Small pyrolysis plant is used to recycle waste tyre and plastic into fuel oil, carbon black and combustible gas. The most unique features of small plant are low investment cost , small occupied area and high profits.It is the best choice for investors who start their pyrolysis business first time.

Continuous Tyre Pyrolysis Plant | Fully Automatic Reactor. Our continuous pyrolysis machine can process 20 to 24 tons of raw materials a day. It is more effective. So if you have a large number of old tires to dispose of, a continuous tyre pyrolysis plant will be the most cost-effective solution for you.

Get Price

When starting a tyre pyrolysis plant business to make money, you must have to consider the various costs of tyre pyrolysis plant.Generally speaking, the waste tyre pyrolysis plant cost is mainly determined by several factors, such as the pyrolysis process, output, overall technology, pyrolysis reactor, condensers and so on.

Get Price

All-around Services to Make Your Cost Worthy. To get a low tyre pyrolysis plant price, someone may choose second-hand pyrolysis plants or that manufactured by the small-scale factories. They pay much attention to the initial pyrolysis plant cost and ignore the importance of follow-up services.

Get Price

a> 100% Waste tyre to oil recycling plant is achieved. b> No chemical ingredients are used in process (environment friendly) c> During and after the process; no soil, water or air pollution is observed.

Get Price

Waste Pyrolysis Plant for Sale | Fair Cost | 20+ Sucessful . Beston waste pyrolysis plant is a kind of environmental project with the principle of turning waste into treasure. The machine mainly utilizes the high temperature anaerobic heating technology to make the molecule regroup, and then produces fuel oil and carbon black.

Get Price

Pyrolysis plant is an industry that converts waste plastic & tires & rubber and other waste materials into Pyrolysis Oil, Carbon Black & Hydrocarbon Gas. The waste plastic and tyre pyrolysis machine can reduce the volumes of the waste products and help human protect the environment.

Get Price

APChemi engineers have been trained for compliance with 'European CE, ATEX standards' as well as the ASME design code. Since over a decade, APChemi as a company is known for being very transparent, robust and cost-effective partners in sustainable pyrolysis of waste plastics, tyre and biomass.

Get Price

Small pyrolysis machine can process 5-10 tons of tyres, rubber and oil sludge. If you want a small scale pyrolysis unit, contact Beston now!

Get Price

Before investing in a waste plastic to oil plant, we need to take the plastic to oil machine cost into account.In most The total cost of plastic to oil machine may be affected by these factors, such as equipment prices, shipping and installation costs, operating and maintenance costs, raw materials and site costs

Get Price

When starting a tyre pyrolysis plant business to make money, you must have to consider the various costs of tyre pyrolysis plant.Generally speaking, the waste tyre pyrolysis plant cost is mainly determined by several factors, such as the pyrolysis process, output, overall technology, pyrolysis reactor, condensers and so on.

Get Price

Before you invest in the tyre to oil business, you may need to know the tyre to oil plant cost.To do a cost estimate will be helpful for your investment. Beston doesn only manufacture quality plants, but also makes sure our customers get as much as profit at the minimum expenditure.

Get Price

01.02.2016· The fully continuous waste tyre to oil machine not only can handle 30-50 tons of waste tires in one day, but also can work continuously for 24 hours. So, it is proved to be high efficiency and

Get Price

The pyrolysis oil can then be used to generate electricity. Our mission is to offer solutions to clean up the environment and thereby also increase the living quality of people on this planet with the added benefit of job creation though our decentralised, green solutions which can be designed to uplift poverty stricken communities.

Get Price

Waste pyrolysis plant can turn waste into fuel oil and carbon black, which will bring investors great benefits.It is widely used to process waste tyres, plastic, oil sludge, rubber, etc.That to say, pyrolysis technology is also beneficial to solving the environmental problem.

Get Price

Oil distillation plant can convert waste oil into pure diesel oil and gasoline. Waste oil involves pyrolysis plastic/tyre oil produced from pyrolysis plant, crude oil, used engine oil, motor oil, as well as lube oil, etc. These diesel oil and gasoline can be used for vehicle.

Get Price

Beston waste tyre pyrolysis oil plant employs the most advanced green pyrolysis technology to maximize the scrap tires into value, such as fuel oil. The pyrolysis oil from tires is a synthetic fuel under investigation as a substitute for petroleum. Besides, you can also get carbon black and steel wire through our waste tire to oil plant.

Get Price

Waste tire oil pyrolysis plant is a technique that waste tires or rubbers or plastics are heated in a sealed reactor vessel and to be pyrolyzed into oil gas, uncondensable gas

Get Price

Waste tyre pyrolysis plant. By using the waste tyre pyrolysis plant,we can get pyrolysis oil from waste tire. Secondly,with the help of one set of tire oil to diesel refining machine, the pyrolysis oil can be further refined into diesel oil or gasoline. Tire oil to diesel refining machine

Get Price

Continuous Tyre Pyrolysis Plant Fully Automatic Reactor. Our continuous pyrolysis machine can process 20 to 24 tons of raw materials a day. It is more effective. So if you have a large number of old tires to dispose of, a continuous tyre pyrolysis plant will be the most cost-effective solution for you. Of course, it is more expensive than the

