Soybean seed processing flow chart shows how the seed is processed to make oil from Seed of the Soybean. Leading manufacturer of Oil Screw Press. Edible Oil Refinery Plant; Solvent Extraction Plant; Animal Feed Plant; Material Handling Equipments; Oil Neutralizer Soybean Oil Manufacturing Process Flowchart. Call Us: +91 98140 33180 10

In comparison, solvent extraction with hexane (the primary solvent used worldwide) will remove all but about 陆% of residual oil, uses less horse power, and requires less maintenance. It is relatively efficient and reliable, and this is one reason why solvent extraction is the primary means of separating large tonnages of oil from protein meal.

Get Price

Iwanaga, Gray, Fisk, Decker, Weiss and McClements Abstract: Soybeans contain oil bodies that are coated by a layer of oleosin proteins. In nature, this protein coating protects the oil bodies from environmental stresses and may be utilized by food manufacturers for the same purpose.

Get Price

Soybean Oil Extraction. Commercial soybean oil extraction is a complex process. The traditional method for soybean oil extraction was a mechanical process using hydraulic presses. Because it was expensive and produced lower yields, the mechanical production process has given way to production by means of extraction with solvents.

Get Price

to the solvent-extraction process, which removes more oil from the soybean. Today, more than 99 percent of the U.S. processing capacity is using the solvent extraction process. U.S. soybean meal is produced in large crushing facilities that produce meals of consistent high quality. Several of these plants process more than 3,000 tons per day.

Get Price

The soybeans are also heated to about 75掳C to coagulate the soy proteins to make the oil extraction easier. Extraction Section of Soybean Oil Production: First the soybeans are cut in flakes which are put in a percolation extractors and immerged with a solvent, normally hexane. Counterflow is used as extraction system because it gives the highest yield. After removing the hexane, the extracted flakes only contain about 1% of soybean oil and is used as livestock meal or to produce food

Get Price

Using solvent extraction process to make soybean oil is very popular. If you want to manufacture soybean oil by solvent extraction method, the input capacity of soybeans each day had better more than 30 tons, for the cost of soybean oil solvent extraction machine is higher than soybean oil press machine.

Get Price

SOLVENT EXTRACTION OF OIL FROM SOYBEANS

Get Price

Soybean Oil Solvent Extracting Process. The pretreated soybean flakes are sent to the soybean solvent extraction plant. The plant uses a kind of solvent (normal hexane) to absorb the oil from soybean, and then the machines separate the solvent from soybean crude oil.

Get Price

The use of biodiesel as co-solvent of ethanol for obtaining soybean oil seems promising in the sense of lowering the energy required to the process, wherein its effect becomes higher at lower temperatures. Furthermore, our results showed the technical viability of soybean oil extraction using ethanol with biodiesel a co-solvent.

Get Price

50TPD Soybean Solvent Extraction Plant,US $ 50,000 - 80,000 / Set, New, Peanut Oil, Oil Solvent Extraction for Cake, Soybean Solvent Extraction Plant, Send Inquiry; 10-50TPD soybean processing oil plant with low cost . 10-50TPD soybean processing oil plant with low cost manufacturers, suppliers & exporters in china.

Get Price

Seed oils represent 70% of global oil production, of which 30% is soybean oil. Oilseeds are the most important export items in Argentina.. In oilseeds, the vacuoles within cells contain oil, and both cell walls and vacuoles have to be broken in order to improve solvent extraction.

Get Price

to the solvent-extraction process, which removes more oil from the soybean. Today, more than 99 percent of the U.S. processing capacity is using the solvent extraction process. U.S. soybean meal is produced in large crushing facilities that produce meals of consistent high quality. Several of these plants process more than 3,000 tons per day.

Get Price

The extraction process uses hexane or other solvents to wash the soybean oil from the prepared soybean flakes. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the contact time of the solvent and flakes, and the power and utilities needed to run the

Get Price

Soybean Oil Solvent Extracting Process. The pretreated soybean flakes are sent to the soybean solvent extraction plant. The plant uses a kind of solvent (normal hexane) to absorb the oil from soybean, and then the machines separate the solvent from soybean crude oil.

Get Price

Using solvent extraction process to make soybean oil is very popular. If you want to manufacture soybean oil by solvent extraction method, the input capacity of soybeans each day had better more than 30 tons, for the cost of soybean oil solvent extraction machine is higher than soybean oil press machine.

Get Price

Seed oils represent 70% of global oil production, of which 30% is soybean oil. Oilseeds are the most important export items in Argentina.. In oilseeds, the vacuoles within cells contain oil, and both cell walls and vacuoles have to be broken in order to improve solvent extraction.

Get Price

Process of soybean oil extraction. 2017-10-09 16:54; Oil solvent extraction process; Chat Online; Get price; Soybean is the most common oil seed in the world, usually soybean oil extraction is one time oil extraction, that is, soybean seeds goes directly to oil extraction after soybean pretreatment without pressing, because soybean oil contain is low.

Get Price

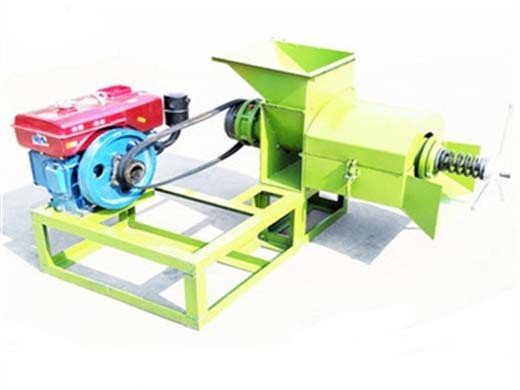

A complete oil processing line (oil plant) generally includes expeller process and solvent extraction process. You are welcome to send us an email for more details of our oil plant. Mechanical Pressing Process(screw-press) Expeller is the key equipment of screw-press process, which is also known as screw oil press.

