More Related Industries. Foods Chocolate liquor Frying oil Potato starch Protein from yeast slurry Soymilk Chemicals Aluminium paint suspension Centrifuges Classify pigments Feeds to decanters Minerals Calcium carbonate Colombian ore in closed circuit grinding Separate impurities from kaolin slurry prior to centrifuging Pulp and Paper Coating suspensions Recovering fiber from mill effluent ...

Microbial lipid accumulation through bioremediation of palm oil mill wastewater by Bacillus cereus Article (PDF Available) in ACS Sustainable Chemistry & Engineering · August 2025 with 92 Reads

Get Price

Palm oil mill effluent (POME) is wastewater generated from the palm oil milling process. It is regarded as a highly polluting wastewater as it has a high chemical oxygen demand (COD), and contains ...

Get Price

oil solids API separator effluent solids pre-treatment M pH acid / lye oily waste water floating layer water flotation water aeration tank effluent sludge water sewage sludge ® TECHNICAL INFO Oil and sewage sludge treatment with Flottweg Technology Flottweg Tricanter® System . 4 ® = registered trademark in various countries FLOTTWEG SEPARATION TECHNOLOGY High Quality Centrifuge Technology ...

Get Price

The electrocoagulation (EC) process is an electrochemical means of introducing coagulants and removing suspended solids, colloidal material, and metals, as well as other dissolved solids from water and wastewaters. The EC process has been successfully employed in removing pollutants, pesticides, and radionuclides. This process also removes harmful microorganisms. More often during EC operation ...

Get Price

Design of Table Top Electrocoagulation Unit for Remediation of Wastewater from Paper Industry - written by Siddharth Meshram , Laxmi Yergude , Piyush Amrutkar published on 2025/12/25 download full article with reference data and citations

Get Price

Immobilized Nannochloropsis sp. Mitigated >99% CO 2 in secondary POME (Palm Oil Mill Effluent) with concomitant lipid production of 0.35 gL −1 lipid production which was 1.41-fold higher when compared to the control (Cheirsilp et al., 2017).

Get Price

A new approach using coagulation rate constant for evaluation of turbidity removal. Post-treatment sludge analyses and purification of paint effluent by coag... Post-treatment sludge analyses and purification of paint effluent by coag-flocculation method. Perikinetics and sludge study for the decontamination of petroleum produced...

Get Price

Coagulation and electro-coagulation may be effective treatments for Palm Oil mill and Paint Wastewaters, as they are said to properly remove turbidity and decrease the level of suspended solids and also remove oil (Juntipa, 2009). Electrocoagulation is also known as radio frequency diathermy or short wave electrolysis.

Get Price

Palm oil mill effluent (POME) was pretreated to remove suspended solids and residual oil. The processes used were flocculation, solvent extraction, adsorption and membrane separation. Flocculation was used to remove suspended solids, and solvent extraction and adsorption processes were used to remove residual oil.

Get Price

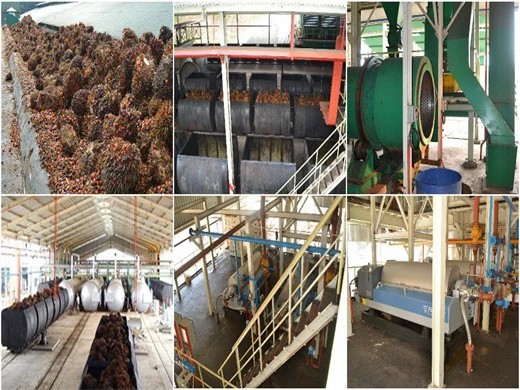

Palm oil mill effluent (POME) generated from palm oil milling processes to produce crude palm oil (CPO) is the most polluting agro-industrial effluent. It is estimated that 0.5–0.75 tonne of raw POME were produced for every tonne of fresh fruit bunches (FFB) processed (Yacob et al., 2006).

