In particular, POME is a basic expression referring to the effluent from the last phases of palm oil manufacture in the mill. It incorporates different fluids, dirt, leftover oil and suspended solids. POME in its untreated shape is a high quality waste, relying upon the operation of the procedure.

Biodiesel Production from Palm Oil, Its By-Products, and Mill Ef铿倁ent: A Review Khairul Azly Zahan 1,2 ID and Manabu Kano 1,* ID

Get Price

The sustainability of petroleum-based fuel supply has gained broad attention from the global community due to the increase of usage in various sectors, depletion of petroleum resources, and uncertain around crude oil market prices. Additionally,

Get Price

Anaerobic digestion is widely used as a primary treatment for palm oil mill effluent. Biogas is produced in the process in the amount of 20 m 3 per ton FFB. This effluent could be used for biogas production through anaerobic digestion. At many Palm-oil mills this process is already in place to meet water quality standards for industrial effluent.

Get Price

Palm oil mill effluent is a fresh product available in the vicinity of oil palm mills. Environmental impact Palm oil mill effluent is a highly polluting material, due to its high biological oxygen demand (BOD), low pH and colloidal nature.

Get Price

The generation of palm oil mill effluent (POME) alongside with the production of crude palm oil has created environmental issue for the palm oil mill industry in Malaysia due to its polluting characteristics. POME with its high organic content is a source with great potential for biogas production.

Get Price

Considering the importance of this topic, this paper focuses on the use of palm oil, its by-products, and mill effluent for biodiesel production. Palm oil is known as an excellent raw material

Get Price

The sustainability of petroleum-based fuel supply has gained broad attention from the global community due to the increase of usage in various sectors, depletion of petroleum resources, and uncertain around crude oil market prices. Additionally,

Get Price

Palm oil mill effluent (POME) has been classified as highly pollutant-containing wastewater with thick brownish viscous liquid waste and has an unpleasant odour.

Get Price

Palm Oil processing also gives rise to highly polluting waste-water, known as Palm Oil Mill Effluent, which is often discarded in disposal ponds, resulting in the leaching of contaminants that pollute the groundwater and soil, and in the release of methane gas into the atmosphere. POME could be used for biogas production through anaerobic

Get Price

Palm oil mill effluent (POME) is generated from the sterilization, condensation and hydrocycloning of palm oil in mills. If the effluent is discharged into the aquatic and terrestrial ecosystem without treatment, it could lead to high biological oxygen demand (BOD), chemical oxygen demand (COD) and acidic pH of the receiving waters.

Get Price

Removal of Solids from Palm Oil Mill Effluent and Paint Wastewater Using Electrocoagulation Technique. Link/Page Citation 1. As such, several raw material, intermediate products, and wastes are brought into water during industrial processes [4]. In other words, wastewater is a major pollutant source into the environment.

Get Price

Some 400 mills each produce huge amounts of waste, including kernels and husks from pressed fruits, discarded branches and waste water known as Palm Oil Mill Effluent (POME). All of which is

Get Price

Water Treatment for Palm Oil Mill Effluents (POME) Creating sustainable solutions for the Palm Oil Mills through effective effluents treatment and resource recovery. Palm oil has become a major, global agricultural commodity, used for food and non-food applications and most recently touted as a promising feedstock for biofuel production.

Get Price

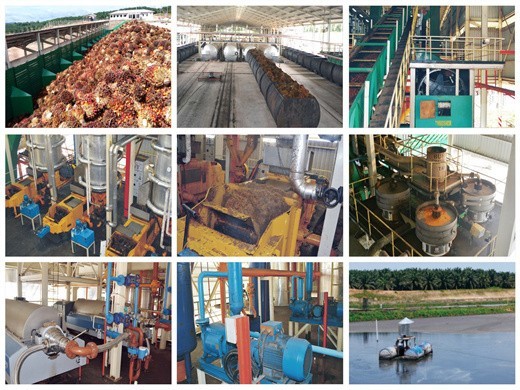

produced two major by-products, i.e. oil palm trunks (OPT) and oil palm fronds (OPT) whereas the latter produced empty fruit bunches (EFB), palm kernel cake (PKC), palm oil mill effluent (POME), palm press fiber (PPF) and shell. The availability of various types of residues in the oil palm environment has been reviewed (Zin 2000).

Get Price

In line with the crude palm oil production, the oil palm industry also produces by-products from two sources, namely from oil palm mills and oil palm plantation. The by-products from oil palm mills consist of shell, empty fruit bunch (EFB), pressed fruit fibers, palm oil mill, and effluent (POME), while the by-products from plantation comprises

Get Price

Along with the setting up of the palm oil production factory , the palm oil mill effluent is more and more serious. How to deal with the palm oil mill effluent will be an important problem for the investor.

Get Price

Engineers at the University of Nottingham Malaysia have developed new technology to help the global palm oil processing industry reduce CO2 emissions and create renewable energy from its waste.

Get Price

Palm Tree Introduction: Palm trees are grown in tropical regions perennial oil crops,has the advantages of big yields low cost.Palm oil is already one of the world largest edibel oil production,is widely used in large food processing,cooking and eating areas of bio-diesel production.Oil palm tree main producing area distributes tropic area between the south latitude 5锝?0掳and the north

Get Price

8 - Palm and Palm Kernel Oil Production and Processing in Malaysia and Indonesia. There is also an increasing trend in the utilization of by-products such as palm oil mill effluent (POME), EFB, palm fiber, and shell for the production of compost biofertilizer and fiber materials for various applications, as well as activated carbon.

