Continuous oil refinery plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This continuous oil refinery plant is bit expensive than batch type oil refinery plant but it provides superior quality refined oil along with automation system and low processing cost.

Continuous Type Oil Refinery Plant Continuous Type Oil Refinery Plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This process line is bit expensive than batch process but it provides superior quality refined oil along with automation system and low ...

Get Price

We offer 293 continuous cooking oil refinery plant products. About 70% of these are oil pressers, 1% are machine oil purifier. A wide variety of continuous cooking oil refinery plant options are available to you, such as automatic, semi-automatic.

Get Price

Continuous cooking oil refinery is the newest technology to refine edible oil. Comparing with batch cooking oil refinery and semi-continuous cooking oil refinery,the whole continuous cooking oil refinery process can be controlled by computer, so the big capacity can be processed per day.

Get Price

Cooking oil making machine manufacturer supplies high quality low cost price cooking oil processing machine, edible oil refinery machine. Offer turn-key service for vegetable oil processing plant projects.

Get Price

In batch oil refinery process or cooking oil refinery process, a measured quantity of oils is processed in sequence of neutralizing, bleaching & deodorizing. Crude oil obtained from expellers or solvent extraction plant contains foreign impurities such as mucilage, gums, coloured & unfiltered proteinous matter from the seed. Also Free Fatty ...

Get Price

Edible continuous oil refinery plant is recommended for higher capacity plants above 30 tons per day and for oils containing higher FFA content for cooking oil refinery plant. This process line is better than batch process and it provides superior quality refined oil along with automation system and low processing cost.

Get Price

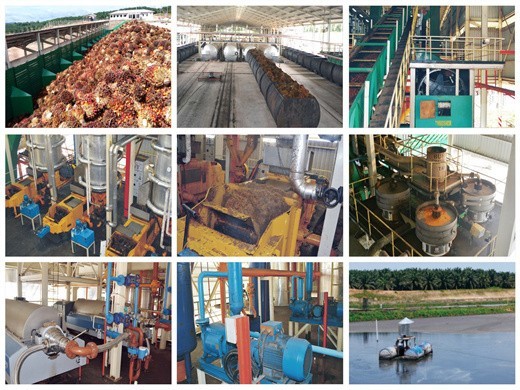

Our cooking oil refinery plant refines crude vegetable oils extracted from soya, palm, sunflower, canola seeds, etc. to covert them to edible oils. Process tons of vegetable crude oil in shorter times.

Get Price

Cooking oil refinery, Edible oil refinery, Vegetable oil refinery, Refined cooking oil production, Vegetable oil processing, Edible oil processing, Palm oil refining, Edible oil refinery plant ...

Get Price

We present one of the most developed Cooking Oil Refinery Plant for processing of edible oil. There are primarily involved two types of processing- batch type and continuous. Through these processes, the oil

Get Price

Continuous Type Oil Refinery Plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This process line is bit expensive than batch process but it provides superior quality refined oil

Get Price

Continuous cooking oil refinery is the newest technology to refine edible oil. Comparing with batch cooking oil refinery and semi-continuous cooking oil refinery,the whole continuous cooking oil refinery

Get Price

Continuous oil refinery plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This continuous oil refinery plant is bit expensive than batch type oil refinery plant but it provides superior quality refined oil

Get Price

Edible continuous oil refinery plant is recommended for higher capacity plants above 30 tons per day and for oils containing higher FFA content for cooking oil refinery plant. This process line is better than batch process and it provides superior quality refined oil

Get Price

In batch oil refinery process or cooking oil refinery process, a measured quantity of oils is processed in sequence of neutralizing, bleaching & deodorizing. Crude oil obtained from expellers or solvent extraction plant

Get Price

Our cooking oil refinery plant refines crude vegetable oils extracted from soya, palm, sunflower, canola seeds, etc. to covert them to edible oils. Process tons of vegetable crude oil in shorter times.

Get Price

What is Oil Refinery and Refined Cooking Oil ? We know that the cooking oil is the primary requirement of the people and hence the production of cooking oils and fats is among the world’s oldest industries. Before one century the same oils were obtained

Get Price

20-50tpd edible oil refinery production machine for sale with factory price_Semi Continuous Edible Oil Refinery plant supplier. After refining, the flavor, color and smell of edible oil is improved, the stability is improved which is good for long time storage, the smoke point of oil is increased.

