conventional methods that rely on frozen crystals dewaxing, then separated by mechanical means oil, wax, without adding any auxiliary agents and auxiliary means dewaxing processes. Conventional bag filter separation, pressure filtration, vacuum filtration and centrifugation methods.

This process (Cavanagh, 1974) separated > 90% of rice bran Waxes miscella phase dewaxing is a well-known process in Japan as the solvent plants are quite large. In addition, miscella dewaxing also depends on the oil content in the miscella, operating temperature, and inclusion of additives (calcium chloride, etc.).

Get Price

Oil refining is according to the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude oil, getting standard oil . 4.Rice Bran Oil Dewaxing: Dewaxing means by use refrigerating unit,to remove wax from the oil. Main equipment introduction

Get Price

The Process of Rice Bran Oil Production Line. Section I. Pretreatment & Expanding; ... The crude rice bran oil from the extraction workshop is pumped into the crude oil filter to remove the residual impurities and then enters the heat exchanger and heater to be heated to the desired temperature. ... Dewaxing. Crude rice bran oil usually ...

Get Price

Easy to filter,,the product oil has high yield 3 Pure by-product edible wax,not contain filter aid agent and can use the edible wax production directly,no pollution. Main operation . Crystallizing Process . Filtering process . Part of rice bran de waxing plant

Get Price

Cooking Oil Dewaxing Process Common Raw Oil for Dewaxing, Winterization:. Sunflower oil, corn germ oil, rice bran oil, cottonseed oil and so on. Main Steps of Oil Dewaxing Process. Conventional dewaxing is the common oil dewaxing method with the working principle of freezing and then mechanically separating oil & wax without any auxiliary means, the separating methods are usually pressure ...

Get Price

Rice bran oil dewaxing process: ... oil will be filtered by vibrating filter. Better to use two filters alternately to keep continuous working. ... .,Ltd is a leading manufacturer specialized in cooking oil making machine with capacity 10-2000TPD.We can offer cooking oil press machine,oil extraction machine,oil refinery & fractionation plant.

Get Price

Often Called as Winterization Process Post Cooling. Dewaxing may be the fifth process considered for the edible oil refining. It is not a compulsory process and it is not required for every type of oil. Dewaxing is performed only for high wax containing oils such as Sunflower Oil, Rice Bran Oil, Corn Oil etc.

Get Price

Winterization of oil is a process of removing of the higher melting point parts from oil like waxes or triglycerides. It is also a process of removing components with high melting point (e.g waxes) from some vegetable oils, e.g. sunflower, rice bran and cotton seed oil or partially hydrogenated soya bean oil.

Get Price

conventional methods that rely on frozen crystals dewaxing, then separated by mechanical means oil, wax, without adding any auxiliary agents and auxiliary means dewaxing processes. Conventional bag filter separation, pressure filtration, vacuum filtration and centrifugation methods.

Get Price

offers 208 dewaxing process products. About 40% of these are oil pressers, 1% are machining, and 1% are lubricant. A wide variety of dewaxing process options are available to you, such as haccp, iso, and fda.