Get Price

Soybean oil processing machine - Edible oil extraction machine. The soybean oil solvent extraction plant is part of soybean oil processing machine which is designed to extract oil directly from pressed soybean cake. After soybean oil solvent extraction plant , the residual oil rate in soybean cake is less than 1%. Get Price

Get Price

But the temperature should not be higher than the boiling point of solvent to avoid the solvent evaporation. Thus, the material temperature should be controlled in 45 ~ 55掳C. It should not be more than 60掳C. We are great supplier of soybean oil extraction and related oil refinery equipment. Contact us to get more info with soybean oil plant.

Get Price

for enriching cereal diet. The primary processing of soybean before oil extraction include cleaning, cracking, flaking and conditioning, these ruptures the oil cells, for efficient extraction. Most modern oil extraction industries use the solvent extraction process and the solvent commonly used is the food grade hexane.

Get Price

Soybean oil solvent extraction plant for sale, The soybean oil solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean flaking or it extracts oils from prepressed or fully pressed cake.

Get Price

Due to the high oil yield of solvent extraction, most of the soybean oil and cottonseed oil are processed and manufactured by using the "No.6 light gasoline" extracting method. 2. Different nutrients The pressed soybean oil is good in color, aroma and taste and retains various nutrients. While the solvent extracted oil is colorless and tasteless.

Get Price

The aim of this work was to study the removal of free fatty acids (FFAs) from soybean oil, combining solvent extraction (liquid-liquid) for the separation of FFAs from the oil and membrane technology to recover the solvent through nanofiltration (NF). Degummed soybean oil containing 1.05 卤 0.10% w/w FFAs was deacidified by extraction with ethanol.

Get Price

for enriching cereal diet. The primary processing of soybean before oil extraction include cleaning, cracking, flaking and conditioning, these ruptures the oil cells, for efficient extraction. Most modern oil extraction industries use the solvent extraction process and the solvent commonly used is the food grade hexane.

Get Price

Process of soybean oil extraction. 2017-10-09 16:54; Oil solvent extraction process; Chat Online; Get price; Soybean is the most common oil seed in the world, usually soybean oil extraction is one time oil extraction, that is, soybean seeds goes directly to oil extraction after soybean pretreatment without pressing, because soybean oil contain is low.

Get Price

Soybean extraction meal comprises residues arising from oil extraction from soybeans performed using an extraction solvent. The starting materials for this solvent extraction process are oil seeds with a low oil content or expeller pulp produced by previous cold or hot pressing (Manufacture of vegetable pressing residues). The oil is extracted

Get Price

Soybean seed processing flow chart shows how the seed is processed to make oil from Seed of the Soybean. Leading manufacturer of Oil Screw Press. Edible Oil Refinery Plant; Solvent Extraction Plant; Animal Feed Plant; Material Handling Equipments; Oil Neutralizer Soybean Oil Manufacturing Process Flowchart. Call Us: +91 98140 33180 10

Get Price

Soybean Oil Extraction Process by Solvent Extraction. The first step is cleaning the soy seeds. Then, dry the seeds and dehull prior to oil extraction. You have to remove the soybean hulls because they absorb oil and give a lower yield. However, you can dehull by cracking the soybeans. Finally, separate the hulls and cracked soybeans mechanically.

Get Price

Soybean oil production line consists of soybean pretreatment process, soybean oil solvent extracting process and soybean crude oil refining process.

Get Price

The purpose of this study is to evaluate multienzyme hydrolysis as a pretreatment option to improve soybean oil solvent extraction and its eventual adaptation to conventional processes. Enzymatic action causes the degradation of the cell structures that contain oil. Improvements in terms of extraction, yield, and extraction rate are expected to be achieved. Soybean flakes and collets were used

Get Price

Soybean seeds contain 18% to 20% oil. Normally soya bean seeds are not subjected to mechanical pressing but the entire oil is extracted after preparation of the seeds in the solvent and Soybean Extraction Plant.

Get Price

A complete oil processing line (oil plant) generally includes expeller process and solvent extraction process. You are welcome to send us an email for more details of our oil plant. Mechanical Pressing Process(screw-press) Expeller is the key equipment of screw-press process, which is also known as screw oil press.

Get Price

Due to the high oil yield of solvent extraction, most of the soybean oil and cottonseed oil are processed and manufactured by using the "No.6 light gasoline" extracting method. 2. Different nutrients The pressed soybean oil is good in color, aroma and taste and retains various nutrients. While the solvent extracted oil is colorless and tasteless.

Get Price

Soybean Oil Extraction. Commercial soybean oil extraction is a complex process. The traditional method for soybean oil extraction was a mechanical process using hydraulic presses. Because it was expensive and produced lower yields, the mechanical production process has given way to production by means of extraction with solvents.

Get Price

Soybean extraction meal comprises residues arising from oil extraction from soybeans performed using an extraction solvent. The starting materials for this solvent extraction process are oil seeds with a low oil content or expeller pulp produced by previous cold or hot pressing (Manufacture of vegetable pressing residues). The oil is extracted

Get Price

Soybean seed processing flow chart shows how the seed is processed to make oil from Seed of the Soybean. Leading manufacturer of Oil Screw Press. Edible Oil Refinery Plant; Solvent Extraction Plant; Animal Feed Plant; Material Handling Equipments; Oil Neutralizer Soybean Oil Manufacturing Process Flowchart. Call Us: +91 98140 33180 10

Get Price