We are able to supply the professional oil refining plant and related oil refining equipment. With the high degree of automation, the oil refining machinery can refine 20 kinds of oil, such as soybean, rape seeds, peanut, etc. in a small production line or in large oil plant. The Process of Cotton Seeds Oil Refinery Plants

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

Get Price

Cottonseed Oil Refining Plant Main Equipment: degumming tank, heat exchanger, decolorization tower, filter, dedorization tower, etc. Main Specification: 30~1500T/D Cottonseed oil refining equipment applies to cotton seed oil, soybean oil, rapeseed oil, camellia seed oil, corn germ oil, rice bran oil, sunflower seed oil, etc.

Get Price

Edible oil refinery plant and edible oil refining process . Edible oil refining is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils.

Get Price

So called “refinery”, generally refers to deacidificationprocess. But in the broad sense, oil refinery process includes crude oil pretreatment, degumming, deacidifying, decoloring, deodorization, degreasing, and dewaxing process, etc. We will design the refining process depending on the quality requirements of refined oil.

Get Price

Edible Oil Refining Process. The edible oil refining equipment Machinery provide is suitable for refining all kinds of crude vegetable edible oil, such as rice bran oil, peanut oil, soybean oil, sunflower oil, palm oil, palm kernel oil, cottonseed oil, olive oil, mustard oil, coconut oil, etc.

Get Price

Introduction to Cottonseed Oil Extraction Plant Cottonseed oil extraction plant adopts solvent extraction method to extract cottonseed oil.The cottonseed oil plant includes cottonseeds pretreatment and prepressing workshop, cottonseed cake solvent extraction workshop and crude cottonseed oil refinery plant.

Get Price

Oil bleaching process can efficiently process turbid crude oil into transparent and bright oil by removing pigment, residual soap, and odorous substances. The deodorization of oil is applied in most refining industry by using bleaching machine, leaf filter, and vacuum system equipment.

Get Price

Crude Oil Refinery Section. Capacity 10-600T/D. Oilseed soybean oil, rapeseed oil, peanut oil, cottonseed oil, sunflower oil, palm oil. Application intermittent, continuous edible oil refining process for multiple vegetable oil refining. Description Oil Refining workshop main process: Decolorization, dewaxing, deacidification and deodorization. Mixed oil through oil refining plant to get the ...

Get Price

The process of alkaline refining of cottonseed oil is studied and the methods of increasing the yield of neutralized oil are offered. It was revealed that during the refining process of cottonseed oil an increase in the temperature of the process causes a transfer of additional 2,2% oil into waste. It is shown that the neutralized oil yield increases slightly without drying of hydrated oil

Get Price

China Crude Peanut Cottonseed Oil Refinery for Sale, Find details about China Crude Peanut Oil Refinery, Cottonseed Oil Refinery from Crude Peanut Cottonseed Oil Refinery for Sale Henan Best Grain And Oil

Get Price

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed

Get Price

China Crude Oil Refining Plant China Oil Refining Machine. China Crude Oil Refining Plant, Find details about China Oil Refining Machine, Oil Machine from Crude Oil Refining Plant . sunflower seed, soybean, peanut, sesame, corn germ, tea seed, rapeseed, cottonseed, etc: Crude Oil Refinery Plant

Get Price

China Crude Oil Refinery Plant Cottonseed Oil Refining Process Corn Germ Oil Refinery, Find details about China Refinery Equipment Manufacturers, Oil Refinery Plants from Crude Oil Refinery Plant Cottonseed Oil Refining Process Corn Germ Oil Refinery

Get Price

Crude Oil Refinery Section. Capacity 10-600T/D. Oilseed soybean oil, rapeseed oil, peanut oil, cottonseed oil, sunflower oil, palm oil. Application intermittent, continuous edible oil refining process for multiple vegetable oil refining. Description Oil Refining workshop main process: Decolorization, dewaxing, deacidification and deodorization. Mixed oil through oil refining plant

Get Price

Edible oil refinery plant and edible oil refining process . Edible oil refining is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant,

Get Price

1-600 T/D cooking oil refining plant for sale _Factory. After oil pressing process or oil extraction process, we get crude oil. But the crude oil cant flow to supermarket. The crude oil must need processing with cooking oil refining plant, especially soybean, cottonseed

Get Price

Cottonseed oil refinery plant is a necessary part of cottonseed oil mill plant. Because crude cottonseed oil cannot be directly used by human if without any farther refining process. Cottonseed oil

Get Price

Generally, refining of crude vegetable oil defined by two methods: Physical refining and chemical refining. However, it doesn’t matter what kind of refining method to be used, they all are done with the help of various equipments & machinery inside the refinery and all the oils extracted from oil seeds like Sunflower, Cottonseed, Peanuts, Sesame, Soybean etc. Follows these methods of refining.

