Degumming process in oil refining plant is to remove gum impurities in crude oil by physical or chemical methods, and it is an oil purification process. After screw pressing and solvent extracting from oilseeds, crude oil mainly contains triglycerides and few non-triglyceride.

A: RBD palm oil can still be further processed into palm olein and palm stearin. A: To refine red palm oil, there are four steps to do: degumming, deacidification, decolorization and deodorization. A: You must heard that chemical refining technology is used for in small scale batch type edible oil refinery plant.

Get Price

After extracting palm oil, the crude palm oil is sent to palm oil refinery plant for refining. Through several refining steps to remove free fatty acids, natural pigments and odors, crude palm oil becomes refined-bleached-deodoried palm oil (RBD PO).

Get Price

For fats obtained by pressing and water, which are low in phosphatides, (20 ppm of phosphorus), such as palm oil, palm kernel oil, olive oil, the degumming process is quite simple: it suffices to mix the fat with a small quantity of a strong degumming acid such as phosphoric or citric acid to dissociate the nonhydratable phosphatides (NHP) into phosphatidic acid (PA) and calcium or magnesium bi-phosphate salt.

Get Price

This 30TPD palm oil refinery plant belongs to semi-continuous edible oil refinery plant, with chemical refining method of edible oil. Its degumming, deacidification, decolorization sections are same as batch type edible oil refinery plant, but deodorization section is same as full-continuous edible oil refinery plant, using deodorization tower

Get Price

Palm Oil Physical Refining Process. Oil physical refining process, also called as oil steam refining. During the degumming section in the palm oil milling plant, the gum will be removed from palm oil by utilizing phosphoric acid or citric acid. Next to bleaching section, the coloring matter and other metal ions will be absorbed or removed.

Get Price

Degumming is the first process in the vegetable oil refining which commences with the heating of crude oil. The feedstock is taken into the degumming vessel where the temperature of oil is raised slowly. The main purpose of degumming is to remove the Phospholipids / Gums from the crude vegetable oils.

Get Price

Degumming process in oil refining plant is for removing gum impurities from crude oils. Common methods are hydrated or acid degumming.

Get Price

The purpose of palm kernel oil refining is to remove impurities in crude edible oil.During palm kernel oil refinery process, we adopts water hydration degumming, alkali neutralization or steam distillation deacid, adsorption decolorization.

Get Price

A: Usually, in palm kernel oil refining plant, there are four steps to refine palm kernel oil: degumming, deacidification, decolorization and deodorization. Only all the steps are qualified, you can get high quality refined palm kernel oil.

Get Price

For fats obtained by pressing and water, which are low in phosphatides, (20 ppm of phosphorus), such as palm oil, palm kernel oil, olive oil, the degumming process is quite simple: it suffices to mix the fat with a small quantity of a strong degumming acid such as phosphoric or citric acid to dissociate the nonhydratable phosphatides (NHP) into

Get Price

This 30TPD palm oil refinery plant belongs to semi-continuous edible oil refinery plant, with chemical refining method of edible oil. Its degumming, deacidification, decolorization sections are same as batch type edible oil refinery plant, but deodorization section is same as full-continuous edible oil refinery plant, using deodorization tower

Get Price

Photos about this project are listed below. Feel free to contact us if need more details of our palm oil mill plant, palm oil refinery plant , palm kernel oil mill plant, and you are also welcome to tell us your plan and let us help you start your own palm oil plant.

Get Price

Refinery palm oil process is mature technology in China. The purpose of refinery palm oil process is to removal the impurities to meet the standards of edible oil. And the refinery palm oil processes are: crude oil ---degumming bleaching---deodorization---fractionation. Steps of refining process of palm oil are as follows:

Get Price

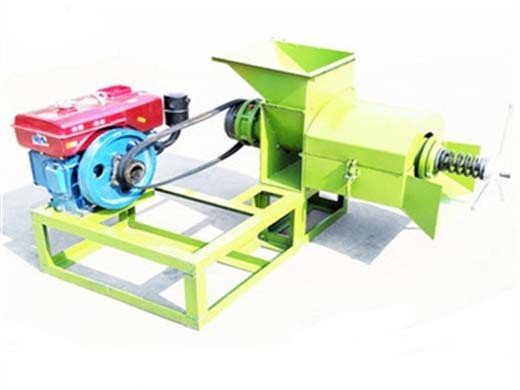

Wide Application: can process various kinds of crude oil, including all kinds of vegetable oil, seeds oil and palm oil. It is the best choice for small refinery of cooking oil and salad oil.

Get Price

Refining is an essential process for a complete palm kernel oil processing process because there are still some impurities such as phospholipids, FFA, pigment, odor, etc. in the crude palm kernel oil.In order to gect high quality palm kernel oil and let palm oil is good for long time storage .

Get Price

This 30TPD palm oil refinery plant belongs to semi-continuous edible oil refinery plant, with chemical refining method of edible oil. Its degumming, deacidification, decolorization sections are same as batch type edible oil refinery plant, but deodorization section is same as full-continuous edible oil refinery plant, using deodorization tower

Get Price

Oil Refining is a progress of removing the impurities such as phospholipids, FFA, pigment, off-flavor in cruel oil before edible application. Oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining equipment.

