Biodiesel is produced mainly from vegetable oils by transesterification of triacylglycerols. From economic and social reasons, edible oils should be replaced by lower-cost and reliable feedstocks for biodiesel production such as non-edible plant oils.

Biodiesel production from non-edible plant oils ... oils for biodiesel production may lead to food crisis. These problems can be solved by using low-cost feedstocks such as non-edible oils and ...

Get Price

These plants are easily available in developing countries and are very economical comparable to edible plant oils. Biodiesel produced from non-edible plant oils has good potential as an alternative diesel fuel. However, as a serious drawback, most non-edible oils contain a high content of FFAs, which increases the biodiesel production cost.

Get Price

Besides its lower cost, another undeniable advantage of non-edible oils for biodiesel production lies in the fact that no foodstuffs are spent to produce fuel [4]. These and other reasons have led to medium- and large-scale biodiesel production trials in several countries, using non-edible oils such as castor oil, tung, cotton, jojoba and jatropha.

Get Price

cost feedstocks such as non-edible oils and waste cooking oils for biodiesel production. This paper reviews numerous options of non-edible oils as the substantial feedstocks, biodiesel pro-cessing, and effect of different parameters on production of biodiesel. Keywords Non-edible oil, viscocity, FFA, biodiesel, transesterification, fuel ...

Get Price

On the contrary, non-edible vegetable oils have several advantages arising from their use as feed stock for biolubricant production. Non-edible oils are ineligible for human and animal consumption ...

Get Price

Moreover, these oils could be more expensive to use as fuel. Hence, the contribution of non-edible oils such as jatropha and soapnut will be significant as a non-edible plant oil source for biodiesel production. Jatropha is grown in marginal and waste lands with no possibility of land use competing with food production.

Get Price

From economic and social reasons, edible oils should be replaced by lower-cost and reliable feedstocks for biodiesel production such as non-edible plant oils. This paper reviews various methods for biodiesel production from common non-edible oils employing alcoholysis reactions.

Get Price

Production of Biodiesel from Non Edible Oil and its Properties 1546 Biodiesel is an alternative fuel made from renewable biological sources such as vegetable oils both (edible and non edible oil) and animal fats (Antony Raja et al ., 2011). It can be defined

Get Price

Therefore, non-edible plant oils become very promising alternative feedstocks for biodiesel production because of large demand for edible oils as food, the higher prices of edible oils than that of fossil fuels and the lower cost of non-edible oil plant cultivation. However, there will always be a competition between edible and non-edible oily

Get Price

These problems can be solved by using low-cost feedstocks such as non-edible oils and waste cooking oils for biodiesel production. This paper reviews numerous options of non-edible oils as the

Get Price

2016-02-15· These plants are easily available in developing countries and are very economical comparable to edible plant oils. Biodiesel produced from non-edible plant oils has good potential as an alternative diesel fuel. However, as a serious drawback, most non-edible oils contain a high content of FFAs, which increases the biodiesel production cost.

Get Price

Biodiesel is produced mainly from vegetable oils by transesterification of triacylglycerols. From economic and social reasons, edible oils should be replaced by lower-cost and reliable feedstocks for biodiesel production such as non-edible plant oils. This paper reviews various methods for biodiesel production from common non-edible oils

Get Price

2008-02-08· Moreover, these oils could be more expensive to use as fuel. Hence, the contribution of non-edible oils such as jatropha and soapnut will be significant as a non-edible plant oil source for biodiesel production. Jatropha is grown in marginal and waste lands with no possibility of land use competing with food production.

Get Price

cost feedstocks such as non-edible oils and waste cooking oils for biodiesel production. This paper reviews numerous options of non-edible oils as the substantial feedstocks, biodiesel pro-cessing, and effect of different parameters on production of biodiesel. Keywords Non-edible oil, viscocity, FFA, biodiesel, transesterification, fuel

Get Price

Downloadable (with restrictions)! Because of biodegradability and nontoxicity biodiesel has become more attractive as alternative fuel. Biodiesel is produced mainly from vegetable oils by transesterification of triacylglycerols. From economic and social reasons, edible oils should be replaced by lower-cost and reliable feedstocks for biodiesel production such as non-edible plant oils.

Get Price

2017-12-26· ExxonMobil is investing in the production of biodiesel production from non-edible plant oils. Unlike traditional plant sources, the company is going into a new fermentation technology which uses non-traditional sources of sugar-rich plants.

Get Price

2025-04-03· Methanol costs are a non-trivial portion of biodiesel production costs. Catalyst. A catalyst is required to facilitate the reaction between the oil and alcohol. Common catalysts used in small-scale biodiesel production are sodium hydroxide (lye) and potassium methoxide. Small-scale biodiesel producers select a catalyst based on equipment

Get Price

Our state odisha is also a major producer of non- edible oil seeds. So attempts are being taken to investigate the suita-bility of Karnja, Jatropha, Simarouba, Ma for hua&Polanga biodiesel production and to compare the properties of non-edible oil and biodiesel produced from it with dies el. Plant Description . Karanja

Get Price

Biodiesel production from non-edible plant oils. Ivana B. Banković-Ilić, Olivera S. Stamenković and Vlada B. Veljković. Renewable and Sustainable Energy Reviews, 2012, vol. 16, issue 6, 3621-3647 . Abstract: Because of biodegradability and nontoxicity biodiesel has become more attractive as alternative fuel. Biodiesel is produced mainly from vegetable oils by transesterification of

Get Price

Non-edible plant oils have been found to be promising crude oils for the production of biodiesel. World annual petroleum consumption and vegetable oil production is about 4.018 and 0.107 billion tons, respectively [1]. The cost of biodiesel and demand of vegetable oils can be reduced by non-edible oils, instead of vegetable oil. Biodiesel is a

