It is unnecessary to build up your palm oil milling plant around the market since you don’t sell produced palm oil to the customer directly. The good location for setting up palm oil plant factory is nearby oil palm plantation farm or at least close to place of rich oil palm supply. In addition, it should have good transportation system.

Therefore, the exact cost of setting a palm oil processing mill plant in Nigeria would vary from the different requirements and specific situations. The following data is just for reference: A complete palm oil processing mill plant with a capacity of 50 ton/day is about $ 60,0000, while a full complete palm kernel oil production line with capacity of 10 ton/day is $ 60,000 around. ...

Get Price

New type palm oil processing plant gradually introduced to Ghana. With the development of the world economy, more and more investors have paid attention to the palm oil industry, they began to invest in the palm oil industry, began to set up palm oil mill plant to produce palm oil and make money.

Get Price

Since the mid-1990s, red palm oil has been cold-pressed from the fruit of the oil palm and bottled for use as a cooking oil, in addition to other uses such as being blended into mayonnaise and vegetable oil. Oil produced from palm fruit is called red palm oil or just palm oil.

Get Price

Palm oil processing machine is used to extract crude palm oil from palm fruit and get high oil yield palm oil. Palm oil processing machine, also called as palm oil extraction machine, are utilized in palm oil mill or palm oil pressing plant for effective palm oi production.

Get Price

Rather than “palm oil”, it should really be called “palm fruit oil.” Because the oil is obtained through pressing the pulp of this fruit, which has a 50% fat content. This extraction is done through simple hot-pressing, without solvents or chemical additives. A very high-yield plant

Get Price

The Forum for Sustainable Palm Oil currently has 49 members, including companies, non-governmental organisations, associations and the German Federal Ministry of Food and Agriculture (BMEL). The aim of FONAP is to boost significantly the proportion of sustainably produced palm oil on the German, Austrian and Swiss markets and to improve ...

Get Price

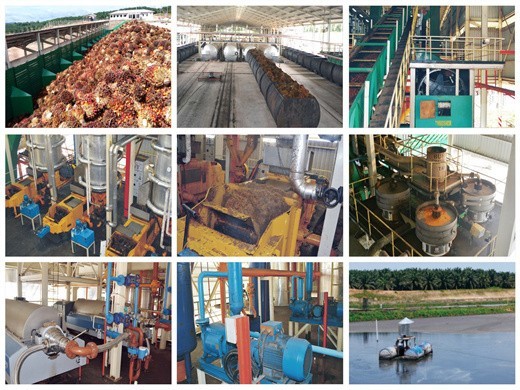

The oil winning process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export.

Get Price

This palm oil mill plant was produced by Henan Doing Company.This palm oil mill plant can process palm fruit 80-100tph.The complete set of palm oil mill plant is a complex process which include ...

Get Price

We offer 198 produced palm oil pressing plant products. About 100% of these are oil pressers. A wide variety of produced palm oil pressing plant options are available to you, such as automatic, semi-automatic.

Get Price

Peanut Oil Pressing Methods. Generally, the husk content of peanut is 30-35%, and the oil content in peanut kernel is 40-50%. Therefore, the peanut pretreatment processes include cleaning, dehusking and separating of hull & kernels. According to pressing temperature, there are two peanut oil pressing technologies: hot pressing and cold pressing.

Get Price

Supply turnkey palm oil pressing plant and all kinds of quality palm oil machines including palm oil press, palm oil expeller and filter with competitive price. Send an inquiry now and tell us your budget, situation and other requirements. Then we can guide you starting palm oil pressing and refinery business step by step.

Get Price

Palm kernel oil is usually obtained from pressing and extracting the oil from the palm kernel nuts through a press machine. After pressing, the palm kernel oil in its crude state becomes solid with a taste and smell. This is followed by a refinery process to turn the oil into a

Get Price

Palm oil is derived from the fruit of the oil palm tree, which is grown in tropical regions of Asia and Africa. While palm oil producers rely on different techniques to extract this oil, the basic steps involved in palm oil production remain the same. Manufacturers must plant a supply of oil

Get Price

Small to Medium Sized Palm Oil Mill Plant Flow Chart. The typical processes to produce palm oil include palm bunches reception, palm bunches sterilization, palm threshing, palm fruit digestion, palm pulp pressing, palm oil clarification, palm oil drying and palm oil storage and packing. Palm

Get Price

Small Oil Pressing Lines Setup Advantages. Oil pressing and production can be done in oil mill plant. Usually there are three types of oil mill, small scale, medium scale and large scale. The conditions of starting a small scale oil pressing line is relatively simple and easy, especially for novice in oil processing industry.

Get Price

5~10TPD Small Scale Oil Refinery Plant for Palm Kernel Oil. Machinery is professional oil refinery machinery supplier in China, the small scale oil refinery plant, with capacity of 5 ~10 tons per day, has been the area of excellence of our company.It is available for palm kernel oil, corn germ oil, peanut oil, soybean oil, sunflower seed oil, rape seed oil, rice bran oil, coconut oils and

Get Price

Peanut Oil Pressing Methods. Generally, the husk content of peanut is 30-35%, and the oil content in peanut kernel is 40-50%. Therefore, the peanut pretreatment processes include cleaning, dehusking and separating of hull & kernels. According to pressing temperature, there are two peanut oil pressing technologies: hot pressing and cold pressing.

Get Price

Cooking oil manufacture involves cleaning the seeds, grinding them, pressing, and extrading the oil from them. In extracting, a volatile hydrocarbon such as hexane is used as a solvent. After extracting, the oil is refined, mixed with an alkaline substance, and washed in a centrifuge.

Get Price

Qie GROUP is a leader manufacturer of palm oil machine, here you can see palm oil refinery machine detials, palm oil extraction machine installation information,palm kernel oil refinery line, and project reports of crude palm oil refinery machine,palm oil mill plant etc.

Get Price

There are many factors that affect the efficiency of oil extraction, such as vegetable seed types, temperature, press configuration, etc. Usually, the physical pressing method has an oil output of 65-70%, which is suitable for commercial processors to build small and medium screw pressing oil plant.

Get Price

Proposed plan for operation of a Palm Oil Mill (adapted from [28]) Palm oil mills in Malaysia typically meet most of their electricity and process steam requirements by burning some of the wastes, with energy for start-up generally being provided by back-up diesel [13,28,30]. Not all of the wastes are burnt.

Get Price

Palm Fruit Oil Pressing Machine,Palm Oil Processing Machine For Palm Oil Mill,The Fresh Fruit Bunches(FFB) is available after 3 yeas plantation. Palm fruits are sent into crude palm oil processing plant with following production process: 3.Every set of euipment produced

Get Price

Palm oil mill plant adopts the most scientific palm oil processing equipment configuration, using mechanical oil pressing technology, make successfully extraction of palm oil from palm fruit. Palm oil milling process plant covers three major plants of crude palm oil pressing plant, water treatment plant and power supply plant.

Get Price

Soybean oil production plant for sale, supplied by BEST Machinery famous oil mill machinery manufacturer in Asia. We can offer both soybean oil pressing plant and solvent extraction machinery. Feel free to contact us for detailed information! Turnkey Projects of Soybean Oil Production Oil Pressing Section

Get Price

MBL is a major palm kernel oil expellers manufacturer in Malaysia. We design and manufacture palm kernel oil seed expellers primarily for extraction of palm kernel oil. The palm kernel oil seed expellers comprise primarily the pressing stations, coupling, gearbox, pulley and belt, and motor.

Get Price