biodiesel and livestock feed from Vermont oilseeds at a farm scale and a commercial scale. Technical feasibility at the farm scale is assessed using data from two Vermont farms. Enterprise budgets are used to assess the economic feasibility and profitability of the crop, oil and meal, and biodiesel enterprises individually and as a whole under two

This study investigates the technical and economic feasibility of producing biodiesel and livestock feed from Vermont oilseeds at a farm scale and a commercial scale. Technical feasibility at the farm scale is assessed using data from two Vermont farms.

Get Price

Technical feasibility at the farm scale is assessed using data from two Vermont farms. Enterprise budgets are used to assess the economic feasibility and profitability of the crop, oil and meal, and biodiesel enterprises individually and as a whole under two sets of market conditions.

Get Price

"Feasibility of on-farm or small scale oilseed processing and biodiesel production," Integration of Agricultural and Energy Systems Conference, February 12-13, 2008, Atlanta, Georgia 48710, Farm Foundation.

Get Price

So when a friend suggested a big leap toward growing oilseed crops and producing biodiesel on the farm, Williamson grabbed hold of the notion. With his creation of State Line Biofuels, Williamson became the first farmer in Vermont to develop an on-farm facility for processing biodiesel from oilseed crops grown on his own farm and those of his

Get Price

The following study is about the feasibility of the installation of a biodiesel plant from oil seeds. As a feasibility study, this dissertation aims to define the requirements for a biodiesel plant and the strategic issues to be considered to assess its feasibility, or likelihood of succeeding.

Get Price

Small-scale biodiesel production economics can vary substantially depending on an individual producer choice of feedstock, equipment, market, and the value of his or her time. However, several key issues affect all small scale producers. Oil. Small-scale biodiesel processors may be able to collect oilseeds or waste oil for very little expense.

Get Price

This study investigates the comparative economic analysis with technical and economic feasibility of producing biodiesel and by-products from soybean and sunflower at a farm scale (i.e annual capacity of less than 1,500 gallons) at three different production stages namely; seed, oil and seed meal, and biodiesel production.

Get Price

million gallons. The technical feasibility of producing biodiesel in small quantities creates the potential for on-farm biodiesel production. Small Scale Production Process Small scale biodiesel production follows the same basic process, regardless of the quantity produced, although differences in inputs, equipment, and the

Get Price

rural areas of Ghana. This paper presents a comparative technical feasibility of jatropha oil as fuel and biodiesel in MFPs. It also presents the findings from a study carried out in Ghana with respect to the promotion of jatropha oil as a fuel in rural areas of Ghana. Keywords: Jatropha, Crude oil, Renewable energy, Biodiesel . 1. Introduction

Get Price

The goal of this paper is to design the process and evaluate the financial feasibility of converting farm crops into biodiesel using a small-scale biodiesel production facility on a farm. Five crops were selected as design alternatives based on regional availability, productivity, and cost criteria: Canola, Corn, Peanut, Soybean, and Sunflower.

Get Price

We are BIG ALWAYS BEAUTIFUL? Option Scale Product Capital cost 190 1A Farm Crude Oil ** 拢7.3k 355 1B Farm Biodiesel 拢30.4k 1,030 2 Small Group Crude oil ** 拢81.2k 15,000 3 Group Biodiesel 拢3.6m 60,000 4 Medium Biodiesel 拢10.2m 250,000+ 5 International Biodiesel 拢25m ** Not eligible for fuel duty rebate

Get Price

ATTRA Webinars. Get expert information about the basics of biodiesel production and learn about how to incorporate the fuel on your farm or ranch; watch Getting Started in Farm-Scale Biodiesel Production. Watch it 禄 (1hr 08min) The second installment of ATTRA's farm-scale biodiesel production webinar series.

Get Price

feasibility study & preliminary business plan for a michigan soybean crush plant, soybean oil refinery and/or biodiesel production plant in gratiot county or other michigan sites phase 2 report feasibility of a stand-alone biodiesel plant (with soybean crush plant & soy oil refinery subject of a prior phase 1 report) prepared by & for

Get Price

Making Biodiesel: Brew Your Own Biofuel A small community farm explores options for growing crops to produce vegetable oil for fuel. Find out more in this introduction to making biodiesel.

Get Price

rural areas of Ghana. This paper presents a comparative technical feasibility of jatropha oil as fuel and biodiesel in MFPs. It also presents the findings from a study carried out in Ghana with respect to the promotion of jatropha oil as a fuel in rural areas of Ghana. Keywords: Jatropha, Crude oil, Renewable energy, Biodiesel . 1. Introduction

Get Price

Feedstock is by far the big issue regarding the feasibility of a commercial biodiesel plant. The biodiesel production byproducts would be glycerin from all feedstocks and oil seed meal from oil seeds. Glycerin could be problematic for biodiesel plants in the Magic Valley even though it is used in many products and processes.

Get Price

Technical and Economic Feasibility of Biodiesel Production in Vermont: Evidence From a Farm-Scale Study and a Commercial-Scale Simulation Analysis. May 2009. Christopher W. Callahan, A Feasibility Analysis of a Mobile Unit for Processing Oilseed Crops and Producing Biodiesel in Vermont. December 2008.