Get Price

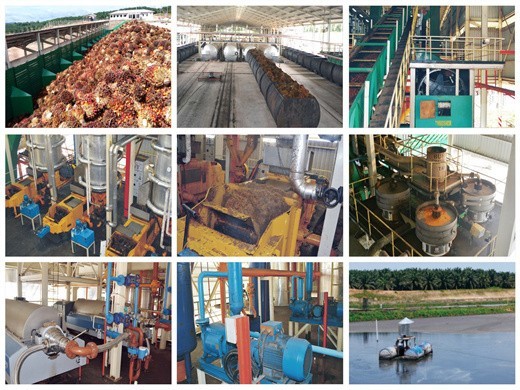

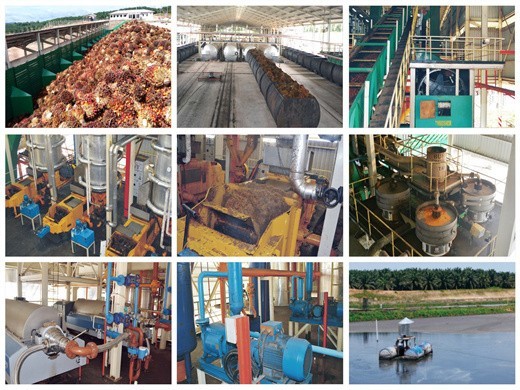

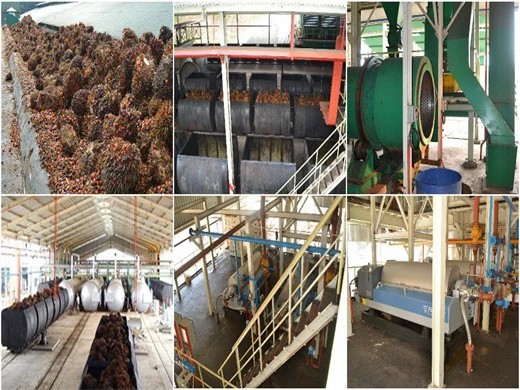

Rice Bran Oil Extraction Plant Introduction. Rice bran oil extraction plant produces rice bran oil using expansion extraction technology.The rice bran oil plant includes rice bran pretreatment & expanding workshop, rice bran oil solvent extraction workshop and rice bran oil refining workshop.

Get Price

A wide variety of dewaxing filter options are available to you, There are 216 suppliers who sells dewaxing filter on, mainly located in Asia. The top countries of suppliers are India, China, from which the percentage of dewaxing filter supply is 1%, 99% respectively.

Get Price

06.12.2017· Cooking Oil Dewaxing Process Common Raw Oil for Dewaxing, Winterization:. Sunflower oil, corn germ oil, rice bran oil, cottonseed oil and so on. Main Steps of Oil Dewaxing Process. Conventional dewaxing is the common oil dewaxing method with the working principle of freezing and then mechanically separating oil & wax without any auxiliary means, the separating methods are usually

Get Price

Find details of companies offering rice bran oil equipment at best price. Listed manufacturers, suppliers, dealers & exporters are offering best deals for rice bran oil equipment.

Get Price

Winterization of oil is a process of removing of the higher melting point parts from oil like waxes or triglycerides. It is also a process of removing components with high melting point (e.g waxes) from some vegetable oils, e.g. sunflower, rice bran and cotton seed oil or partially hydrogenated soya bean oil.

Get Price

5. Filter Section: Adopting advanced diaphragm filter system, the main difference between the diaphragm filter press and the common chamber filter press is the addition of a semi-automatic diaphragm filter press between the filter plate and the filter cloth composite rubber plate elastic diaphragm membrane plate . During the operation, when

Get Price

The advanced refinery technologies from Germany and Belgium have been used at the refining process. Every process is closely monitored resulting in High Oryzanol Rice Bran Oil that is suitable for healthy cooking as well as cosmetics and spa products.

Get Price

Crude rice bran oil exits from last evaporator is cleaned by screen and sent to storage tanks. Refining process. Crude rice bran is passed these processes to become refined rice bran oil: Degumming and neutralization: using Alfa-Laval Separators. Bleaching: using filter leaves. Deodorizing: using superheat steam as heating media. Dewaxing; Bottling

Get Price

The refining method of rice bran oil refinery plant hemical refinery hysical refinery hemical &physical combination refinery. Working process of rice bran oil refinery plant:. 1.Pump crude edible oil into refining tank and heat with conduction oil, and the

Get Price

In the pressing process, SZY type screw oil press is specially selected, this machine is specially designed with a large theoretical compression ratio, so the oil can be pressed and expanded many times in the press chamber to realize the strong pressing, and the oil yield is high in one press.

Get Price

Raw material (rice bran) 鈫抦agnetic separation 鈫抐loury product separation 鈫抭uenching and tempering 鈫抪uffing(extrusion machine)鈫抎rying and cooling 鈫抯olvent extraction plant 鈫抮efining plant 鈫抎ewaxing plant 鈫抙igh quality refined oil. The brief introduction of rice bran oil processing plants: a. Pretreatment plant makes the rice

Get Price

This study investigated the physicochemical and antioxidant properties of rice bran oil (RBO) produced from the bran of three rice varities; Khao Dawk Mali 105 (white rice), Red Jasmine rice (red

Get Price

Palm oil fractionation Palm oil franctionation is a new item of oil processing technology, palm oil franctionation process can get different melting point of palm oil products with 8 鈩? 10 鈩? 14 鈩? 18 鈩? 24 鈩? 33 鈩? 44鈩? 55鈩? etc. while also can used to processing cottonseed oi

Get Price

The edible grade rice bran oil is a crude oil and it will be refined in the refinery. The Deoiled Bran will be sold as it is for fish farms, poultries and also for exports. It is estimated that about 60 Units of Power and 500 Kgs of steam are required to process one ton of rice bran in solvent extraction.