Get Price

For fats obtained by pressing and water, which are low in phosphatides, (20 ppm of phosphorus), such as palm oil, palm kernel oil, olive oil, the degumming process is quite simple: it suffices to mix the fat with a small quantity of a strong degumming acid such as phosphoric or citric acid to dissociate the non-hydratable phosphatides (NHP) into phosphatidic acid (PA) and calcium or magnesium bi-phosphate salt.

Get Price

Palm kernel oil refining process/crude oil refining machine. Manufacturing Palm kernel oil refining process/crude oil refining machine,The purpose of palm kernel oil refining process is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality oil produces.

Get Price

Photos about this project are listed below. Feel free to contact us if need more details of our palm oil mill plant, palm oil refinery plant , palm kernel oil mill plant, and you are also welcome to tell us your plan and let us help you start your own palm oil plant.

Get Price

In order to remove the above impurities, the oil goes to the refinery plant in order to receive the RBD Palm Oil (Refined Bleached & Deodorized). After refining of the palm oil the RBD oil goes to the fractionation section in order to get the palm olein and stearin.

Get Price

Deodorizing is the final stage in edible oil refining in order to remove odoriferous material, free fatty acids and other undesired minor components by steam distillation under condition of high temperature and vacuum to produce a bland oil with a good shelf life. 5.

Get Price

Palm kernel oil refining process usually includes degumming, deacidification, decolorization, deodorization and fractionation. Palm oil refining classification is based on different uses and requirements, the use of physical methods and chemical processes, removal of crude palm oil harmful impurities and unnecessary substances, get some

Get Price

The first step of crude palm oil and palm kernel oil physical refining is the degumming, which consists of the removal of the phosphatides. When this content is low, as is the case for these oils, the dry degumming is the common way.

Get Price

Refining is an essential process for a complete palm kernel oil processing process because there are still some impurities such as phospholipids, FFA, pigment, odor, etc. in the crude palm kernel oil.In order to gect high quality palm kernel oil and let palm oil is good for long time storage .

Get Price

Palm kernel oil refinery plant for sale, Palm kernel oil refinery process line adopts the most advanced crude oil refining technology including degumming, deacidification, decolorization, negative blenching, high vacuum steam deodorization, dewaxing and dehydration.

Get Price

This 30TPD palm oil refinery plant belongs to semi-continuous edible oil refinery plant, with chemical refining method of edible oil. Its degumming, deacidification, decolorization sections are same as batch type edible oil refinery plant, but deodorization section is same as full-continuous edible oil refinery plant, using deodorization tower

Get Price

KMEC is a reliable Crude Oil Refinery Plant Manufacturer, offering various edible oil refinery machine at factory price.. Oil degumming is the first step in an oil refinery plant and is key to the vegetable oil refining process.Oil degumming is performed in two ways: hydration oil degumming and special oil degumming. Hydration Oil Degumming

Get Price

Photos about this project are listed below. Feel free to contact us if need more details of our palm oil mill plant, palm oil refinery plant , palm kernel oil mill plant, and you are also welcome to tell us your plan and let us help you start your own palm oil plant.

Get Price

The quality of crude palm oil is dependent on the care taken after harvesting, particularly on the handling of the FFBs. Figure 1. Fresh fruit bunches waiting for processing at palm oil mill. A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 60-100 tons

Get Price

Palm Oil Refining Degumming and Deacidification Section Introduction: Washing: there is still about 500ppm soap in the neutralized oil from the separator. To remove the remaining soap, add into the oil about 5~8% hot water, with water temperature 3~5 閳?higher than the oil generally.

Get Price

Palm kernel oil is indeed highly saturated compared to palm oil; the saturated fatty acid content is generally above 80% in palm kernel oil while it is only 閳?0% in palm oil. Mono-unsaturated fatty acids count for 閳?0% and 閳?5% and poly-unsaturated for 閳?0% and 閳?%, respectively, in palm and palm kernel oils.

Get Price

Palm oil and palm kernel oil have sprought rapidly in the edible oil market in recent years. Palm kernel oil contains more unsaturated fatty acid and has high iodine number. Except for cooking, it can be divided into solid state and liquid state through crystallizing and pressing.

Get Price

This 30TPD palm oil refinery plant belongs to semi-continuous edible oil refinery plant, with chemical refining method of edible oil. Its degumming, deacidification, decolorization sections are same as batch type edible oil refinery plant, but deodorization section is same as full-continuous edible oil refinery plant, using deodorization tower

Get Price

When phosphatide content is low, as is the case for palm oil, palm kernel, coconut, and tallow, dry degumming is the common way. Typical composition of the main components of Malaysian crude palm oil (CPO) is shown below. Note the phosphorus content in the oil.

Get Price

Palm kernel oil refining process/crude oil refining machine. Manufacturing Palm kernel oil refining process/crude oil refining machine,The purpose of palm kernel oil refining process is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality oil produces.

Get Price

Photos about this project are listed below. Feel free to contact us if need more details of our palm oil mill plant, palm oil refinery plant , palm kernel oil mill plant, and you are also welcome to tell us your plan and let us help you start your own palm oil plant.

Get Price

Oil Degumming. Home > Products and Services We Offer > Vegetable Oil Refinery >. KMEC is a reliable Crude Oil Refinery Plant Manufacturer, offering various edible oil refinery machine at factory price. Oil degumming is the first step in an oil refinery plant and is key to the vegetable oil refining process.

Get Price