Palm Oil Refinery Plant : TINYTECH Palm Oil Refinery Plant: Palm Oil is largely produced in equatorial belt, with Malaysia and Indonesia being the leading producers. Crude Palm Oil is dark in color and to make it edible it has to be refined. The Tinytech Palm Oil Refinery Plant is best suitable to refine the palm oil. Our palm oil refinery ...

Cooking Oil Refinery Plant : TINYTECH Cooking Oil Refinery Plant: Tinytech Cooking Refinery Plant is a durable, reliable and robust unit for getting the ready to use cooking oil. Cooking oil refining is an important process which is carried out after the oil is extracted from oil mill machinery and oil mills. The output of oil mill is treated ...

Get Price

The Privatization & Public Enterprises Supervising Agency (PPESA) finally got the ball rolling towards setting up a new state enterprise; an edible palm oil refinery at a projected cost of 401.1 ...

Get Price

Our cooking oil refinery plant refines crude vegetable oils extracted from soya, palm, sunflower, canola seeds, etc. to covert them to edible oils. Process tons of vegetable crude oil in shorter times.

Get Price

VIVEK CHEM FABS is a trusted Manufacturer, Exporter, Importer, service provider Fabricator & Supplier of a qualitative range of Industrial Process Plant, Edible Oil Refinery Plant, Industrial Plant Equipment, Pressure Vessel, Reactor Vessel, Agitator Tank, Stainless Steel Tank, Stainless Steel Tank Vessel, Sugar Melting Tank Tray etc. Our entire range of industrial and process equipment is ...

Get Price

2012-07-22· The edible oils are obtained from the likes of palm oil, soya bean oil, canola oil, corn oil, rape seed oil and others. In other words, the oil refinery process oil that cannot be consumed by human being while the edible oil refinery process oil that is edible (can be consumed by human beings).

Get Price

Sunflower and Rice Bran oil normally contain waxes compared to other oil. Therefore these oils are subjected to de-waxing process called Winterisation Plant, to remove waxes from oil and to produce sparkling good quality edible oils. To remove the wax, the oil is first processed in Crystaliser where it is cooled by Chilled water circulation ...

Get Price

Blanching Edible Oil Machine,Mini Soybean Mustard Edible Oil Refinery Extraction Plant Cost In India,Bran Machine Oil Rice_OKCHEM

Get Price

Adani Wilmar Ltd., known for its Fortune brand of vegetable oils, has planned to set up a large scale edible oil refinery at Dhamra in Odisha's Bhadrak district. The company intends to invest Rs. 600 crore on the refinery with an envisaged capacity of 1600 tonne per day

Get Price

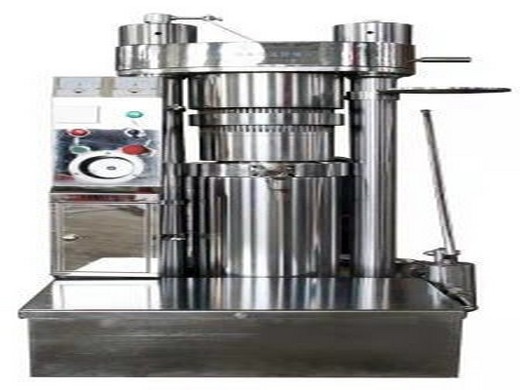

Full-continuous edible oil refinery plant (30-1000tpd): General speaking, for 30tpd and above, the full-continuous edible oil refinery plant is much better for large scale edible oil refinery plant. Though the cost of full-continuous edible oil refinery plant is high, the quality is much more steady and average. The whole edible oil refining

