This is turnkey soybean oil mill project built in Zambia, including 6 sets of 2500T Storage Silo, 100 ton/day Soybean Preprocessing Plant, 100 ton/day Solvent Extraction Plant, 20 ton/day Refinery Plant, and 10 ton/day Animal Feed Plant.

ZAMBIA – Cargill has announced that it will cease all operations at its soybean processing and vegetable oil refinery plant in Lusaka, Zambia effective end of October.. The American based grain and agricultural corporation made the decision in regard to increasing amount of illegal imports of vegetable oil from neighbouring countries, a Lusaka Times report reveals.

Get Price

Soybean Oil Processing Plant in Zambia. So far we have helped set up a number of oil processing plants for different types of oil seeds over the world, the biggest one is the soybean oil processing plant in zambia. In this project, we have used advanced oil processing technology with various quality soybean oil processing equipment. Bellow are ...

Get Price

Machinery is the BEST soybean oil refinery plant machinery manufacturer in China, has exported top quality oil refining equipment for many countries, including Zambia, Russia, Jamaica, Ghana, Uzbekistan, etc.

Get Price

want to setup small soybean oil manufacturing plant Hello sir I am Anil maurya I am working as an engineer in automobile industry we are 4 friend want to start soybean oil plant so I want to know details of manufacturing process cost budget and machines are required please help me mail id contact 8379005109

Get Price

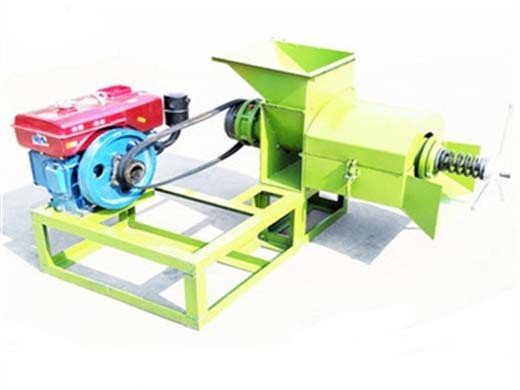

Engaged in oil machinery & oil mill project design, manufacturing, installation, commissioning. Guide you to choose suitable oil press machine, oil processing equipment from oil pretreatment, oil pre-pressing, oil solvent extraction to oil refinery based on your oilseeds, factory area and budget.

Get Price

Features of Soybean Oil Mill Plant: 1. High oil yeild & low waste 2. Stable performance 3. Unique design for each customer 4. Newest technology and automatic. Further Details of Soybean Oil Mill Plant: The whole Soybean Oil Mill Plant includes soybean pre-pressing workshop, solvent extraction workshop and crude. Send Inquiry

Get Price

The production of commercial soybean oil is complicated. Below are the main steps of the soybean oil production process. Cleaning Section of Soybean Oil Production: The soybeans are first cleaned, dried and dehulled prior to oil extraction. The soybean hulls needs to be removed because they absorb oil and give a lower yield. This de-hulling is ...

Get Price

Edible Oil Refining Process. The edible oil refining equipment Machinery provide is suitable for refining all kinds of crude vegetable edible oil, such as rice bran oil, peanut oil, soybean oil, sunflower oil, palm oil, palm kernel oil, cottonseed oil, olive oil, mustard oil, coconut oil, etc.

Get Price

This is one of the largest soybean oil mill built in Zambia. It is a turnkey soybean processing project including 6 sets of 2500T Storage Silo, 100 ton/day Soybean Preprocessing Plant, 100 ton/day Solvent Extraction Plant, 20 ton/day Refinery Plant, and 10 ton/day Animal Feed Plant.

Get Price

Soybean Oil Refining Processes. According to the different uses of soybean oil (food and non- food uses) the soybean oil refining process is different. The specifications of the R.B.D. will be more definite and difficult to obtain for the margarine industry, mainly for the Distributive Trade Market. Different Soybean Oil Refining Processes

Get Price

Soybean Oil Processing Plant in Zambia. So far we have helped set up a number of oil processing plants for different types of oil seeds over the world, the biggest one is the soybean oil processing plant in zambia. In this project, we have used advanced oil processing technology with various quality soybean oil processing equipment. Bellow are

Get Price

Soyabean Oil Refinery by Tinytech comes in various capacities ranging from entry level small scale plant of 5-TPD to medium and big scale plants upto 30-TPD. We are leading manufacturers and exporters of Soyabean Oil Refinery Plant systems for processing the crude soya oil into the refined soya oil. Refining technology means separating impurity

Get Price

Advanced techniques applied soybean oil refining production line with high efficiency and low residual oil.Henan Doing Comapny is focusing on designing physical and chemical edible oil refining process through de-mixed, degumming, dehydration, deacidification, decoloration, dewax and deodorization, oil pumps, filter system to obtain high purity refined soybean oil.

