THE FIRST NAME IN HIGH SHEAR MIXERS CHEMICALS Refining of Vegetable Oils for Biofuels. There is considerable growth in the use of vegetable oils such as palm, rape seed, soybean, sunflower, etc. as an alternative to petroleum based diesels. Currently there are two options

Refining of Vegetable Oils for Biofuels Solutions for Your TOUGHEST MIXING Applications in THE FIRST NAME IN HIGH SHEAR MIXERS. There is considerable growth in the use of vegetable oils such as palm, rape seed, soybean, sunflower, etc. as an alternative to petroleum based diesels. Currently

Get Price

the caustic/oil mixer. 4. the retention mixers. 5. the primary centrifuge. 6. the wash water treatment system. 7. the water wash centrifuge. 8. the vacuum dryer for refined oil. New Developments Offer Significant Changes in Vegetable Oil Refining. In the last 20 years, there have been new developments in the way that vegetable oils are refined.

Get Price

Biofuel Industry Case Study: Refining of Vegetable Oils for Biofuels 1. Refining of Vegetable Oils for Biofuels The Advantages Introduction The Process The Problem The Solution HIGH SHEAR MIXERS/EMULSIFIERS CHEMICALS Solutions for Your TOUGHEST MIXING Applications in APPLICATION REPORT

Get Price

The neutral oil is washed in order to further reduce the residual soap content. For this purpose, approximately 3 10% of hot water is added to the oil, mixed in a dynamic mixer and separated into wash water and oil in a separator. The residual humidity of the oil is further reduced in a vacuum drier. 4.2. Miscella refining

Get Price

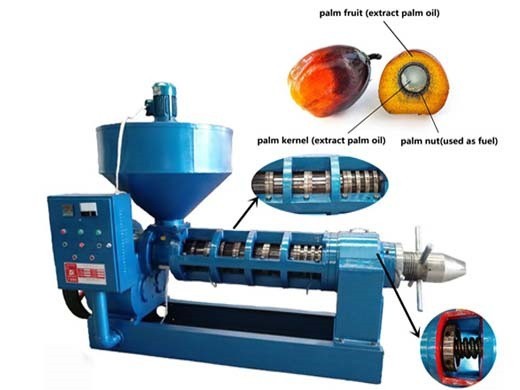

High Shear Mixers for Edible Oils. Edible oils may be extracted from a variety of plant or animal sources and are commonly found in the foods we eat. This report will focus on plant derived oils. These oils include the following examples: cottonseed oil, palm oil, peanut oil, soybean oil, sunflower oil, and linseed oil.

Get Price

The oil is transferred to a vacuum dryer for drying. The free fatty acids and other impurities (sugars, pigments and trace metals) separated from the oil are sent for downstream for processing into soapstock. Alfa Laval also offers neutralization systems for miscella refining of cottonseed oil as well as cold refining of sunflower or maize/corn germ ...

Get Price

refining or degumming, and prepares the oil for the final deodorization process. In the case of crude palm oil, bleaching is the initial stage of the whole refining process. At first glance, bleaching seems a relatively simple process that consists of mixing the oil with a powder, stirring for some minutes and then removing the powder again.

Get Price

One of the key steps in the refining process is the elimination of impurities from crude vegetable oils especially the phosphatides or so-called gums (see chapter Degumming - Introduction for their structural formulae). They are mainly present in oils extracted with solvent from soya beans, sunflower seed and rapeseed.

Get Price

Refining of Vegetable Oils for Biofuels View PDF There is considerable growth in the use of vegetable oils such as palm, rape seed, soybean, sunflower, etc. as an alternative to petroleum based diesels.

Get Price

Physical refining of soybean oil and canola oil is much more challenging, as these oils have the highest level of P, and can have the highest level of NHPs of all vegetable oils. EMI and Desmet installed physical refineries for soybean oil in Mexico and South America nearly 35 years ago.

Get Price

Mixing Applications. Through years of experience working with high shear mixers in many, many applications, Silverson has gained a wealth of mixing information.

Get Price

Multiple choice for fats and oils refining Alfa Laval degumming and neutralization solutions. Crude fats and oils always contain impurities that have to be removed and there is a growing focus on the environmental parameters for how you do it. Alfa Laval degumming and neutralization equipment is designed to work with virtually all types of fats and oils, making it one of the most efficient

Get Price

Bleaching. Bleaching fats and vegetable oils is a part of comprehensive refining technology. The natural colour of fats comes from chlorophyll and from carotenes or lipochromes. The partial bleaching of oil occurs in degumming, but it is not sufficient and therefore bleaching based on the affinity of pigment dissolved or dispersed in oil to the

Get Price

One of the key steps in the refining process is the elimination of impurities from crude vegetable oils especially the phosphatides or so-called gums (see chapter Degumming Introduction for their structural formulae). They are mainly present in oils extracted with solvent from soya beans, sunflower seed and

Get Price

The oil is transferred to a vacuum dryer for drying. The free fatty acids and other impurities (sugars, pigments and trace metals) separated from the oil are sent for downstream for processing into soapstock. Alfa Laval also offers neutralization systems for miscella refining of cottonseed oil as well as cold refining of sunflower or maize/corn germ

Get Price

Biofuel Industry Case Study: Refining of Vegetable Oils for Biofuels 1. Refining of Vegetable Oils for Biofuels The Advantages Introduction The Process The Problem The Solution HIGH SHEAR MIXERS/EMULSIFIERS CHEMICALS Solutions for Your TOUGHEST MIXING Applications in APPLICATION REPORT

Get Price

The neutral oil is washed in order to further reduce the residual soap content. For this purpose, approximately 3 10% of hot water is added to the oil, mixed in a dynamic mixer and separated into wash water and oil in a separator. The residual humidity of the oil is further reduced in a vacuum drier. 4.2. Miscella refining

Get Price

22.11.2025· Silverson In-Line mixers are used throughout the world for the refining of edible oils. Degumming and neutralisation is typically a high volume, continuous operation. The reagent additions are a

Get Price

The invention relates generally to methods of refining a renewable oil, such as a biofuel. In some embodiments, the invention relates to methods for the efficient removal of gums and waxes from a renewable oil.

