We offer 2,298 continuous oil refining products. About 36% of these are Machine Oil Purifier, 40% are Oil Pressers. A wide variety of continuous oil refining options are available to you,

This is fully continuous,no need wash oil.No smell,no air pollution,no noise.The latest continuous-feed system has a much bigger process capacity since it doesn’t require the starting and the stopping in the pyrolysis reaction circle. The increased automation clearly has the big advantage of reduced downtime, reduced labor cost and increased efficiency over the batch feed generation

Get Price

Continuous oil refinery plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This continuous oil refinery plant is bit expensive than batch type oil refinery plant but it provides superior quality refined oil along with automation system and low processing cost.

Get Price

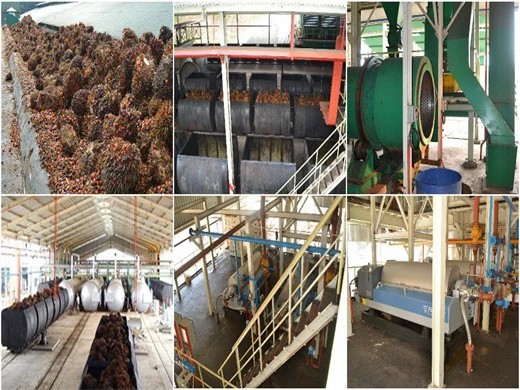

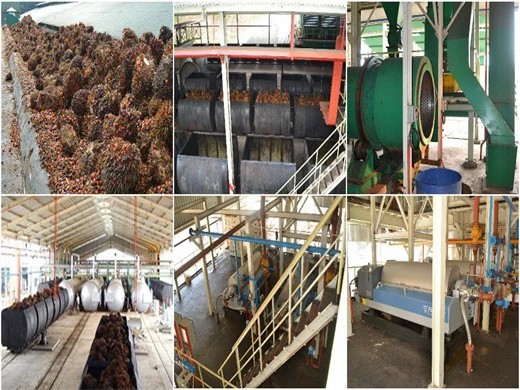

The continuous palm oil refinery plant adopts physical refining method. In this video, degumming and decolorization of palm oil are showed step by step. In this video, degumming and decolorization ...

Get Price

This 50tpd continuous soybean oil refing machine is designed for continuous operation. Continuous soybean oil refining machine is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This continuous soybean oil refining process line including unique degumming, deacidification, decolorization, negative bleaching ...

Get Price

Garbage plastic to oil batch type waste tyre/plastic pyrolysis machine Pyrolysis oil refining machine Waste engine oil refining equipment Waste Gear Oil Recycling Machine Used Fuel Oil Purification Machine Continuous waste tire pyrolysis equipment Continuous waste rubber pyrolysis equipment Continuous waste plastic pyrolysis equipment

Get Price

Continuous groundnut oil refining plant utilizes physical oil refining method to make extracted crude groundnut oil into first grade groundnut oil. The advanced equipped continuous groundnut oil refining plant is low refining loss rate, and high oil yield rate.

Get Price

Semi-continuous refining process is suitable for small and medium-sized oil plant. Technological characteristics of semi-continuous refining process: 1. Refining rate of semi-continuous refining process is higher than intermittent production process. 2. Less equipment investment and quick effect. 3. The process is simple, easy to operate.

Get Price

Continuous distillation is a process in which a chemical mixture is continuously fed into a distillation column where its contents are separated through selective boiling. It is used extensively in crude oil refining to produce petroleum products, such as gasoline, lubricants, fuel oil, waxes, and petrochemicals. In this short blog, we outline the steps by Keep reading...

Get Price

We offer 2,692 continuous equipment oil refining products. About 20% of these are machine oil purifier. A wide variety of continuous equipment oil refining

Get Price

We offer 2,298 continuous oil refining products. About 36% of these are Machine Oil Purifier, 40% are Oil Pressers. A wide variety of continuous oil refining options are available to you,

Get Price

Continuous oil refinery plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This continuous oil refinery plant is bit expensive than batch type oil refinery plant but it provides superior quality refined oil along with automation system and low processing cost.

Get Price

We offer 3,923 continuous oil refinery machine products. About 28% of these are Machine Oil Purifier, 3% are Other Rubber Processing Machinery, and 63% are Oil Pressers. A wide variety of continuous oil refinery machine options are available to you,

Get Price

We offer 3,263 continuous oil refining machine products. About 55% of these are oil pressers, 29% are machine oil purifier, and 1% are other food processing machinery. A wide variety of continuous oil refining machine options are available to you, such as automatic, semi-automatic.

Get Price

2025-02-19· The continuous palm oil refinery plant adopts physical refining method. In this video, degumming and decolorization of palm oil are showed step by step. In this video, degumming and decolorization

Get Price

Odifei Machinery manufacturing co. ltd founded in 2001 with the factory size of 10,000 Square Meter, 4 sub-companies and over 100 employees including managements, the sales and the engineers. Our continuous waste tire pyrolysis plant and continuous used oil refining plant are the real innovative development. It largely reduced downtime and increased the pyrolysis efficiency.

Get Price

This 50tpd continuous soybean oil refing machine is designed for continuous operation. Continuous soybean oil refining machine is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This continuous soybean oil refining process line including unique degumming, deacidification, decolorization, negative bleaching

Get Price

Semi-continuous refining process is suitable for small and medium-sized oil plant. Technological characteristics of semi-continuous refining process: 1. Refining rate of semi-continuous refining process is higher than intermittent production process. 2. Less equipment investment and quick effect. 3. The process is simple, easy to operate.