Get Price

It has been reported that in 2005 there was a total of 423 palm oil mills having production capacity of approximately 89 million tonnes of fresh fruit bunch (FFB) per year. Waste from the oil palm mill process include palm oil mill effluent (POME), generated mainly from oil extraction, washing and cleaning up processes.

Get Price

South East Asia dominates the production of palm oil worldwide. During the traditional wet processing, palm oil mill effluent (POME) wastewater is generated which poses serious environmental problems. Wastewater treatment using microalgae was initiated recently because of the advantages to lower nutrient content efficiently while the biomass can be utilized as bulk biomass or value added

Get Price

Compared to conventional palm oil mills the total amount of palm oil mill effluent (POME) can be reduced from 0.65 m 3 t-1 FFB to 0.45 m 3 t-1 (conventional sterilization and zero dilution water) and 0.25 m 3 t-1 (continuous sterilization and zero dilution water). These changes influence the treatment processes and its cost significantly.

Get Price

Palm Oil processing gives rise to highly polluting wastewater, known as Palm Oil Mill Effluent (POME), which is often discarded in disposal ponds, resulting in the leaching of contaminants that pollute the groundwater and soil, and in the release of methane gas into the atmosphere.. Properties of POME. POME is an oily wastewater generated by palm oil processing mills and consists of various

Get Price

Palm oil production begins with palm oil seeds. As oil palms have a productive life of 25-30 years, the choice of seeds will impact production for decades to come. Asian Agri has developed its own Topaz seeds, which produce higher yields and are more resistant to pests than regular oil palms, increasing productivity of oil palm plantations.

Get Price

Palm oil mill effluent (POME) is a wastewater generated from palm oil milling activities which requires effective treatment before discharge into watercourses due to its highly polluting properties. The characterization of wastewater is the essential step in the design of any wastewater treatment plant (WWTP) in the industry as conducting pilot-scale tests to obtain design and operating

Get Price

Palm oil mill effluent treatment and utilization to ensure the sustainability of palm oil industries. The POME is the only byproduct that did not have a viable application until now. Palm oil mill effluent (POME) is acquired from local palm oil industry, Malpom Industries Sdn.

Get Price

The effect of oil and its derivative (long-chain fatty acids (LCFAs), and glycerol) in palm oil mill effluent (POME) on methane production and the microbial community were investigated. POME with oil concentration >1.6 g鈰匧鈦宦?could cause the imbalance of the anaerobic digestion (AD) process by decreasing methane yield, accumulation of

Get Price

A Review of Palm Oil Mill Effluent (Pome) Water Treatment. Specifically palm oil mill effluent (POME) is a to assess a more economical method of running a palm general phrase referring to the effluent from the final oil clarification plant [2] and utilizing the effluent water stages of palm oil production in the mill It includes or converting it

Get Price

454 palm oil mills. Malaysia covers about 30% of the world palm oil production and 34% of palm oil exports (Kushairi et al., 2025). The high production of FFB yields 19.92 million tonnes of crude palm oil (CPO), and huge quantity of by-product, i.e. palm oil mill effluent (POME). POME is rich in organic matter but could be contaminated due

Get Price

Environmental Management Guideline for the Palm Oil Industry 5.2 Utilisation of palm oil mill by-products 33 5.2.1 Utilisation of solid residues Thailand (1996). This is due to the specific conditions of the Palm Oil Mill effluent. These conditions and the reasons for the required standards are prescribed in the

Get Price

Specifically, palm oil mill effluent (POME), is a to assess a more economical method of running a palm general phrase referring to the effluent from the final oil clarification plant [2] and utilizing the effluent water stages of palm oil production in the mill. It includes or converting it to other useful products [19,20] and

Get Price

A single palm oil mill there are hundreds in Malaysia alone can buy fruit from a multitude of suppliers, and with all its formulations and derivatives, palm oil has one of the most

Get Price

The quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the FFBs and the process adopted. A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 2.5 - 150 MT FFB/hr.

Get Price

b> Releasing palm oil mill effluent in river is the cheapest way to discharge it. But environment problems come along, water depletion and aquatic pollution. c> Physical treatment of palm oil mill effluent includes stages such as screening, sedimentation and oil removal prior to the secondary treatment in biological treatment system.

Get Price

Palm oil mill effluent (POME) waste treatment plants cater all raw effluent produced. Approximately 0.65 tonnes of raw POME is produced for every ton of fresh fruit bunches (FFB) processed. In 2003, a total of 2,106,956 tonnes of FFB were processed, resulting in 1,369,521 tonnes of POME being produced. Enter MBL's EFB composting system.

Get Price

Palm oil processing operation is invariably accompanied by palm oil mill effluent (POME) considered to be an environmental pollutant. While anaerobic digestion and the present tertiary treatment technologies of POME are able to meet the current regulatory effluent discharge requirement of biological oxygen demand (BOD) 100 mg litre-1 the current limit set by the Department of Environment

Get Price

Chlorella sorokiniana CY-1 was cultivated using palm oil mill effluent (POME) in a novel-designed photobioreactor (NPBR) and glass-made vessel photobioreactor (PBR). The comparison was made on biomass and lipid productions, as well as its pollutants removal efficiencies. NPBR is transparent and is

Get Price

The waste water has high organic matter content, biochemical oxygen demand BOD is about 25000ppm, required by qualified deal before emissions. Pool sewage treatment system is the most used and effective treatment. This palm oil mill effluent treatment system is cost-effective, only needs adequate space, less investment costs.

Get Price