Currently, the sunflower oil sold on the market is mostly produced by de-shelled pre-squeezing and leaching process. De-shelled pressing-leaching technology is the key point of sunflower oil production line which avoids the negative impact of over-refining, high temperature, and acid and alkali effects on oils, so that the nutrients in the oil can be well preserved.

Castor oil is naturally astringent, which helps to pull the impurities from the skin, thus making the pores appear smaller. The sunflower seed oil has a comedogenic rating of zero, to prevent clogging of the pores and to keep the sebum levels balanced. For Oily Skin: A blend of 30% castor oil to 70% sunflower seed oil.

Get Price

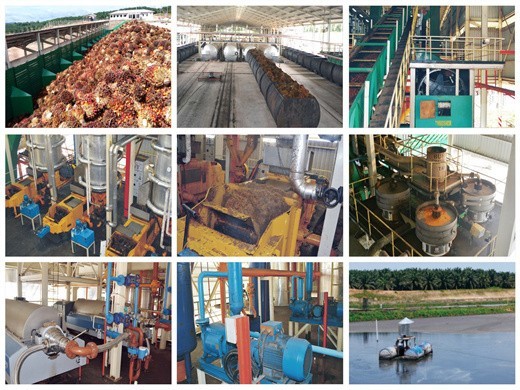

Cost of Setting Up a Complete Castor Oil Plant. There are various processes that are carried out in a castor oil manufacturing plant. To ensure the lowest production cost and highest production production, each project of our castor oil processing plant was designed and built according the specific situation and requirements of our clients.

Get Price

Sunflower seed processing flow chart shows how the seed is processed to make oil from Seeds of the Sunflower. Flowchart for Sunflower Oil Production

Get Price

Purification Section Of Castor Oil Production. Once the oil has been extracted from the seed, it is necessary to remove impurities from the oil.The oil is essentially a pure triglyceride, and contains almost 90% of glyceryl tricinoleate. It is the ricinoleic triglyceride that is needed in order to produce high quality castor oil.The steps to ...

Get Price

For economic reasons it is increasingly popular to start a sunflower oil plant for sunflower oil processing to make cheap sunflower seeds into more valuable and healthy sunflower oils. The sunflower is a distinctive, flowering plant (Helianthus annuus L.), the seeds of which contain a valuable edible oil that contains more Vitamin E than any other vegetable oil.

Get Price

This section of CastorOil.in provides details and web resources on castor oil extraction. Castor Oil Production. Castor seed is grown commercially on plantations but also harvested from wild plants. The seed must be hulled after harvesting. This can be done laboriously by hand or, more commonly, by machine.

Get Price

Castor oil, produced from castor beans, has long been considered to be of important commercial value primarily for the manufacturing of soaps, lubricants, and coatings, among others. Global castor oil production is concentrated primarily in a small geographic region of Gujarat in Western India. This ...

Get Price

Castor oil is often considered a remedy for relieving constipation; however, it can do so much more than that. From helping you regrow and strengthen your hair, to treating arthritis, castor oil uses and benefits are numerous. Since its first uses in ancient Egypt, the various castor oil uses and benefits are popular with people around the world.

Get Price

09.07.2014· Development of oil refining unit. An experimental oil refining unit has been developed for minimal refining of sunflower oil. The unit consists of (i) one open mild steel tank with conical bottom for degumming/neutralization, (ii) one closed oval tank for vacuum drying/bleaching and (iii) one filter for filtration of oil.

Get Price

07.09.2016· Castor oil, produced from castor beans, has long been considered to be of important commercial value primarily for the manufacturing of soaps, lubricants, and coatings, among others. Global castor oil production is concentrated primarily in

Get Price

Castor oil is often considered a remedy for relieving constipation; however, it can do so much more than that. From helping you regrow and strengthen your hair, to treating arthritis, castor oil uses and benefits are numerous. Since its first uses in ancient Egypt, the various castor oil uses and benefits are popular with people around the world.

Get Price

Sunflower oil is the non-volatile oil pressed from the seeds of sunflower (Helianthus annuus).Sunflower oil is commonly used in food as a frying oil, and in cosmetic formulations as an emollient.The world's total production of sunflower oil in 2014 was nearly 16 million tonnes, with Ukraine and Russia as the largest producers.. Sunflower oil is primarily composed of linoleic acid, a

Get Price

contains less than 1% residuaI oil, while it is much fatter when resulting from pressing. The meals are used in animal feed to balance the prote茂n content. To this purpose, they are generally pelletised and named sunpellets. c) Refining Sunflower seed oil obtained by solvent extraction is easy to refine; the basic refining

Get Price

EFISC Guide Sector reference document on the manufacturing of safe feed materials from oilseed crushing and vegetable oil refining 81 Feed Risk assessment of the chain of sunflower seed meal and oil products 2. Drying of sunflower seeds at primary production* HAZARD CAT.

