Industry. Industry Overview. Malaysian Palm Oil Industry. Processing Flow Chart. Market Statistic & Prices

Get Price

Palm oil mill effluent (POME) generated from palm oil milling processes to produce crude palm oil (CPO) is the most polluting agro-industrial effluent. It is estimated that 0.5.75 tonne of raw POME were produced for every tonne of fresh fruit bunches (FFB) processed (Yacob et al., 2006).

Get Price

2. Palm oil mill process of sterilizer: Fresh palm fruit bunch are airtight sterilized in sterilizer, injecting direct steam (the pressure is 300KPa) to heat 60mins. The purpose is to prevent enzymes broken down, avoiding FFA content in oil further increase.

Get Price

There, the remaining oil is recovered, while palm oil mill effluent (POME) and solid waste are separated. The latter can be used as organic fertilizer in the plantation. Palm Kernel Crushing Plant. After digestion of the palm fruit and extraction of the palm oil from the mash, the nuts and fibers are recovered. First they are dried and

Get Price

Palm kernel oil expeller machinery. Palm oil mill process. Palm oil processing line. Small scale palm oil refining plant. Palm kernel cracking and separating machine in Nigeria. 2tpd palm kernel oil refining machine. PKO processing machine. 30-500tpd palm oil refining machine. Crude palm oil refining process

Get Price

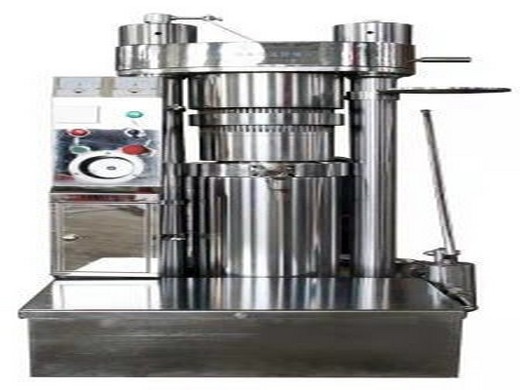

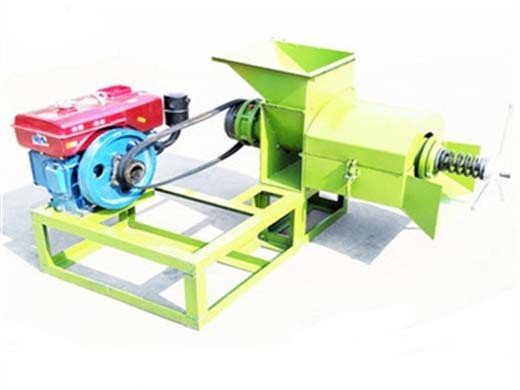

An oil mill is a grinding mill designed to crush or bruise oil-bearing seeds, such as linseed or peanuts, or other oil-rich vegetable material, such as olives or the fruit of the oil palm, which can then be pressed to extract vegetable oils, which may used as foods or for cooking, as

Get Price

Flow chart of the production chain of palm oil and palm kernel oil products for food application in the EU (1) Cultivation of palm fruits Transport to the oil mill Palm fruits (2) Production of crude oil Processing of fruit bunches Drying and processing of palm kernels Palm kernels Storage and transport Crude oil (A) Transport Storage

Get Price

Our fractionation project adopts dy fractionation process. We have posted the advantages and disadvantages of 3 common fractionation process of palm oil production which showed why dry fractionation is the best choice. The typical fractionation process of palm oil mill is pre-heating, cooling, crystallization, and filtering.

Get Price

Palm oil mill/palm oil extraction machine runing video.palm oil mill process palm &Palm fruit to cooking oil video.palm oil mill machinery production video.

Get Price

Contact us about palm oil mill,palm oil mill machinery,palm oil mill project,palm oil productions, palm oil extraction machine and palm oil refinery machin

Get Price

he app retrieves the product barcode and determines if the product contains palm oil. If so, you can see alternatives to palm oil-free products. The application will not only make it easier for you to choose an environmentally friendly and healthier product, but will also give the manufacturer anot

Get Price

Palm Oil processing gives rise to highly polluting waste-water, known as Palm Oil Mill Effluent (POME), which is often discarded in disposal ponds, resulting in the leaching of contaminants that pollute the groundwater and soil, and in the release of methane gas into the atmosphere.