Get Price

5 Transport biofuels: biodiesel and bioethanol. Biodiesel is produced from oil-seed crops, such as oilseed rape, sunflower oil, palm oil and soybean oil. Oilseed rape is the main oil crop in the UK and yields approximately 1300 litres of biodiesel per hectare planted. Making the decision to study can be a big step, which is why you'll

Get Price

Process design and economic risk analysis were performed for a biodiesel production plant having an annual production capacity of 45,000 tonne of biodiesel using inedible Jatropha oil as the

Get Price

2.4.3 Survey of practical issues: technical 20 2.5 Assessment of economic potential 22 2.5.1 Onarm processing options for oilseed rape 22 2.5.2 Standardised costs and returns 22 2.5.3 Sensitivity analysis 30 2.5.4 Markets for biodiesel and coroducts 31

Get Price

The Vermont Bioenergy Initiative provided grant funding and agronomic and financial planning assistance to farmers and entrepreneurs interested in developing homegrown bioenergy and supported the development of on-farm oilseed production, processing, and biodiesel production capacity for farm and local community use, as well as with researchers

Get Price

These oil-rich algae can then be extracted from the system and processed into biodiesel, with the dried remainder further reprocessed to create ethanol. Algal companies specialized in Biodiesel production The following is a list of companies developing processes for the production of biodiesel from algae oil.

Get Price

Capability for large-scale conversion of algal oil into biodiesel The first two aspects are specific to algae, while the third is a generic aspect for biodiesel production from all plant oils. Based on the current research inputs, it appears that the real concern would be condition # 1: Capability to sustainably produce high-oil-yielding algae

Get Price

The technical challenge is to demonstrate the feasibility of the production and use of a renewable bio-based diesel fuel as an alternative to petroleum-based diesel. The innovative objectives of the project are to: Demonstrate the engineering and economic feasibility of biodiesel fuel production from agricultural-based oils and ethanol.

Get Price

Oilseed rape goes from biodiesel to a food oil crop While cold-pressed rapeseed oil was new in New Zealand, it was a big market in Europe and Britain. a group of large-scale Mid and South

Get Price

A feasibility study into biodiesel from micro-algae showed that presently the cost price could be reduced to 鈧?/kg. By making use of residues such as wastewater and CO 2 from exhaust gases, by improving the technology and by shifting production to sunnier countries, it would even be possible to reduce the price of micro-algae biodiesel to one

Get Price

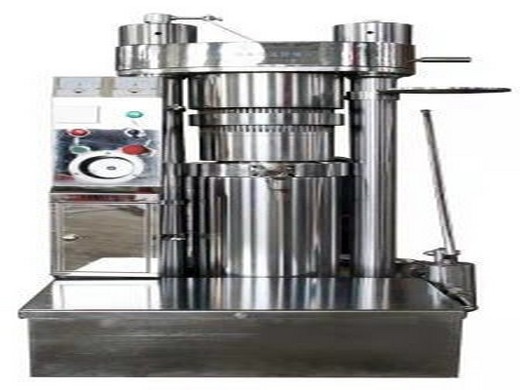

Page 2 Oilseed Processing for Small-Scale Producers the moisture content of the seed should be close to 10%. Th e number varies consider-ably for specifi c oilseeds. For example, rape-seed should be dried to a 7% moisture con-tent, camelina to about 6%, and sunfl ower to 8.5%. Saffl ower needs only to be dried

Get Price

The mini-refinery can accept a large variety of feedstocks for the production of biodiesel including oil from crushed seeds, waste vegetable oil, and straight vegetable oil. For ethanol production, the system can accept such feedstocks as corn germ mash, sugar and even waste alcohol from restaurants and bars.

Get Price

UVM Extension and the UVM Center for Sustainable Agriculture led research on croptrials and farm-scale biodiesel production during the 2006 and 2007 growing season, whileresearchers at the UVM Department of Community Development and Applied Economicscompiled this report and explored the current and potential markets for oilseed co-products.This

Get Price

The nomenclature of biodiesel was adopted considering the precursor oil and alcohol used in transesterification, p.e. soybean methylic (the biodiesel was synthesized from soybean oil and methanol), and B7 is a commercial fuel in Brazil (a mix of 7% of biodiesel and 93% of diesel).

Get Price

Capability for large-scale conversion of algal oil into biodiesel The first two aspects are specific to algae, while the third is a generic aspect for biodiesel production from all plant oils. Based on the current research inputs, it appears that the real concern would be condition # 1: Capability to sustainably produce high-oil-yielding algae

Get Price

A feasibility study into biodiesel from micro-algae showed that presently the cost price could be reduced to 鈧?/kg. By making use of residues such as wastewater and CO 2 from exhaust gases, by improving the technology and by shifting production to sunnier countries, it would even be possible to reduce the price of micro-algae biodiesel to one

Get Price

processing alternatives, i.e. refining food grade oil or producing biodiesel. Objectives The overall objective was to assess the feasibility of a producer-owned winter canola processing facility, with and without further processing into food grade refined oil or biodiesel . Specific objectives were to:

Get Price

The purpose of the Vermont Bioenergy Initiative (VBI) was to foster the development of sustainable, distributed, small-scale biodiesel and grass/mixed fiber industries in Vermont in order to produce bioenergy for local transportation, agricultural, and thermal applications, as a replacement for fossil fuel based energy. The VBI marked the first strategic effort to reduce Vermont dependency

Get Price

This study focuses on the economic feasibility for large-scale biomass production from soybeans or switchgrass from a region in Argentina. This is determined, firstly, by estimating whether the potential supply of biomass, when food and feed demand are met, is sufficient under different scenarios to 2030.

Get Price

Oilseed rape goes from biodiesel to a food oil crop While cold-pressed rapeseed oil was new in New Zealand, it was a big market in Europe and Britain. a group of large-scale Mid and South

Get Price

We run the Bio Pro 190 automated Biodiesel Processor, yet many of the pump heads are having issues after about 40,000 gallons so we are currently running all the processes in manual mode until we

Get Price

A 'read' is counted each time someone views a publication summary (such as the title, abstract, and list of authors), clicks on a figure, or views or downloads the full-text.

Get Price