Get Price

Winterization dewaxing. Winterization is a thermo-mechanical process in which solids are crystallized under controlled temperature conditions. The next stage is their mechanical separation. The process is used for oils that produce turbidity below 5°C, such as cotton and sunflower oil.

Get Price

Basics of Alkali Refining of Vegetable Oils Renato Dorsa Klaus-Peter Eickhoff Mechanical Separation Division Westfalia Separator Food Tec GmbH . 2 Objectives of Refining 1. Removal of undesired products from crude oils free fatty acids (FFA) phospholipids (gums) oxidised products metal ions colour pigments others 2. Preservation of valuable vitam铆nes. (vitamina E or

Get Price

Refining of vegetable oils is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (F. F.A.) from the oil; to impart uniform colour by removal of colouring pigments and to get rid of unpleasant smell from the oil by Online Chat Send Inquiry; Vegetable Oil Mill Plant, Vegetable Oil Extraction Section

Get Price

This invention relates to a process of refining animal and vegetable oils and more particularly to a process in which the mixture of oil and foots, produced by adding a refining reagent to the oil, is treated to remove volatile and gaseous materials prior to separating the foots from the oil.

Get Price

Process Description of Vegetable Oil Refining is as follows. Water Degumming : Water Degumming is first step in the Edible Oil Refinery Process.Oils contains Hydratable Phosphatide which absorb the water, that Hydratable Phosphatides are oil- insoluble which easily separated by centrifuge.

Get Price

US2702813A US275037A US27503752A US2702813A US 2702813 A US2702813 A US 2702813A US 275037 A US275037 A US 275037A US 27503752 A US27503752 A US 27503752A US 2702813 A US2702813 A US 2702813A Authority US United States Prior art keywords oil refining mixture phosphoric acid crude Prior art date 1952-03-05 Legal status (The legal status is an assumption and

Get Price

vegetable oils, i.e., margarines and shortenings. These factors have lead to development of technological processes for treatment of crude oils to make them as bland and colorless as possible and for modification of the physical characteristics of the oils. The refining techniques consist of water or acid degumming, alkali refining, bleaching and

Get Price

of oil also destroys essential fatty acids and produces toxic com-pounds and oxidized polymers.Oxidation of oil is very important in terms of palatability, nutritional quality, and toxicity of edible oils. Different chemical mechanisms, autoxidation and photosensi-tized oxidation, are responsible for the oxidation of edible oils during processing and storage depending upon the types of oxy-gen

Get Price

The oil normally becomes cloudy in 5h but with proper dewaxing the oil remains clear after 24h of storage at 0藲C. The following steps are used to dewax sun铿俹wer oil: Crude oil is re铿乶ed and bleached to low phosphorus (<1ppm) and low moisture content (<0.1%). The oil is heated to 55藲C to make sure the oil

Get Price

vegetable oils, i.e., margarines and shortenings. These factors have lead to development of technological processes for treatment of crude oils to make them as bland and colorless as possible and for modification of the physical characteristics of the oils. The refining techniques consist of water or acid degumming, alkali refining, bleaching and

Get Price

General speaking,there are two refinery methods,they are phycial refinery,physical and chemical combination refinery method. Physical refinery includes sediment method through utilizing different specific gravity, filtering ,centrifugal et...

Get Price

vegetable oil are oleic acid, linoleic acid and linolenic acid containing one, two and three double bonds between two carbon atoms respectively. The functionality present in vegetable oil is in terms of double bonds thus the C=C acts as a reaction site for chemical modification in vegetable oil[7].

Get Price

of oil also destroys essential fatty acids and produces toxic com-pounds and oxidized polymers.Oxidation of oil is very important in terms of palatability, nutritional quality, and toxicity of edible oils. Different chemical mechanisms, autoxidation and photosensi-tized oxidation, are responsible for the oxidation of edible oils during processing and storage depending upon the types of oxy-gen

Get Price

for the oil mill operator to minimize the contaminants even on recovering the crude palm oil and for the refiner, integrated into the respective refining process. Our decades of experience in the recovery and refining of vegetable oils can be found in both variants. Palm oil production worldwide: regions Your advantages

Get Price

.Study of refining wastewater pollution: case of vegetable oil refining industry Morocco M. Chatoui *¹, S. Lahsaini 1, S. Souabi ¹, M. A. Bahlaoui ¹, S. Hobaizi ¹, A. Pala² ¹ Laboratory of Water Engineering and Environment, Faculty of Sciences and Technologies, Hassan II Casablanca University, BP 146, Mohammedia, Morocco,

Get Price

Refining processes varies according to oil to be processed as different oil contains different type of impurities. After expelling/extraction, oil is processed through three main stages 1} Neutralization : to remove free fatty acids and other impu...

Get Price

One of the key steps in the refining process is the elimination of impurities from crude vegetable oils especially the phosphatides or so-called gums (see chapter Degumming Introduction for their structural formulae). They are mainly present in oils extracted with solvent from soya beans, sunflower seed and

Get Price

Deodorization is the final step in the refining of vegetable oils. Pressurize steam at extremely high temps (500 degrees or more) is used to remove volatile compounds that would cause off-odors and tastes in the final product.The oil produced is referred to as efined oiland is ready to be consumed or for the manufacture of other products.

Get Price