Direct energy utilization in nine palmernel oil (PKO) mills located in Southwestern Nigeria was analyzed. The mills were stratified into small, medium and largecale categories, based on their modes of operations and production capacities. Evaluation of energy usage was carried out in the seven readily defined unit operations namely: palmut drying, palmut cracking, palmernel ...

Energy requirements for palmernel oil processing operations Energy requirements for palmernel oil processing operations S.O. Jekayinfa; A.I. Bamgboye 2004-08-01 00:00:00 Direct energy utilization in nine palmernel oil (PKO) mills located in Southwestern Nigeria was analyzed. The mills were stratified into small, medium and largecale categories, based on their modes of ...

Get Price

These industries make use of palm-kernel oil as the basic raw material. As a result, demands for palm-kernel oil have been on the increase without any appreciable profit margin to the producers due to high input energy. Hence, the dwindling production of palm-kernel oil in recent time.

Get Price

Development of equations for estimating energy requirements in palm-kernel oil processing operations

Get Price

A study was conducted to determine the energy consumption in palm-kernel oil (PKO) processing operations as carried out in nine PKO mills in Nigeria. The mills were equally stratified into three categories to represent different mechanization levels and production capacities.

Get Price

Development of equations for estimating energy requirements in palm-kernel oil processing operations Article in Journal of Food Engineering 79(1):322-329 路 March 2007 with 432 Reads

Get Price

The types and magnitudes of the parameters required for the energy evaluation of each unit operation are presented in Table 2. Ezeike (1981) and Jekayinfa and Bamgboye (2003, 2005) have used similar procedure in the energy audits of rice processing mills, palm-kernel oil mills and cashew-nut mills in Nigeria.

Get Price

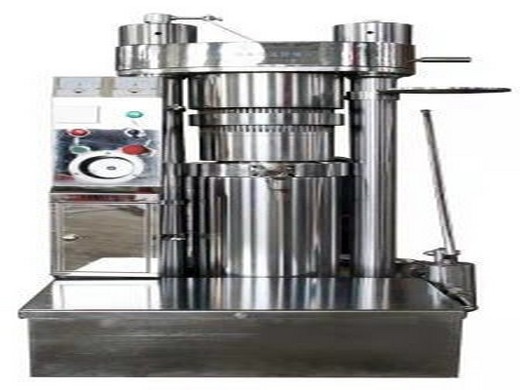

Detail and total price of all equipments for establishing palm kernel processing plant; Hello, dear. It is better to provide us more details about your expected palm kernel oil processing plant, including capacity, final products purpose, requirements, etc.

Get Price

The mill is equipped with a palm kernel crushing plant to produce organic, certified crude palm kernel oil. Packaging plant. Crude palm oil and crude palm kernel oil are packaged on-site into 20-metric tonne flex tanks for export and in 200-litre drums or 20-litre containers for local requirements. Family farm operations. Goldtree supports ...

Get Price