Get Price

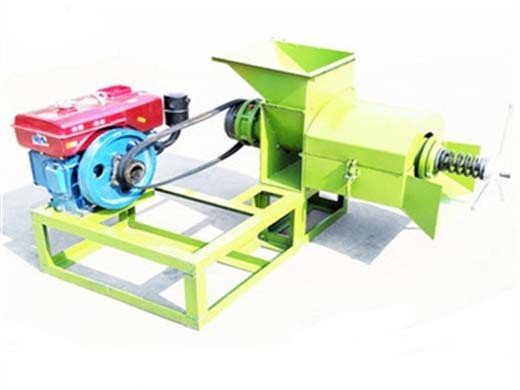

Edible Oil Refining Video: How the small scale oil refinery works? The following video is about a small scale edible oil plant set up in India, which includes both oil pressing machine and oil refining machine. This factory is built for processing mustard seeds. View the video below to see how the small edible oil refining unit works.

Get Price

Edible oil refinery plant and edible oil refining process. Edible oil refining technology used in edible oil refinery plant is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils.

Get Price

REFINING PROCESS. Chemical refining, also known as caustic and alkali processes used in refining system. Process steps; degumming, neutralization, bleaching, winterization and, deodorization. The aim of refining is to remove that phospholipids, gums, free fatty acids, metal and soaps, high temperature melting components present in small quantities, volatile compounds (mainly ketones and

Get Price

2015-01-03· The equipment is the main cost of establishing an oil refinery. Here is some references for you about the price of crude oil refining machine: * For starting a 5 ton/day edible oil refinery plant, the equipment cost is around $50,000. * For starti...

Get Price

Refining of edible oils: A critical appraisal of current and potential technologies Article (PDF Available) in International Journal of Food Science & Technology 50(1) · September 2014 with

Get Price

EDIBLE OILS & FATS REFINING OILSEDIBLE AND FATS REFINING The most frequent and important application of oily seeds and natural fats is by far in the field of edible products.Gianazza International has been active in the manufacture of edible oil refining plants for over one century and now it is engaged in the development of advanced technologies and optimization of the ones already available

Get Price

Project Reports on Edible Oils Projects . NIIR PROJECT CONSULTANCY SERVICES (NPCS) is a reliable name in the industrial world for offering integrated technical consultancy services. NPCS is manned by engineers, planners, specialists, financial experts, economic analysts and design specialists with extensive experience in the related industries.

Get Price

Edible oil refining is normally a high volume, continuous operation. The reagent additions are traditionally carried out using low shear static mixers or inline agitators, which can lead to several potential problems: The acid and sodium hydroxide solutions make up only a small fraction of the total product, and must be reduced to the smallest possible droplet size to ensure intimate contact

Get Price

Refining operations Petroleum refining processes and operations can be separated into five basic areas: • Fractionation (distillation) is the separation of crude oil in atmospheric and vacuum distillation towers into groups of hydrocarbon compounds of

Get Price

production. Chart 1 provides a breakdown of the world’s edible oil production in 2009. Chart 1: World Edible Oil Production In 2009, palm oil and soybean oil accounted for 33 percent and 28 percent of world production, respectively. Following the May 24, 2010 launch of U.S. Dollar Cash‐Settled Crude Palm Oil futures, you

Get Price

Innovative Power Distribution for the Edible Oils Industry Cost-effective and reliable power distribution Answers for infrastructure. Totally Integrated Power. 2 Requirements and Trends in the Edible Oils Industry The demand for vegetable oils and fats is growing steadily. The reason for this increased demand lies both in the popularity of convenience food and in rising population numbers. A

Get Price

We operate edible oil processing and refining facilities in the U.K., Mozambique, Nigeria and Gabon. These facilities, along with our oil palm plantations in Gabon, support our integrated palm oil supply chain and to date, 3 of our facilities in the U.K. and Gabon have achieved RSPO certification.

Get Price

The cost of setting up an edible oil refinery plant is affected by many factors including edible oil refinery plant construction cost . edible oil refinery plant cost, edible oil refinery plant transportation cost, the engineers salary cost, the worker's wage cost,crude edible oil cost, electricity, water, fuel costs, etc.; if you want to know the detail costs of edible oil refinery plant

Get Price

An industry pioneer in using the mammoth pump concept for edible oil refining, JJ-Lurgi has come a long way in the processing of edible oils. Our innovative concepts are developed in-house and in partnership with our clients, using advanced technology to deliver the most cost-effective plants with low utilities consumption and high-quality refined oils.

