Palm Oil Mill Plant Flow Chart Introduction: 1.Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge. 2.Palm oil mil process of sterilization: the use of high temperature to cook soft fruit bunches and sterilization, easy to separate fruit bunches, soft fruit, increasing the humidity of ...

At here you will see palm oil press machine, palm oil mill plant, palm oil processing machine, palm oil refining machine running video as well as small palm oil mill plant, samll palm oil refinery plant 3D animation ... Peru 20tpd olive oil refinery plant debugging and running.

Get Price

Crude Palm Oil Mill Process Introduction:. 1.Weighing.Palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.Loading ramp.FFB after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank.

Get Price

1.Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge. Palm oil mil bunch reception. 2.Palm oil mil process of sterilization: the use of high temperature to cook soft fruit bunches and sterilization, easy to separate fruit bunches, soft fruit, increasing the humidity of the fruit, it is ...

Get Price

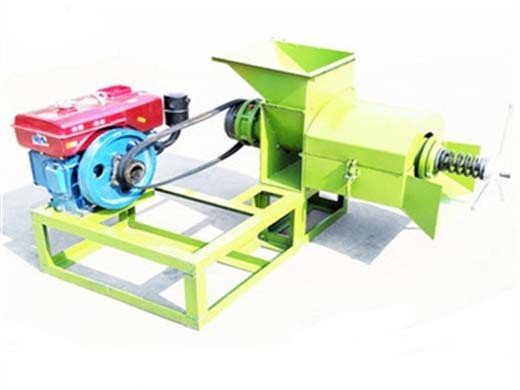

Mini Palm Oil Processing Plant. The above palm oil processing unit is designed for 1-20 ton/day mini palm fruit processing factory. The main equipments include palm fruits sterilizer, thresher, screw palm oil machine, conveyor and tower crane. For 20-100 ton/day small to medium scale palm oil mill, you can take the following project for reference.

Get Price

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines - biochemistry, chemical and mechanical engineering - and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a ...

Get Price

The quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the FFBs and the process adopted. A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 2.5 - 150 MT FFB/hr.

Get Price

5tpd vegetable oil refining machine installed in Indonesia for refining crude palm oil (CPO) 20TPD edible oil refining machine installed in Peru for refining olive oil; Large scale cooking oil mill plant's equipment showing video; Edible oil solvent extraction plant video with real project running video; View All

Get Price

Palm oil mill process is quite different from other oil seeds processing. Palm oil mill process includes 6 parts: Palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery.Our palm oil mill process is low cost and energe-saving.

Get Price

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

Get Price

Palm oil, like all fats, is composed of fatty acids, esterified with glycerol. Palm oil has an especially high concentration of saturated fat, specifically the 16-carbon saturated fatty acid, palmitic acid, to which it gives its name. Monounsaturated oleic acid is also a major constituent of palm oil.

Get Price

Palm Oil Mill Plant Flow Chart Introduction: 1.Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge. 2.Palm oil mil process of sterilization: the use of high temperature to cook soft fruit bunches and sterilization, easy to separate fruit bunches, soft fruit, increasing the humidity of

Get Price

Palm oil is derived from the flesh of the fruit of the oil palm species E. Guineensis. In its virgin form, the oil is bright orange Read more. Palm Oil Plantation. The Oil Palm Tree. The Oil. Health & Nutrition. Palm Oil & The Environment. The Tree of Life. Palm Oil Industry. Palm Oil Industry. Industry Overview. Malaysian Palm Oil Industry. Processing Flow Chart. Market Statistic & Prices

Get Price

A palm oil mill produces crude palm oil and kernels, as primary products and biomass as secondary product. The capacity of mills varies between 60- 100 tons F

Get Price

solids entirely from the palm oil. The oil is then dehydrated in a vacuum drier and put into storage. The slurry can be mixed with the empty fruit bunches and be composted. If the palm oil mill has a demand or a market for biogas/ energy, the POME (sterilizer condensate and decanter biomass) can be treated in a biogas plant. For this kind of

Get Price

Palm oil mill process is quite diffferent from other oil seeds processing, such as the soybean,peanut etc. Palm fruits consists a lot of fatty acid enzyme, which would hydrolyze palm oil. That's the reason why palm fruit must be sent into processing in 24 hours.

Get Price

Mini Palm Oil Processing Plant. The above palm oil processing unit is designed for 1-20 ton/day mini palm fruit processing factory. The main equipments include palm fruits sterilizer, thresher, screw palm oil machine, conveyor and tower crane. For 20-100 ton/day small to medium scale palm oil mill, you can take the following project for reference.

Get Price

In the palm oil milling operation, depending on the efficiency of the mill, a substantial part of the contained oil can be lost in the effluent stream. Therefore, an intervention at any processing stage that increases recoverable oil and reduces oil in the discharged palm oil mill effluent is expected to improve palm milling performance.