Get Price

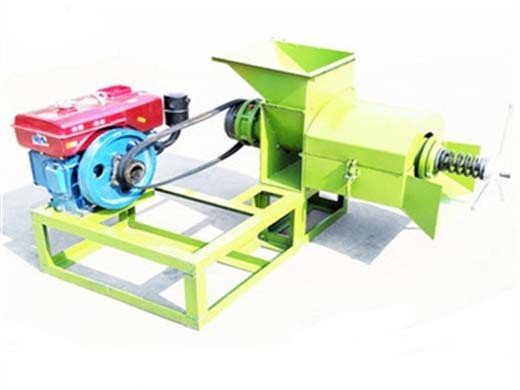

from the digested fruit mash by the use of the screw press Palm oil mill effluent (POME): Effluent water is defined without kernel breakage [4]. This palm oil production as water discharged from industry, which contains soluble process is shown on Fig. 1. materials that are injurious to the environment. Such

Get Price

A new effluent treatment scheme is proposed for treating palm oil mill effluent based on coagulation and anaerobic digestion of coagulated sludge. The effectiveness of anionic (N9901) and cationic (N9907) polyelectrolytes manufactured by NALCO (Malaysia) was evaluated both as coagulant and coagulant aid.

Get Price

Modeling BOD and COD removal from Palm Oil Mill Secondary Effluent in floating wetland by Chrysopogon thereby allowing for better biodegradation of organic solids. The high percentages removal for COD is caused by sedimentation of suspended solids and by decomposition processes CRC Press (2014) Google Scholar. Kadlec and Wallace

Get Price

2.2. Palm Oil Mill Effluent (POME) Raw POME sample was collected by grabbing a sample directly from the inlet of a waste stabilization pond which discharged from stone and sand filtration from local industry in Johor Bahru province in Malaysia.

Get Price

POME is the liquid waste generated from the oil extraction process from FFB in palm oil mills .Typical characteristics of POME are shown in Table 1.This effluent is a thick brownish liquid with high biochemical oxygen demand (BOD) and chemical oxygen demand (COD) .Furthermore, its high solids concentration and acidity causes it to be unsuitable for direct discharge to watercourses.

Get Price

Hence, it is suggested that a biodegradable coagulant can be a better alternative. Coagulation of residue oil and suspended solid from palm oil mill effluent (POME) an oily effluent using a biodegradable biopolymer, i.e. chitosan was explored in this study using a flocculator.

Get Price

15-7-2015· Abstract. The present study investigates the removal efficiency of chemical oxygen demand (COD) and total suspended solids (TSS) of anaerobically digested palm oil mill effluent in batch studies through the following 4 strategies: coagulation by chitosan, addition of ferrous sulphate (FeSO 4), chitosan with hydrogen peroxide (H 2 O 2) and chitosan with Fenton oxidation.

Get Price

Abstract. The present study investigates the removal efficiency of chemical oxygen demand (COD) and total suspended solids (TSS) of anaerobically digested palm oil mill effluent in batch studies through the following 4 strategies: coagulation by chitosan, addition of ferrous sulphate (FeSO 4), chitosan with hydrogen peroxide (H 2 O 2) and chitosan with Fenton oxidation.

Get Price

RESOURCE RECOVERY AND CDM PROFIT FROM PALM OIL MILL RESOURCE RECOVERY AND CDM PROFIT FRO M PA 98.7% suspended solids removal and 54% chemical oxygen demand removal with a dosage

Get Price

Palm Oil Mill Effluent (POME) Tertiary/Polishing Treatment Plant . Researcher: Pn. Noorshamsiana Abd. Wahab / Cik Nor Faizah Jailani . Under 10th Malaysian Plan (RMK-10) budget, an integrated system of palm oil mill effluent (POME) tertiary pilot plant was setup with the objective to comply with the 20 ppm BOD of the final discharge.

Get Price

This journal publishes papers that aid in the development, demonstration, and commercialization of cleaner products and processes as well as effective environmental policy strategies. As its title suggests, the journal has two major thrusts: Clean Technologies and Environmental Policy.