Get Price

dewatering, the palm oil mill operator is looking for low energy consumption and low maintenance. The TurboJet system allows a 15 to 20% reduction in power consumption, and the ANDRITZ decanter centrifuge is maintenance-friendly as well, with very competitive Advantages in various stages of the palm oil process with ANDRITZ decanter centrifuges

Get Price

POME (Palm Oil Mill Effluent) TREATMENT PLANTS. We are the first to develop Innovative, Proven & State of Art Technology PHB鈩⑩€?(Zero Pond鈩? Zero Pollution鈩?& Higher Biogas鈩?. This system is widely used for POME against the conventional systems. The conventional system consists of series of ponds which are uncovered open ponds

Get Price

Written by Mark Barthel, Steve Jennings, Will Schreiber, Richard Sheane and Sam Royston (3Keel LLP) and James Fry, Yu Leng Khor, Julian McGill (LMC International Ltd. (February 2025) Study on the environmental impact

Get Price

Process of Small Palm Oil Mill Plant. There is a wide range of techniques used for processing palm oil fruits into edible oil, cooking oil or bio-diesel oil. These techniques are categorized according to the complexity degree of the machinery being used in the operational unit. This categories include use of traditional methods with more manual involvement and automatic industrial mills in

Get Price

Process of Small Palm Oil Mill Plant. There is a wide range of techniques used for processing palm oil fruits into edible oil, cooking oil or bio-diesel oil. These techniques are categorized according to the complexity degree of the machinery being used in the operational unit. This categories include use of traditional methods with more manual involvement and automatic industrial mills in

Get Price

New palm oil mill processes are characterized by advanced oil separation technologies with zero dilution water (CO-Dfor example as a new system for oil recovery without dilution water) and continuous sterilization of the fresh fruit bunch (FFB).

Get Price

ADM is working to reduce and mitigate palm supply chain risks through transparency & traceability, supplier engagement & risk identification, transformation, and monitoring & verification. Action Plan 2025-2025 Palm Oil Action Plan. Traceability Scores. Progress Reports H2 2025 Progress Report H1 2025 Progress Report H2 2025 Progress Report

Get Price

As a result, palm oil wastewater treatment also receives much attention. Palm oil mill effluent (POME)is a yellow liquid with a unique unpleasant smell and comes from oil extraction, cleaning and washing process in the POME factory, which is featured with very high COD and BOD.

Get Price

In recent decades, Malaysia has been known as one of the world leading producers and exporters of palm oil products. Every year, the number of palm oil mills increases rapidly, thus increasing the capacity of fresh fruit bunch waste or effluent discharge. Based on the data from the Malaysian Palm Oil Board in 2012, Malaysia produced 99.85 million tons of fresh fruit bunch (FFB) per year

Get Price

Indonesia, Malaysia, Thailand and Colombia are the 4 largest producer and exporter of palm oil production. With the boom of oil palm industry, there are large quantities of biomass waste generating from palm oil mills. These main wastes are empty

Get Price

Type: Process Pump Materials: Cast iron, ductile iron, bronze, cast steel, stainless steel DN (mm): D: up to 400 m 3 /h H: up to 100 m Ns: up to 3600rpm. Applications: Wastewater treatment, Crude palm oil processing, Petrochemical, Chemical.

Get Price

From the mill processing of oil palm will be got CPO and PK, while their cost combined in one total cost of production, and how it can be compute seperately. One of the two product is CPO as the main product, and another is PK as by-product. There are four methods of computation in cost of production for the two products. But the first two methods and the third are not suitable to be used as

Get Price

The feasibility of using these oil palm biomass and Palm Oil Mill Effluent (POME) as a feedstock for bioenergy production has received overwhelming interests worldwide in the effort to confront the energy crisis. This chapter discusses the availability, demand, and potential and future direction of oil palm resources from oil to biomass waste

Get Price

Palm oil is obtained by different traditional and mechanized methods ranging from processing uncooked or cooked fruits to centrifugation of mashed boiled or de-pericarped palm fruits. Palm oil and palm kernel oil can be extracted form oil palm fruits mesocarp and palm kernel respectively, using very simple equipments and techniques. However

Get Price