Get Price

Oil that is processed through the refinery is light in color and known for its excellent quality. During the processing of oil, we filter out the fatty acids present in oil, so that it can match up to the grade of edible oil. Besides, dewaxing process is carried out for rice bran oil and sunflower oil, in

Get Price

Chapter 5 : Processing and refining edible oils. Contents Previous Next. Rural vegetable oil production Large-scale production Potential side reactions during high-temperature processing Physical losses Fat modification processes Other considerations Conclusions. Processing can remove the components of edible oils which may have negative effects on taste, stability, appearance or

Get Price

Find here LD Oil Refining Dewaxing Equipment manufacturers, suppliers & exporters in china. Get contact details & address of companies manufacturing and supplying Auxiliary Machine For Oil Press across

Get Price

Dewaxing equipment of rice bran oil refinery plant. 5. Dewaxing: Through crystallization, cooling and filtration, the wax will be removed from rice bran oil. After that, rice bran oil will be filtered once again through safety filter, then it is sent to oil storage tanks. Types of rice bran oil refinery plant: Batch type, 1-2-3-5-10TPD. Semi

Get Price

The edible grade rice bran oil is a crude oil and it will be refined in the refinery. The Deoiled Bran will be sold as it is for fish farms, poultries and also for exports. It is estimated that about 60 Units of Power and 500 Kgs of steam are required to process one ton of rice bran in solvent extraction.

Get Price

An indigenously developed low-cost clay-alu-mina-based ceramic microfiltration membrane of 19-channel configuration has been evaluated for degumming, dewaxing and deacidification of rice bran oil (RBO) miscella having different oil contents at pilot

Get Price

The brans have not been stabilized as the frozen condition during storage could minimize all enzyme activities and de-teriorations20 2.2 Extractions and re藴ning processes For CPE, the rice bran was fed continuously into the hopper of a 2-HP screw press extractor. The crude oil was forced through the slits along the barrel length. The com-

Get Price

In a typical screw press, the feed material fed at the one end of the screw shaft and the De-oiled cake/Press Cake is collected the opposite end of the screw shaft, as the feed material travels in the annular space between screw shaft and perforated oil chamber, the oil seeds are subjected to high mechanical pressure which results in rupture of the oil cells.

Get Price

China Vegetable Oil Press manufacturers Select 2020 high quality Vegetable Oil Press products in best price from certified Chinese Oil Machine manufacturers, Oil Press suppliers, wholesalers and factory on Made-in-China

Get Price

Plate and Frame Filter Press Compatible with Oil Extraction Machine: Advanced Oilseed Roasting Machine for Sale: Oilseed Cleaning Machine for Seeds, Beans and Grains: Screw Extruder for Soybean and Rice Bran in Cereal and Oil Industry: Plate and Frame Filter Press Compatible with Oil

Get Price

Rice Bran is obtained from the granular coating between the rice kernel and the husk, known as the hull. The crude rice bran oil, subsequently undergoes the following rice bran oil refining process before it is bottled: degumming and neutralization, bleaching, deodorizing, dewaxing, cold filtering (winterisation) and packaging.. Rice Bran Oil Refining Process

Get Price

Refinery process mainly includes: Drying, degumming, deacidification, decolorization, deodorization, dewaxing, degreasing. After refining, press oil can meet the

Get Price

Dewaxing equipment of rice bran oil refinery plant. 5. Dewaxing: Through crystallization, cooling and filtration, the wax will be removed from rice bran oil. After that, rice bran oil will be filtered once again through safety filter, then it is sent to oil storage tanks. Types of rice bran oil refinery plant: Batch type, 1-2-3-5-10TPD. Semi

Get Price

Rice bran is a mixture of substances, including protein, fat, ash, and crude fiber, inside which, the oil content in rice bran is 10鈭?3%. Rice bran and rice bran oil Rice bran oil is known for its high smoke point of 232 °C (450 °F) and mild flavor, making it suitable for high-temperature cooking methods such as stir frying and deep frying.

Get Price