Get Price

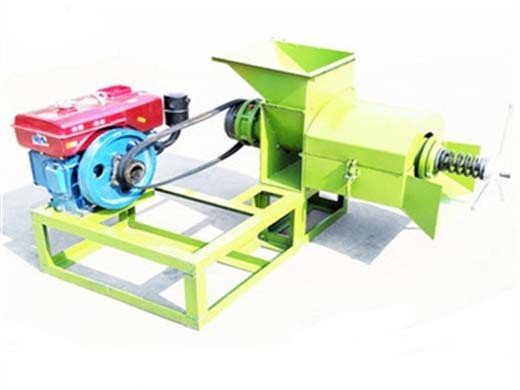

Application of small pyrolysis machine is the most efficient and economic way to recycle tyre, rubber and oil sludge.With small investment and area, this plant changes these wastes into useful resource oil. Compared with continuous type, the small one with rotary reactor need less budget.

Get Price

a> 100% Waste tyre to oil recycling plant is achieved. b> No chemical ingredients are used in process (environment friendly) c> During and after the process; no soil, water or air pollution is observed.

Get Price

China Manufacturer of Waste Tyre Pyrolysis Plant, Pyrolysis . Waste Tyre Pyrolysis Plant. Pyrolysis Plant is used for recycling waste tire, waste plastic, waste rubber to fuel oil. According to the actual situation in every country and district, we developed different models of Batch Pyrolysis Plants for waste tires, rubber and plastic with

Get Price

Tire recycling plant. First, The Waste Tyre Pyrolysis Machine. If you want to use the pyrolysis technology to handle the waste tyres, our tire pyrolysis plant for sale can convert waste tires into fuel oil,carbon black and steel wire under the high temperature in the pyrolysis reactor.

Get Price

Beston pyrolysis plants can turn waste plastic, tyre, rubber, oil sludge, medical waste into fuel oil and other byproducts. If you want to invest in this equipment, please contact us promptly. We will provide you with different types of pyrolysis machine.

Get Price

Why You Should Consider Getting A Tire To Oil Plant Have you ever seriously considered getting a tire to oil plant? In case you have never heard about one, or ever considered purchasing one, this is certainly something that you must do. When you h...

Get Price

06.03.2025· Congratulations! Beston BLJ-16 waste tire pyrolysis plant was shipped to South Africa successfully. Here are the delivery pictures: BLJ-16 tire pyrolysis plant is used to dispose of waste tire. You can get fuel oil, carbon black and steel wire from pyrolyzing. Through knowing the profits of pyrolyzing waste tire project, South Africa customer

Get Price

As you can see, the pyrolysis project is suitable for many different raw materials, such as old tyres, rubber products, oil sludge, plastic, etc. If you want to get your own pyrolysis plant project report, please inform us of some basic information, for example, what and how many raw materials you will process.

Get Price

Bankers Bay is one of such platform where such deals are brokered or investment can be found. There are many such other portals if that is the way you want to take. Still, the best way I see to do it is to look for companies which are dealing upst...

Get Price

Processing Waste Used Tire Plastic Rubber Convert To Diesel Oil Pyrolysis Plant,Find Complete Details about Processing Waste Used Tire Plastic Rubber Convert To Diesel Oil Pyrolysis Plant,Tyre Pyrolysis Plant,Waste Plastic Pyrolysis Oil Plant,Rubber Processing from Machine Oil Filter Supplier or Manufacturer-Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd.

Get Price

22651 products Good Price Waste Tyre Plastic To Fuel Oil Pyrolysis Plant. Add to Compare Mini batch plastic to diesel fuel machine and plastic pyrolysis plant factory Direct newest design waste tire to crude oil pyrolysis plant with CE and ISO Huayin 20 ton waste plastic recycling to oil tyre pyrolysis plant.

Get Price

Beston Machinery is professional one of pyrolysis plant manufacturers in China. We can supply you high quality and non-pollution pyrolysis plants for you. If you have pyrolysis plant business plan, get the pyrolysis plant cost estimate from us. We will customize the pyrolysis plant project report according to your needs.

Get Price

Waste Pyrolysis Plant for Sale Fair Cost 20+ Sucessful . Beston waste pyrolysis plant is a kind of environmental project with the principle of turning waste into treasure. The machine mainly utilizes the high temperature anaerobic heating technology to make the molecule regroup, and then produces fuel oil and carbon black. Both of the end

Get Price

Industrialists that would like to create a fortune need to look towards making an investment in waste tyre pyrolysis plants.This special form of plant is seen as the most efficient pyrolysis plants available on the market at the moment.

Get Price

Waste tyre recycling pyrolysis refers to the process of turning waste tyre into fuels, monomers, or other valuable materials by thermal and catalytic cracking with green and mature technology. With the continuous development of industrial civilization, more and more tyre are widely used in our life, that is why we need to come up with the latest pyrolysis solution to deal with the issue.

Get Price

We establish robust and cost effective Pyrolysis plants on turnkey basis. Pyrocrat has proven technology to convert waste plastic into industrial diesel grade fuel oil called yrolysis oil Over 18 plastic to oil projects established by Pyrocrat convert about 100MT of waste plastic daily into pyrolysis oil.

Get Price