Get Price

water through the filter media, leaving the solids behind. Today most sludge dewatering uses a filter press with membrane plate to produce a high solids filter cake. Palm oil milling generates large volumes of effluent with 3%-4% suspended solids. Dis-charging all the undigested solids into the treatment pond can overhelm the bacterial activity,

Get Price

4.2 PALM OIL MILL EFFLUENT (POME) Palm oil mill effluent originates from two main processes: sterilization and clarification stages, higher level of solid residues compared to the sterilizer condensate. Both contain some level of unrecovered oils and fats. The final POME would of course include hydrocyclone washing and

Get Price

28-3-2020· Wastewater treatment Wastewater treatment Sludge treatment and disposal: The residue that accumulates in sewage treatment plants is called sludge (or biosolids). Sewage sludge is the solid, semisolid, or slurry residual material that is produced as a by-product of wastewater treatment processes. This residue is commonly classified as primary and secondary sludge. Primary sludge is

Get Price

MPOB INFORMATION SERIES • ISSN 1511-7871 • JUNE 2006 MPOB TT No. 335 MOBILE FILTER PRESS FOR EFFLUENT POND CLEANING 340 T Malaysian Palm Oil Board, Ministry of Plantation Industries and Commodities, Malaysia

Get Price

POME Palm Oil Mill Effluent. Looking for abbreviations time, pH, and temperature) affect electrocoagulation of Palm Oil Mill Effluent (POME) and Paint Wastewater (PW) using only iron electrode. Removal of Solids from Palm Oil Mill Effluent and Paint Wastewater Using Electrocoagulation Technique. Chong, "Development of anaerobic digestion

Get Price

Synonyms for pome in Free Thesaurus. Antonyms for pome. 1 synonym for pome: false fruit. What are synonyms for pome?

Get Price

Removal of Solids from Palm Oil Mill Effluent and Paint Wastewater Using Electrocoagulation Technique Use of glacial acetic acid to enhance bisexual monitoring of tortricid pests with kairomone lures in pome fruits.

Get Price

29-8-2016· The aim of this work was to study the treatment of Palm Oil Mill Effluent (POME) and Paint Wastewater (PW) by coagulation and electrocoagulation processes. Coagulation was carried out using Mucuna shell coagulant and electrocoagulation was carried out using two Iron electrodes.

Get Price

Removal of Solids from Palm Oil Mill Effluent and Paint Wastewater Using Electrocoagulation Technique. Considering all parameters with their range, the predicted maximum COD removal from AT- POME by an aerated heterogeneous sono-Fenton process was 93.17 % as shown in Fig. Removal of COD from palm oil mill effluent

Get Price

Palm oil processing operation is invariably accompanied by palm oil mill effluent (POME) considered to be an environmental pollutant. While anaerobic digestion and the present tertiary treatment technologies of POME are able to meet the current regulatory effluent discharge requirement of biological oxygen demand (BOD) 100 mg litre-1 the current limit set by the Department of Environment

Get Price

Vacuum dryer functions to remove moisture from the crude palm oil. High moisture content of the purified oil will preclude a further set up of FFA content during storage and shipment. The oil must be further dried to a final moisture content of below 0.20% which is the final step in the oil recovery process.

Get Price

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

Get Price

Solid Separation from Sludge Using Membrane Filter Press Crude Palm Oil Clarification by Cyclo-seperator and Filter Press System Fibre Washing Using a Dynamic Washer Mobile Filter Press for Effluent Pond Cleaning Water Cooled Screw Press for Production of Feed Quality Palm Kernel Expeller (PKE) for Feedstuff Plant-wide Automation of Palm Oil

Get Price

Palm Oil Mill Operation, processing and process,production quality control, effluent disposals and maintenance course OBJECTIVES To acquire overall broad knowledge of fundamentals and practices of palm oil FFB grading and analysis, mill productions, operations, managements and

Get Price

Processing facilities Palm oil mill and palm kernel crushing process: a brief description . Fresh fruit bunches (FFB) from the plantations are offloaded daily at the factory's offloading bay. This ramp can contain up to 600 tonnes of FFB. Before offloading, the fruit is weighed at the electronic weighbridge at the entrance gate.

Get Price