Get Price

Our edible oil machinery is suitable for crushing and refining of all types of oil seeds such as groundnut, sunflower, soyabean, palm kernel, mustard, copra, sesame seed, rapeseed, linseed, cotton seed, hempseed, canola etc. All the plants will be undertaken based on complete turnkey system to

Get Price

Edible/vegetable oil refining is a step by step process. Refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. The entire oil refining plant process comprises degumming/neutralization, bleaching, deodorization, and winterization.

Get Price

Cooking oil making machine manufacturer supplies high quality low cost price cooking oil processing machine, edible oil refinery machine. Offer turn-key service for vegetable oil processing plant projects.

Get Price

We offer 211 edible oils list products. There are 131 edible oils list suppliers, mainly located in Asia. The top supplying countries or regions are China, India, and Ukraine, which supply 92%, 5%, and 2% of edible oils list respectively. Edible oils list products are most popular in Africa, Domestic Market, and Northern Europe. You

Get Price

CynerSorb adsorbents for cost effective refining and purification of edible oils, biodiesel and oleochemicals. CynerSorb adsorbents reduce total powder usage, enabling longer filtration cycles and therefore increasing product yield through reduced product losses in the spent cake. CynerSorb diatomite products are highly permeable adsorbents

Get Price

Cost of Mini/Small Oil Refinery Plant Setup The main cost for mini or small scale oil refinery plant mainly include three parts, the equipment cost, transportation cost, installation and commission cost. A reliable supplier of your oil refining equipment will help you a lot on reducing the total cost since most of the reliable suppliers will

Get Price

EDIBLE OIL PRODUCTION PROCESS. The production of edible oil includes through all processes required to remove structure within the seeds and make oil suitable for sale.We specialize in many areas such as customer preferences, chemical knowledge, production acceleration techniques to perform these processes efficiently.

Get Price

comoros mobile soya oil refinery plant in columbia edible oil refinery in plants united arab emirates . manufacture 1tpd palm kernel oil refinery plant low cost price in malta . malaysia 150tpd sunflower coconut edible refining oil refining line

Get Price

As the demand for edible oil quantity and quality keep growing, more and more businessman are interested in setting up a medium cooking oil refinery plant. In fact,many factors need to be thinked.The first factor is the cost of a medium cooking oil refinery plant.

Get Price

Edible oil manufacturers face the constantly growing challenges of low margins, fluctuating raw materials quality and changing consumer habits. Improving production performance and driving down operations costs calls for innovative measurement technology. Through targeted and consistent optimization of the refining process, plant operators can

Get Price

We offer 274 edible oil refinery plant cost products. About 98% of these are oil pressers. A wide variety of edible oil refinery plant cost options are available to you,

Get Price

Production of edible oil with LEWA diaphragm metering pumps To supply the global demand for edible oil, about 40 different plants are used for the generation of edible oil. Depending on the region, a wide variety of seeds and fruit are used. The basis for these seed oils include soy beans, rapeseed, sunflowers, peanuts, palm seeds or flax seeds

Get Price

production of oil extracted from imported seeds amounted to ~0.7m tons. Remaining 2.9m tons of edible oil is directly imported. Palm oil is the major raw material, followed by soybean, sunflower and canola. Edible oil imports cost more June, 2025 Edible Oil Industry JCR-VIS Credit Rating Company Limited

Get Price

2012-07-22· The edible oils are obtained from the likes of palm oil, soya bean oil, canola oil, corn oil, rape seed oil and others. In other words, the oil refinery process oil that cannot be consumed by human being while the edible oil refinery process oil that is edible (can be consumed by human beings).

Get Price