Get Price

Recommendations on good agricultural practices for oil palm are aimed to provide growers to practice every step of production processes starting from cultivation to transportation of oil palm bunches to collection center (ramp) or mill and to ensure good quality and safe oil palm bunches produce suitable for production of palm oil. The details

Get Price

Furthermore, in-depth investigations were conducted to optimize the processing procedures and oil palm fruit conditions that will produce improved palm oil products that meet international

Get Price

There, the remaining oil is recovered, while palm oil mill effluent (POME) and solid waste are separated. The latter can be used as organic fertilizer in the plantation. Palm Kernel Crushing Plant. After digestion of the palm fruit and extraction of the palm oil from the mash, the nuts and fibers are recovered. First they are dried and

Get Price

When asked about Palm Oil Processing Machines in Nigeria, I can help but feel nostalgic as memories of those old manual palm oil press comes to mind. The vision of two people turning the corkscrew with sheer brute force alone, while palm oil slowly sips into a

Get Price

Long ago, there weren't many fabricators of Palm Oil Milling Machine in Nigeria, the process of palm oil and kernel oil extractions has was a slow and tedious process.. Although some millers still hang on to the old tedious ways, there are now tools and machines available to make the process smooth.

Get Price

Palm oil mill manufacturer in Nigeria, Malaysia and Indonesia. We are a leading palm oil mill manufacturer that provides advanced palm oil machines, efficient palm oil mill plant and professional palm oil mill turnkey service with good price for the worldscustomers, such as

Get Price

Palm oil mill/palm oil extraction machine runing video.palm oil mill process palm &Palm fruit to cooking oil video.palm oil mill machinery production video.

Get Price

Introduction of the Palm Oil Milling Process Fresh Fruit Bunch Palm oil (CPO, Crude Palm Oil) is extracted from FFB (Fresh Fruit Bunch) by mechanical process, where a mill commonly handles 45 to 100 mt per hour of FFB.The modern palm oil mill of today is based predominantly on concepts developed in the early 50s.

Get Price

Palm Oil Mill Process Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. It is very useful to know palm oil mill processing

Get Price

Introduction of the Palm Oil Milling Process Fresh Fruit Bunch Palm oil (CPO, Crude Palm Oil) is extracted from FFB (Fresh Fruit Bunch) by mechanical process, where a mill commonly handles 45 to 100 mt per hour of FFB.The modern palm oil mill of today is based predominantly on concepts developed in the early 50s.

Get Price

Palm Oil Mill Process Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. It is very useful to know palm oil mill processing

Get Price

Palm oil production is vital for the economy of Malaysia, which is the world's second- largest producer of the commodity after Indonesia. The Malaysian Palm Oil Board (MPOB) is a government agency responsible for the promotion and development of the palm oil sector in the country. The country's palm oil industry produces about 90 million tonnes of lignocellulosic biomass, including empty fruit

Get Price

Palm Oil Mills and Oil Extraction Ratio Jatinder Raj* and N Ravi Menon** SYNOPSIS his article that appeared in the Engi-neering Bulletin No. 70 has summa-rised the gist of the dilemma faced by palm oil millers from day one the modern palm oil mills made their debut in

Get Price

As the world second largest palm oil producer after Indonesia, Malaysia produced a massive amount of waste from its palm oil industry annually, including kernels and husks from pressed fruits, discarded branches, and wastewater mixed with organic matter known as palm oil mill effluent (POME), The Engineer reported on 18 May.

Get Price

Flow chart of the production chain of palm oil and palm kernel oil products for food application in the EU (1) Cultivation of palm fruits Transport to the oil mill Palm fruits (2) Production of crude oil Processing of fruit bunches Drying and processing of palm kernels Palm kernels Storage and transport Crude oil (A) Transport Storage

Get Price

(trunks, fronds, shells, palm press fiber and the empty fruit bunches) are produced each year. The empty fruit bunches (EFB) represent about 9% (Lim 2000) of this total. They are the residue left after the fruit bunches are pressed at oil mills, and the oil extracted. The oil mills are located near or in the

Get Price

SALCRA is currently managing the following Palm Oil Mills; Lubok Antu Palm Oil Mill (LAPOM). Bau Palm Oil Mill (BAPOM). Saratok Palm Oil Mill (SAPOM). Serian Palm Oil Mill (SEPOM). The core businesses for all the four (4) Palm Oil Mills are to process Fresh Fruit Bunches (FFB) and to market oil palm products; Crude Palm Oil (CPO) and Palm

Get Price

PomTech. Website about P.O.M. (Palm Oil Mill) technology is born! P.O.M.Tech is designed especially for POM practicians and enthusiasts who want to know more about P.O.M. (Palm Oil Mill) technology. Handle and support by experienced POM technology practicians, people will benefit from its existence; not only for young engineers who are new to

Get Price

Processing facilities Palm oil mill and palm kernel crushing process: a brief description . Fresh fruit bunches (FFB) from the plantations are offloaded daily at the factory's offloading bay. This ramp can contain up to 600 tonnes of FFB. Before offloading, the fruit is weighed at the electronic weighbridge at the entrance gate.

Get Price