Get Price

Full continuous refining equipment. Avocado oil, coconut oil, palm oil, etc., because of the different processing methods of raw materials, the hair oil usually has a higher acid value, and it is easy to use molecular distillation deacidification combined with intermittent degumming to carry out refining.

Get Price

Semi-continuous refining process is suitable for small and medium-sized oil plant. Technological characteristics of semi-continuous refining process: 1. Refining rate of semi-continuous refining process is higher than intermittent production process. 2. Less equipment investment and quick effect. 3. The process is simple, easy to operate.

Get Price

Continuous groundnut oil refining plant utilizes physical oil refining method to make extracted crude groundnut oil into first grade groundnut oil. The advanced equipped continuous groundnut oil refining plant is low refining loss rate, and high oil yield rate.

Get Price

Semi-continuous oil refinery is suitable for 20-100T various edible oil. According to the characteristic of the crude edible oil, the chemical way or the physical way can be chosen. Semi-continuous oil refinery line can get the best quality oil with the less running cost.

Get Price

Project Description. Continuous type oil refining is a large scale of oil refining method for edible oil production. In general, continuous type oil refining plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content.

Get Price

The semi-continuous crude oil refining machine design is based on batch type oil refining machine but higher than batch type.Compared with batch type oil refining production line, semi-continuous crude oil refining machine is more efficient. At the same time compared with fully continuous crude oil refining machine, Semi-continuous crude oil refining machine needs less investment cost.

Get Price

Application: Continuous Type Oil Refinery Plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This process line is bit expensive than batch oil refinery process but it provides superior quality refined oil along with automation system and low processing cost. It is also a large oil refinery unit.

Get Price

Continuous peanut oil refining machine 3D diagram. Henan Doing Company is a leading designer, manufacturer and exporter of edible oil refinery plant in both continuous type vegetable oil refinery plant and batch type vegetable oil refinery plant. Next you will see the continuous peanut oil refining

Get Price

China Oil Sludge Refining Equipment Getting Fuel Oil and Diesel by Fully Continuous Pyrolysis Machine, Find details about China Oil Sludge Refining Equipment, Oil Sludge Refining from Oil Sludge Refining Equipment Getting Fuel Oil and Diesel by Fully Continuous Pyrolysis Machine .

Get Price

China Continuous Cooking Oil Refining Equipment Vegetable Oil Make Machine, Find details about China Sunflower Oil Refining Machine, Soybean Oil Refining Machine from Continuous Cooking Oil Refining Equipment Vegetable Oil Make Machine .

Get Price

Typically, the edible oil refining plant can be divided into three main types: batch oil refining, semi-continuous refining and continuous refining. Choosing which type for your edible oil refining line should assess the capacity, the purpose of final refined oils and detailed refining process.

Get Price

Continuous Distillation Process in Crude Oil Refining • Honiron . Continuous distillation is a process in which a chemical mixture is It is used extensively in crude oil refining to produce petroleum products, such as Generally, sieve type or bubble cap trays are used to facilitate the stripping process. of industrial process equipment

Get Price

China Continuous Cooking Oil Refining Equipment Vegetable Oil Make Machine, Find details about China Sunflower Oil Refining Machine, Soybean Oil Refining Machine from Continuous Cooking Oil Refining Equipment Vegetable Oil Make Machine .

Get Price

China Canola Seeds Oil Continuous Refining Plant, Find details about China Continuous Edible Oil Refining Plant, Soybean Oil Refining Process from Canola Seeds Oil Continuous Refining Plant Myande Group Co., Ltd.

Get Price

Continuous palm oil physical refining process flow chart. This continuous palm oil physical refining process flow chart is based on our engineers' designing palm oil physical refining technology, which is for 100tpd continuous palm oil refinery plant project in Kenya.It is different from other oil refining process, such as soybean oil refining process, sunflower oil refining process, etc.

Get Price

We provide high quality Edible Oil Full Continuous Refining Processing machinery, best price edible oil refinery equipment supplier or manufacturer Htoilmachine.

Get Price

Oil refining workshop: Get the high-grade cooking oil from crude oil through the hydration degumming, continuous decoloring, filtering, continuous deacidifying and deodorizing 4 main sections. It’s a flexible process, economic and environmental protective.

Get Price

Products,Odifei Machinery manufacturing co. ltd founded in 2001 with the factory size of 10,000 Square Meter, 4 sub-companies and over 100 employees including managements, the sales and the engineers. Our continuous waste tire pyrolysis plant and continuous used oil refining plant are the real innovative development. It largely reduced downtime and increased the pyrolysis efficiency.

Get Price

2017-05-29· Continuous distillation is a process in which a chemical mixture is continuously fed into a distillation column where its contents are separated through selective boiling. It is used extensively in crude oil refining to produce petroleum products, such as gasoline, lubricants, fuel oil, waxes, and petrochemicals. In this short blog, we outline the steps by Keep reading...

Get Price

Typically, the edible oil refining plant can be divided into three main types: batch oil refining, semi-continuous refining and continuous refining. Choosing which type for your edible oil refining line should assess the capacity, the purpose of final refined oils and detailed refining process.

Get Price

For large capacity palm oil refining machine, the popular capacity is 100tpd, 200tpd, 600tpd, 800tpd, 1000tpd and so on. 100tpd palm oil refining machine be continuous palm oil refining machine. 100tpd palm oil refining machine has features of advanced technology, automatic control system, high equipment configuration and so on.

Get Price