Get Price

Soybean oil refining process: 1. Hydration Degumming & Alkali Refining Deacidification Process Neutralization: The crude oil is output by the oil feed pump from the oil tank, and enters the crude oil heat exchanger to recover part of heat after metering and then is

Get Price

China Soybean Oil Refinery manufacturers Select 2025 high quality Soybean Oil Refinery products in best price from certified Chinese Oil Machinery manufacturers, Oil Press suppliers, wholesalers and factory on Made-in-China

Get Price

3. Refinery plant of soybean oil extraction plant: Soybean oil refining process flow chart. a.Degumming and deacidification section: This part is used for removing the phospholipid and FFA in the crude oil. b.Decolorization section: this part is utilizing the white clay to get rid of the pigment in the soybean oil. It can make the soybean oil

Get Price

The plant uses a kind of solvent (normal hexane) to absorb the oil from soybean, and then the machines separate the solvent from soybean crude oil. The solvent is used for recycling and soybean crude oil is refined by oil refinery plant. Features of Soybean Oil Solvent Extracting Technology. High oil yield. Residual oil in soybean meals is <1%.

Get Price

China Crude Soybean Oil Refinery manufacturers Select 2020 high quality Crude Soybean Oil Refinery products in best price from certified Chinese Oil Machine manufacturers, Oil Press suppliers, wholesalers and factory on Made-in-China

Get Price

For manufacturers of large quantities of soybean oil production and processing, it is also very tempting. Besides, good soybean oil press equipment also has longer service life than poor ones. In addition, due to the high oil rate of soybean, it could easily lead to clogged oil line in the pressing process. So you can add small amount of cake

Get Price

This is a 100tpd soybean oil plant in Zambia designed and installed by Machinery. It was begun building in 2010, and finished in 2011. It includes storage silo and oil mill plant, as well as a 10t/h feed pellet plant. The soybean oil mill plant is composed by soybean preatment, soybean oil extration, soybean oil refining and oil packaging.

Get Price

3. Soybean Oil Refining Crude soybean oil is processed through filtering, degumming and deacidifying process, finally get the high-quality soybean oil after deodorization. Before oil refining process, sample examination must be made. Make necessary data detection according to its impurity content, acid value, phosphorus content and pigment

Get Price

We offer 6,130 refinery plant soybean oil products. About 1% of these are soybean oil, 1% are palm oil, and 1% are sunflower oil. A wide variety of refinery plant soybean oil options are available to you, such as soybean oil, sunflower oil, and palm oil.

Get Price

Superfine Fragrant Soybean Oil Refining Process This workshop adopts the production technology of batch refining. According to the type and quality of the crude oil, the process parameters are adjusted and different refining methods are selected to produce the first and third-grade oils.

Get Price

The process of the soybean oil plant typically consists of five steps: oilseed handling/elevator operations, preparation of soybeans for solvent extraction, solvent extraction and oil desolventizing, flake desolventizing, and oil refining. The following pictures shows some of the soybean oil processing plants. Soybean oil is an edible oil with

Get Price

Soybean concentrated phospholipid is a by-product of soybean oil refining hydration oil foot as raw material, using phospholipid product obtained by vacuum continuous film evaporation dehydration, and then decolorized and fluidized to dry. The soybean concentrated phospholipid production process designed by LINGFINE has the following

Get Price

Soybean Oil: Production Process, Benefits and Uses in Pharmaceutical Dosage Form H 4ZADE Edible Oil Refinery & Cold Pressed Oil Plant, Konya, Turkey intechopen. Soybean and Health 284 Soybean dehulling methods differ primarily in the technique used to attain targeted moisture range. There are three types of dehulling methods; In Conventional Dehulling soybean tempering

Get Price

Cleaning of soybeans First the soybeans are cleaned, dried and dehulled . The soybean hulls need to be removed because they absorb oil and give a lower yield. Dehulling is done by cracking the soybeans and a mechanical separation of the hulls and

Get Price

Advantages of Mectech Soya Refining Oil Plant. Today, Mectech is a leading Soybean Oil Extraction Plant manufacturer or Soybean Oil Plant manufacturer in India and abroad with its latest techniques and energy efficient plants. Being one of the leading Soybean Refined Oil Plant suppliers, we have supplied more than 350 plants in different parts

Get Price

Soybean seed processing flow chart shows how the seed is processed to make oil from Seed of the Soybean. Leading manufacturer of Oil Screw Press.

Get Price

Soybean Oil Refining. KMEC's line of soybean oil refining process systems are specially designed to produce an odorless, bland, and stable oil with the appropriate color for a wide variety of cooking and baking applications. From low-cost production of bulk commodity salad and cooking oils to development of the most sophisticated designer-type oils and fats system, KMEC provides the processor

Get Price

Here we will introduce the main parts of the soybean oil extraction plant (solvent extraction process). Soybean oil is the world's largest production edible oil, henan huatai soybean oil extraction machinery has four workshops: soybean pretreatment,soybean oil extraction plant, soybean crude oil refining plant, soybean refined oil filling plant.

Get Price

The process of neutralization, de-acidification, is also called caustic refining and physical or steam refining depending on the process used. Caustic refining means treatment of an oil or fat with an aqueous alkali solution, including water washing. This chapter discusses caustic refining of soybean oils, using both batch and continuous systems, followed by a brief description of physical or

Get Price

The technical teams are ready to help you design and install oil mill plant project based on your oilseed type, yield & budget. Numbers of oil mill plants for manufacturing soybean oil, peanut oil, coconut oil, sesame oil,cottonseed oil, rapeseed oil, sunflower oil, corn germ oil, palm oil and palm kernel oil, etc. have been exported & installed to various countries like India, Nigeria

Get Price