Get Price

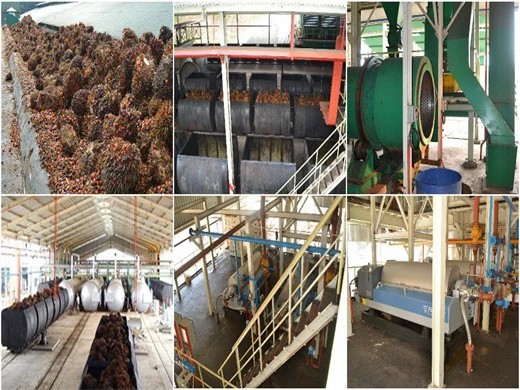

The biodiesel can be manufactured from Crude Palm Oil. The other oil sources are all the non edible oils, a few of them are Jatropha oil, Neem Oil, Karanja Oil, Mahua Oil, etc. Also used frying (cooking) oils can be used for bio diesel production. Specialty of SHREEJI’s Bio diesel plants

Get Price

It is reported that nearly 70%–95% of the total cost of biodiesel production arises from the cost of raw material; i.e., vegetable oil or animal fats. The cost of biodiesel can be reduced if we use available, non-coasted, unused biomass such as non-edible oils as frying oils, acid oils and agriculture waste oils instead of edible oils.

Get Price

Agro-industry residues such as slaughterhouse waste, restaurant cooking oil, non-food-grade virgin oil or agricultural surplus once destined for a landfill is a commodity in the biodiesel business. On a national level, biodiesel incorporated in the energy mix will encourage new business opportunities, greater investment, employment, and provide a new energy alternative.

Get Price

The plants will use waste oil, fatty acid and non-edible vegetable oil as a feedstock and the biodiesel will be blended with the HSD oil for running the trains the report says. The use of biodiesel is expected to ear the railways Rs20 million a year in carbon credits. The Railways currently consumes 2.2 billion litres of diesel a year.

Get Price

oils (both edible and non-edible) and animal fats. It has been found suitable for use as a blending bio-diesel fuel in diesel engines [6]. India is the most abundant resources of non-edible plant which could be utilized for the biodiesel production. Biodiesel is one of the most attractive

Get Price

2016-02-17· The carbon released from the burning of biofuels is continually cycled rather than being released from ancient fixed carbon sources, as is the case for fossil petroleum and natural gas. The problem is that the cost of production of fuels from lignocellulose and plant oils is high and this nascent industry cannot compete with oil prices.

Get Price

Moreover, edible oils’ feedstock costs are far expensive to be used as fuel. Therefore, production of biodiesel from non-edible oils is an effective way to overcome all the associated problems with edible oils. However, the potential of converting non-edible oil into biodiesel must be well examined. This is because physical and chemical

Get Price

Biodiesel is an alternative renewable fuel that has properties comparable to diesel obtained from petroleum processing. The major objective of the present investigations was to select the best available feedstock’s for oil production from available non-edible plant oils. The bio-diesel of Jatropha, Mahua, Karanj, Jojoba and Neem were compared

Get Price

2017-11-22· In a non-edible vegetables oils evaluation, Atabani et al. listed more than 50 useful plants for biofuel production, ranging from all over the world. Generally talking non-edible oil crops are well adapted to arid conditions and require little fertility and moisture to grow.

Get Price

purposes such as biodiesel production. Moreover, these oils could be more expensive to use as fuel. Hence, the contribution of non-edible oils such as jatropha and soapnut will be significant as a non-edible plant oil source for biodiesel production. Jatropha is grown in marginal and waste lands with no possibility of land use competing with food

Get Price

biodiesel production (SEBP) plant using locally produced oilseeds as feedstock and a crude oil biodiesel production (COBP) plant using imported crude vegetable oil as feedstock. The capital investment for a SEBP plant ranges between R110 and R145 million while a COBP plant would require a capital investment of about R45 to R50 million. These amounts include a working capital of about

Get Price

Production and Characterization of Biofuel from Non-Edible Oils: An Alternative Energy Sources to Petrol Diesel 173 1.1. History of biodisel The name ‘biodiesel’ has been given to transesterified vegetable oil to describe its use as a diesel fuel. Transesterification of triglycerides in oils is not a new process. Scientists E. Duffy

Get Price

from any vegetable oils (edible or non-edible), animal fats or special strains of microalgae [9]. Microalgae has been considered recently as a prom- ising biomass feedstock with great potential for biodiesel production [10] because they reproduce themselves every few days (2 or 3 weeks), yield oil exceeding 10x the

Get Price

The purpose of this chapter is to consider the employment of non-comestible oils into biodiesel production, to present the various processes of oil extraction and oil conversion with emphasis on the transesterification, and, finally, to highlight several uses of biodiesel in the world.

Get Price

2025-04-03· Waste oil and grease can be collected from restaurants to produce biodiesel. While the processing costs of this urban source are higher per gallon than the processing costs of virgin vegetable oil, the cost of the feedstock is generally low and sometimes free. Animal Fats. Animal fats are low-cost biodiesel feedstocks. However, there are some

Get Price

Plant oils from Ratanjyot (Jatropha curcas), Karanj (Pongamia pinnata), Neem (Azadirachta indica), and Mahua (Madhuca longifolia var. latifolia) etc. have been extracted and exploited as non-edible feedstock for the bio-diesel production in India. Our efforts have been converted to find area specific non-edible feedstock. With this point, Balanites roxburghii (BR) plant with high oil content

Get Price