Vegetable oil refining machine is to refine the crude vegetable oil into high quality edible oil. Vegetable oil refining machine can be devided three types: batch type, semi-continuous type and fully-continuous type.

Edible oil refinery machine manufacturer supplies vegetable oil refinery plant for refining crude palm oil, soybean oil, sunflower oil, etc, with mature oil refining technology and factory price. This 50tpd continuous soybean oil refining machine is designed for continuous operation.

Get Price

Continuous cooking oil refinery. 2025-11-11 16:12; Oil refining process; Chat Online; Get price; Continuous cooking oil refinery workshop. Continuous cooking oil refinery is the newest technology to refine edible oil. Comparing with batch cooking oil refinery and semi-continuous cooking oil refinery, continuous cooking oil refinery has following advantages.

Get Price

Company is a very professional cooking oil refinery machine manufacturer in China, and we can provide 1 ton to 600 tons per per day input capacity cooking oil refinery machine. The popular capacity is mini cooking oil refinery machine from 1-5 tons, small scale cooking oil refinery plant from 5-20 tons.

Get Price

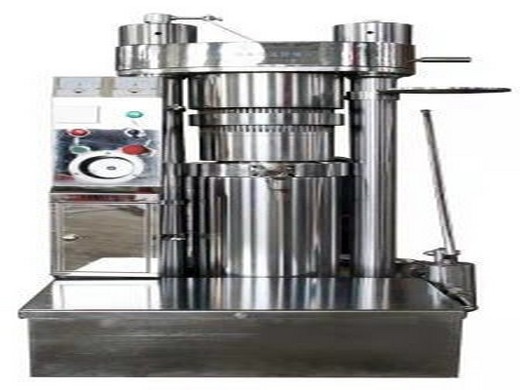

100kg/h Vegetable Edible Cooking Oil Refining Machine Small Oil Production Line , Find Complete Details about 100kg/h Vegetable Edible Cooking Oil Refining Machine Small Oil Production Line,100kg/h Oil Refining,Edible Oil Refining Machine,Small Oil Production Line from Oil Pressers Supplier or Manufacturer-Gongyi Xiaoyi Jinwang Machinery Factory.

Get Price

As a prominent edible oil mill machinery manufacturer who is devoted to processing pure edible oil for worldwide customers, we can provide professional technical support and manufacture first rate oil machines for your edible oil refining. We can provide turnkey oil refining solution with capacities from 1-20T/D. Our cooking oil refining plant

Get Price

1-10TPD small scale edible oil refining plant manufactured by company has won the national patent.Our small scale edible oil refining plant are great choice for small capacity oil mill.The small scale oil refining plant can remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities in the oil.

Get Price

In semi-continuous cooking oil refining process, the cooking oil degumming machine is also degumming pot. In fully-continuous cooking oil refining process, the cooking oil degumming machine is two centrifugal separators. It it no doubt that centrifugal separators substantially increase process efficiency and stability in terms of quality of

Get Price

Degumming Process Palm Oil,Rapessed Oil Refinery,Oil Refining Equipment From Dingsheng , Find Complete Details about Degumming Process Palm Oil,Rapessed Oil Refinery,Oil Refining Equipment From Dingsheng,Oil Refinery,Palm Oil Refinery,Rapessed Oil Refining Equipment from Oil Pressers Supplier or Manufacturer-.

Get Price

This 3D video shows our 1tpd mini edible oil refinery machine working process, including degumming, deacidification, decolorization and deodorization four steps. Besides, it also demonstrates how the heat conductive oil and the cooling water recycles.

Get Price

We offer 4,483 oil degumming products. About 49% of these are Oil Pressers. A wide variety of oil degumming options are available to you,

Get Price

model zx18a (200-3) palm fruit oil refining machine in canada. Palm oil refining line - Palm oil extraction machine. Palm oil refining: 1.Filtration: The purpose of this step is to remove the granular impurities in palm oil. 2.Degumming: Pumping crude oil into oil refining tank, stirring quickly, and simultaneously heating by steam or heat-transfer oil(in coiled heater).

Get Price

Sure, we can also customize the input capacity of mini oil refinery machine according to your requirement. 1-20tpd are all OK. The 3D picture of mini oil refinery machine for refining soya bean oil. The mini oil refinery machine for refining soya bean oil includes degumming, deacidification, decolorization and deodorization four processes.

Get Price

Process Description of Vegetable Oil Refining is as follows. Water Degumming :- Water Degumming is first step in the Edible Oil Refinery Process. Oils contains Hydratable Phosphatide which absorb the water, that Hydratable Phosphatides are oil-

Get Price

This physical refining process is becoming more popular. Chemical Refining In Chemical Refining, Vegetable Oil is treated with caustic lye for separation of free fatty acids from oil. This is a conventional process that can be applied to all oils. A byproduct of alkali refining is soapstock, which is used for manufacture of low quality washing

Get Price

This 3D video shows our 1tpd mini edible oil refinery machine working process, including degumming, deacidification, decolorization and deodorization four steps. Besides, it also demonstrates how the heat conductive oil and the cooling water recycles.

Get Price

Small scale oil refining machine is designed with own heat source, electric control system. User only need to prepare power, water, fuel, caustic soda, phosphoric acid and clay etc to complete the oil refining process. Major process during high grade oil refining process: Neutralization pot: For acid refining, alkali refining and water washing.

Get Price

If your crude palm oil capacity is very small, less than 10tpd, the palm oil chemical refining methods is more suitable. For large capacity above 30tpd, Dry-degumming full contunuous palm oil refinery method is the best choice. Continuous palm oil physical refinery process flow chart: Continuous palm oil refining machine

Get Price

Kinds of edible oil refining machine Henan Huatai Company have three kinds of edible oil refining machine: batch type, semi-continuous type, and full-continuous type. But the most popular edible oil refining machine for customers is batch t. degumming, palm oil refining,crude oil refinery, cooking oil refining plant, any need, please

Get Price

Food grade vegetable seeds cooking oil making machine Machinery Equipment. We provide high quality 30-3000TPD All-continuous oil refining Technology, offer oil mill plant Fully Continuous Edible Oil Refinery,manufacture of High technology palm oil refining line ,Our company is specialized in palm oil refining line. We can provide palm oil refinery machine from 1 ton to 600 tons.

Get Price

October 30, 2017 Cooking Oil Physical Refining Machine. Distillation deacidification method called physical refining conduct steam distillation under high temperature and high vacuum,make the free fatty acids and low molecular substances discharged together with steam,utilize that the relative volatility of edible oil (triglycerides) and free fatty acids is different.

Get Price

Sure, we can also customize the input capacity of mini oil refinery machine according to your requirement. 1-20tpd are all OK. The 3D picture of mini oil refinery machine for refining soya bean oil. The mini oil refinery machine for refining soya bean oil includes degumming, deacidification, decolorization and deodorization four processes.

Get Price

The whole corn germ oil refining plant contains three workshops: corn germ pretreatment workshop, corn germ oil extraction workshop and corn germ oil refining workshop/Line. Craft flow for corn germ oil refining workshop: Crude corn germ oil 鈫?degumming and deacidification鈫?decolorization 鈫抎eodorization 鈫?refined corn germ oil.

Get Price