Get Price

We offer 1,703 continuous refinery oil plant products. About 45% of these are machine oil purifier, 44% are oil pressers. A wide variety of continuous refinery oil plant options are available to you, such as automatic, semi-automatic.

Get Price

semi-continuous oil refinery 10-50TPD Build Oil Mill Plant with BEST Oil Expeller & Refinery Line. The semi-continuous oil refinery process design is based on batch type but higher than batch type. Compared with batch oil refinery line, semi-continuous oil refinery process is more efficient. We receive enquiries in English, Español (Spanish),

Get Price

We are manufacturers and exporters of Continuous Oil Refinery Plants for the efficient and excellent refining of the edible cooking oils. The refined edible oil from our plant shall have a longer shelf life and maximum cutting of FFA.

Get Price

An oil refinery or petroleum refinery is an industrial process plant where crude oil is transformed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene, liquefied petroleum gas, jet fuel and fuel oils. Petrochemicals feed stock like ethylene and propylene can also be produced directly by cracking crude oil without the need

Get Price

The video show that 1-10tpd edible oil refinery process.1-10tpd edible oil refinery plant is widely used to refine almost all kinds of oil extracted from oil seeds like sunflower seeds, linseeds

Get Price

The popular capacity is mini cooking oil refinery machine from 1-5 tons, small scale cooking oil refinery plant from 5-20 tons. They are usually batch type cooking oil refinery machine. Full-cotinuous cooking oil refining machine more than 100tpd is

Get Price

Cooking Oil Refinery Plant 100% Export Oriented Unit of a wide range of products which include batch oil refinery plant, continuous edible oil refinery plant, sunflower oil refinery plant, vegetable oil refining plant, continuous edible oil refinery and cooking oil refinery plant.

Get Price

Cooking Oil Refinery Plant 100% Export Oriented Unit of a wide range of products which include batch oil refinery plant, continuous edible oil refinery plant, sunflower oil refinery plant, vegetable oil refining plant, continuous edible oil refinery and cooking oil refinery plant.

Get Price

The popular capacity is mini cooking oil refinery machine from 1-5 tons, small scale cooking oil refinery plant from 5-20 tons. They are usually batch type cooking oil refinery machine. Full-cotinuous cooking oil refining machine more than 100tpd is

Get Price

Complete Cooking Oil Refinery Process. The process of oil refining in cooking oil refinery plant can be carried out in two different types: continuous refining process and the batch refining process. This mini oil refinery machine belongs to batch refinery. Although the two process have more similarities than differences, the one aspect that sets them widely apart is the production output.

Get Price

China Oil Refinery Plant manufacturers Select 2020 high quality Oil Refinery Plant products in best price from certified Chinese Oil Pump manufacturers, Oil Treatment suppliers, wholesalers and factory on Made-in-China

Get Price

Semi-continuous oil refinery line can get the best quality oil with the less running cost. However, different oils have different refinery processes. Our engineer can help you choose most suitable refinery line according to your capacity and requirements. If you want to know more about oil refinery plant, please feel free to contact us.

Get Price

The batch type process is generally preferred because it has low cost, low effluent generation, easy maintenance and easy to operate making it economically more viable. Numerous TINYTECH batch refinery plants are operational at various places refining different cooking oils. Continuous Type Cooking Oil

Get Price

small sized palm oil refinery plant for sale at factory price If you are planning to set up a small to medium sized palm oil extraction plant, screw type palm oil pressing machine should be the best choice for your oil mill plant. View this article for detailed process feature of screw oil press. Start an Automatic Groundnut Oil Processing Line

Get Price

Provides oil refinery plant,solvent extraction and more informations about oil refinery plant cost and types of cooking Oil . Skip to content. Home; Category Archives: Types of Cooking Oil. Types of Cooking Oil. Posted on August 2, 2012 by admin. There are different types of cooking oil.

Get Price

manufacture of Continuous cooking oil refinery,Continuous cooking oil refinery is the newest technology to refine edible oil. Comparing with batch cooking oil refinery and semi-continuous cooking oil refinery,the whole continuous cooking oil refinery process can be controlled by computer, so the big capacity can be. Send Inquiry

Get Price