Get Price

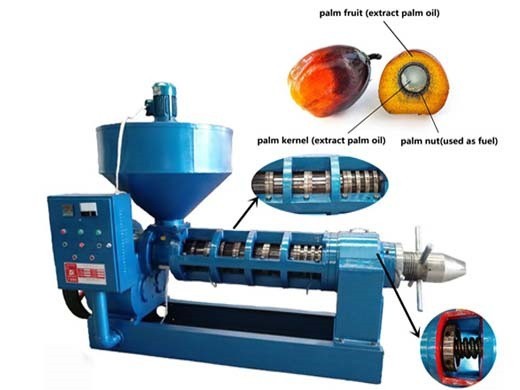

Manufacturing Palm kernel oil refining process/crude oil refining machine,The purpose of palm kernel oil refining process is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality oil

Get Price

Edible Oil Refining Process. The edible oil refining equipment Machinery provide is suitable for refining all kinds of crude vegetable edible oil, such as rice bran oil, peanut oil, soybean oil, sunflower oil, palm oil, palm kernel oil, cottonseed oil, olive oil, mustard oil, coconut oil

Get Price

Oil bleaching process can efficiently process turbid crude oil into transparent and bright oil by removing pigment, residual soap, and odorous substances. The deodorization of oil is applied in most refining

Get Price

China Edible Oil Refinery/Cottonseed Oil Refining Mill Crude Palm Oil Refinery Plant, Find details about China Palm Oil Refinery Machines, Peanut Oil Refinery Machine from Edible Oil Refinery/Cottonseed Oil Refining Mill Crude Palm Oil Refinery Plant

Get Price

Cottonseed Oil Mill Plant [Project Display] A cottonseed oil mill plant that has a commercial grade is likely to be compatible with solvent extraction, which requires cottonseed cake solvent extraction workshop, crude cottonseed oil refinery

Get Price

How Oil Refining Works. by Craig Freudenrich, Ph.D. The Refining Process. As mentioned previously, a barrel of crude oil has a mixture of all sorts of hydrocarbons in it. Oil refining separates everything into useful substances. Chemists use the following steps: airports and chemical plants. In addition to making the oil

Get Price

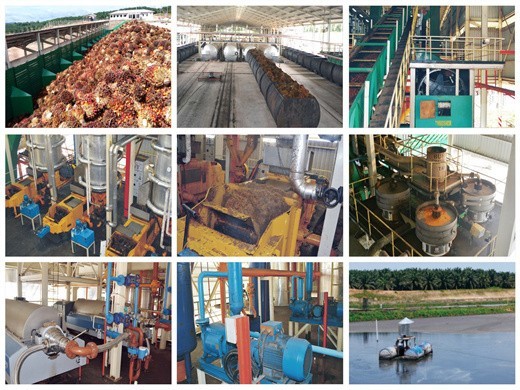

Small scale palm oil refining plant Introduction: Our small scale palm oil refining plant are great choice for small capacity palm oil refinery plant.The small scale palm oil refining plant can remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities in the crude palm oil.Our small scale palm oil refining plant is widely used in cooking oil refining process

Get Price

Small scale oil refining plant Introduction: Our small scale oil refinery plant are great choice for small capacity oil refinery machine.The small scale oil refinery production plant can remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities in the oil.

Get Price

We offer 209 cottonseed crude oil refinery plant products. About 0% of these are Machine Oil Purifier, 99% are Oil Pressers. A wide variety of cottonseed crude oil refinery plant

Get Price

3TPD Crude Peanut Groundnut Oil Refinery for Edible Oil Plant There are certain NonTriglyceride factors exsit in the crude oil, such as free fatty acid, water, suspended impurities, volatile matter, odors and etc. The oil refinery adopts the advanced technology to separate the impurities from oil, and then get edible oil with standard quality .

Get Price

6YL Screw Oil Hot and Cold Press Machine. Palm Fruit Oil Production Line. Soybean Protein Isolate. Oil Solvent Extraction Mill Machine. Vegetable Seed Oil Press Extraction Machines. Oil Refining Machinery. Sunflower Oil Production Line/Peanut Oil Press Machine

Get Price

Crude oil refineries employ some of the United States’ top scientists, engineers, and safety professionals to ensure that products are produced efficiently and safely. US refineries process about 17 million barrels of crude oil a day. Refinery configurations vary, but US refineries are undeniably some of the world’s most sophisticated

Get Price

Goyum India offers turnkey solutions for palm oil refinery plant, including physical refining and chemical refining of palm oil. We manufacture and supply palm oil refinery plant and machinery to process the crude palm oil.

Get Price

Cottonseed oil refinery plant is used for producing the first or second grade edible oil. We are able to supply the professional cottonseed oil refinery plant and related oil refining equipments. With high degree of automation,the cottonseed oil refinery plant can refine 20 kinds of oil, such as soybean, rape seeds, peanut, etc. in a small production line or in large oil plant.

Get Price

Oil Refinery, Oil Press, Oil Extraction manufacturer / supplier in China, offering Crude Palm Oil Refining Machine, Malaysia Palm Oil Refinery, Discount Price Small Animal Floating Fish Feed Pellet Making Extruder Machine, Great Reputations Pet Dog Food Pellet Making Machine and so on.

Get Price

Introduction to Cottonseed Oil Extraction Plant Cottonseed oil extraction plant adopts solvent extraction method to extract cottonseed oil.The cottonseed oil plant includes cottonseeds pretreatment and prepressing workshop, cottonseed cake solvent extraction workshop and crude cottonseed oil refinery plant.

Get Price

Main Oil Refining Process Degumming. In this process, water or acid are added to the oil. After a certain reaction period the gums can be separated either

Get Price

Edible/vegetable oil refining is a step by step process. Refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. The entire oil refining plant process comprises degumming/neutralization, bleaching, deodorization, and winterization.

Get Price