Get Price

This section of CastorOil.in provides details and web resources on castor oil extraction. Castor Oil Production. Castor seed is grown commercially on plantations but also harvested from wild plants. The seed must be hulled after harvesting. This can be done laboriously by

Get Price

OILSEEDS AND OILSEED PRODUCTS Market situation Global soybean production increased strongly in 2016, with the United States and Brazil registering record crops.The aggregate world production of other oilseeds (rapeseed, sunflower seed and groundnuts) increased for the first time in

Get Price

28.07.2017· Provide oil leaching equipment, solvent extraction technology and so on a series of fuel oil production equipment and technology. As a professional oil press manufacturer, our products have been

Get Price

Refining is essential to remove impurities such as colloidal matter, free fatty acid, colouring matter and other undesirable constituents that make oil less resistance to deterioration during storage [2, 3]. Refining of castor oil includes degumming, neutralization, de-waxing, deodorization and bleaching. Castor oil has one double bond

Get Price

Sunflower Oil Refining Plant by Mectech is custom designed employing leading edge state of the art technologies for effective, efficient and optimized functioning in order to generate maximal returns. The major advantages of Mectech Sunflower Oil Refining Plant are :

Get Price

A distillation system is used to recover the solvent from the sunflower oil. The desolventized flakes are then a product and ready for sale as a good source of protein. The sunflower oil can be further refined from a crude product to an edible product. Oil Refining and Processing

Get Price

The manufacturer of sunflower oil in Ukraine offers quality production and collaboration. Our factory is the largest wholesale producer of sunflower oil to the export from Ukraine. We made high quality products at the best prices! KAISSA is a trusted supplier to buy certified Ukrainian oil.

Get Price

The . Sunflower. Production Guide. XXX A SUNFLOWER INDUSTRY PROFILE. The National Sunflower Association of Canada (NSAC), Inc. was initiated at a meeting in Carman, MB on November 18, 1996. The meeting was organized to address the closure of the sunflower oil

Get Price

Castor oil is a popular natural treatment for various common conditions and often used in natural beauty products. This article lists 7 benefits and uses of castor oil.

Get Price

Castor Oil Refin, Castor Oil Refin Suppliers Directory Find variety Castor Oil Refin Suppliers, Manufacturers, Companies from around the World at castor oil ,oil refining machine ,edible oil refining machine, Castor Oil

Get Price

Castor Oil: Properties, Uses, and Optimization of Processing Parameters in Commercial Production. Castor oil, produced from castor beans, has long been considered to be of important commercial value primarily for the manufacturing of soaps, lubricants, and coatings, among others. Global castor oil production is concentrated primarily in a small

Get Price

Characterization of Castor Seed Oil and Its Utilization Potential in the Production of Polyurethane Foam. Walailak Journal of Science and Technology (WJST),11(5): 421-427.

Get Price

Deodorization Section of Sunflower Oil Refining Process. The Deodorization or deacidification is actually stripping process in which a little amount of low pressure steam passes through hot oil. In Sunflower Oil Deodorization process various types of volatile molecule and odoriferous compound removed. This process carried out at very high

Get Price

Blends among fractions, the modification of physical properties of these fractions through interesterification and blends between fractions of Refined Sunflower Oil,Corn Oil,Soybean Oil,RBD Palm Oil,Canola Oil,Olive Oil and Palm Kernel Oil generate a dazzling array of oils and fats each with distinctive oil and fat profiles.

Get Price

The sunflower oil industry in Ukraine continues its rapid development, improving cultivation technology, production and refining. Birthplace of the best sunflower oil . We take great pride in our homeland which is the birthplace of the very best sunflower oil. Ukrainian sun-drenched black soil grows vast fields of these magnificent sun-like plants, which constitute 40% of world exports. We

Get Price

standard specification of castor oil. The refined castor oil then modified for further uses. The different castor seed from different area which is Casa 5 and Casa 101 is extracted to obtain the castor oil and identify which location in Malaysia that the castor seed produces more oil content and have the same standard with world castor oil quality.

Get Price

Sunflower seed oil production does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. 6 Processes of Sunflower Oil Production

Get Price

Castor Oil and Derivatives Market Share Insights. Castor oil and derivatives has an established global market with major applications in the plastics and resins industry. It is obtained by the mechanical crushing of castor seeds, which is further processed to manufacturer bioplastics, diesel, lubricants, drugs, and various other products. In

Get Price

Professional Edible oil pressing machinery manufacturer, provides seed oil extraction, refining equipments,cooking oil expeller, biodiesel machines with reliable service and quality all over the world

Get Price

1. Introduction. Two processes have been developed for the refining of edible oils and fats, i.e. physical and chemical refining; the decision which process to use depends on the types and qualities of the crude oil to be processed (Fig. 1).The names physical and chemical refining come from the process technology used to remove the free fatty acids (FFA) that are responsible for the oil acidity.

Get Price

However, castor oil and its derivatives are used in the production of paints, varnishes, lacquers, and other protective coatings, lubricants and grease, hydraulic fluids, soaps, printing inks, linoleum, oil cloth and as a raw material in the manufacturing of various chemicals sebacic acid and undecylenic acid, used in the production of plasticizer and Nylon [4].

Get Price

According to the global castor oil market report by IMARC Group, the market is projected to reach a volume of 960.5 Kilotons by 2025, growing at a CAGR of 3.3% during 2020-2025.

Get Price

Castor Oil Report Nov 2010 Free ebook download as PDF File (.pdf), Text File (.txt) or read book online for free.

Get Price