Oilseed pretreatment & pressing machines are necessary for big capacity cooking oil processing factory, which influences the processing working behind and the quality of crude cooking oil, including cleaning sieve, stones removal machine,etc.

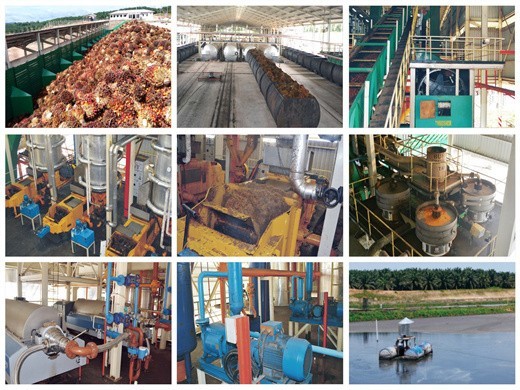

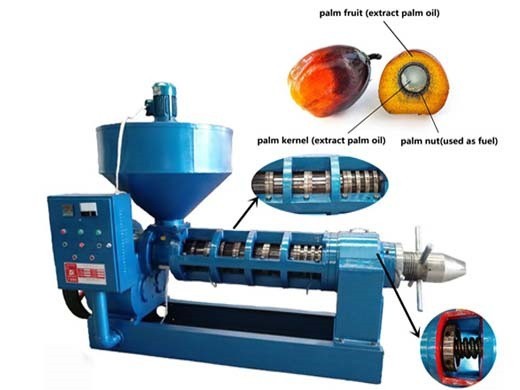

Oilseed Pretreatment and Pressing Machine Type: Oilseeds pretreatment and pressing Processing Material: soybean, sesame, corn germ, camellia seed, palm fruit etc

Get Price

Cooking is an important part of oil processing plant, which prepares for further step oil pressing process. Oilseeds cooking section utilizes steam cooking to process raw material into rip germ through wetting, heating, steaming and cooking. Cooking is one of the important sections of oil processing plant.

Get Price

Oilseed processing generally refers to the process of extracting oil from oil seeds. The whole processing begins with oilseed harvesting, and ends with oil exaction.The oilseeds pretreatment and prepress plant include cleaning section, breaking section, flaking section, softening section, cooking section and oil press section.

Get Price

Oilseed pretreatment usually means the working procedures of detaching the impurities out of the oil material to make the oilseeds in the best condition before pressing in order to extract the most oil out. It is the first and most vital step during the whole set of oil mill plant.

Get Price

oilseeds cold press pretreatment equipment Oilseed Pretreatment and Pressing Machine Oil seeds pretreatment pressing machines for sale cooking oil machine press pressing machine 130 for seeds from Oilseeds Pretreatment Machinery Global Oilseed Processing Equipment Market Report Small Oil Press Machines Processing Lines at Factory Price Various Types of Oilseeds Preatment Machines Complete

Get Price

Oil Seeds Pretreatment & Press Project Details: The technology and equipment of Oil Seeds Pretreatment & Press Project developed by are suitable for many kinds of oil seeds. Considering the characteristics of oil seed and customsrequirement, we can provide the special design to adjust oilseed to the best state, which is convenient to follow section, and easy to improve oil yield.

Get Price

Oilseeds cooking section utilizes steam cooking to process raw material into rip germ through wetting, heating, steaming and cooking. Cooking is one of the important sections of oil processing plant. The steam cooking result will directly affect the oil production process, oil yield and oil quality and cake and meal quality.

Get Price

Oilseed pretreatment usually means the working procedures of detaching the impurities out of the oil material to make the oilseeds in the best condition before pressing in order to extract the most oil out. It is the first and most vital step during the whole set of oil mill plant.

Get Price

The pretreatment for vegetable oil processing or edible oil processing usually means the working procedures of detaching impurities out of the edible or vegetable oil materials. These impurities are generally referred to as organic and inorganic impurities. The organic impurities include the stem leaf, cord, chemical fibers, velveteen and their seeds.

Get Price

The oilseed pretreatment is a series of treatments such as cleaning, shelling, peeling, crushing, conditioning, and flaking before the oil prcessing. The purpose of the utility model is to remove impurities and make them into materials with certain structural properties, so as to meet the requirements of different oil extraction processes.

Get Price

As the world leader in oilseed preparation, Crown offers three options for soybean dehulling systems: hot dehulling for plants that serve the high protein/low fiber market, warm dehulling for areas of the world that process imported beans and cold dehulling for plants with an existing preparation system that want to add dehulling to produce a

Get Price

Conditioned oilseeds are conveyed to the Oilseed Flaking Machine, a machine which ruptures the cell tissue of the seeds and increases the surface area for oil extraction. The flaking process is the essence of the oil extraction plant. Kernels entering the machine are first pressed into 0.3 millimeter flakes...

Get Price

China Yongsheng export high qaulity Oil Expeller, which including Large and Small Oil Expeller, Oil Expeller with Filter, Oilseed Pretreatment Equipment, Oil Mill Machine, Oli Pressing Machine, Oil Mill Machinery with Filter, Cooking Oil Preliminary Pressing Machine etc.

Get Price

Oilseed drying section can reduce moisture of oilseeds to suitable moisture through dehydration process. Sometimes when oilseeds harvest is during the rainy season with high moisture content, oilseeds drying process is necessary for further oil pressing.

Get Price

Oilseeds flaking section utilizes mechanical action to press oilseeds into tablets or slice. Flaking can destroy tissue of oilseeds and creates favorable conditions for oilseeds steaming and roasting in oil pressing process. Oilseeds flaking make efficient separation of oil from oil pressing machine or oil extraction process.

Get Price

The oilseed pretreatment is a series of treatments such as cleaning, shelling, peeling, crushing, conditioning, and flaking before the oil prcessing. The purpose of the utility model is to remove impurities and make them into materials with certain structural properties, so as to meet the requirements of different oil extraction processes.

Get Price

oil mill machinery of Pretreatment/Press Process, Oilseed pretreatment & pressing machines mall scale oil press machine,oil expeller machine for peanut,soybean,rapeseed,corn germ,soybean,palm oil,etc.

Get Price

Oil Production Equipment, Oil Pressing Euipment, Crusher Machine,Flaking Machine, Cooker. Language. English Chinese. Home; Oil Expeller. Large Oil Expeller. Small Oil Expeller. Oil Expeller with Filter. Oilseed Pretreatment Equipment Oil Expeller. Oil Processing Machine - Crush... Inquire Now.

Get Price

Oilseed Cleaning and Selecting. Oilseed cleaning and selecting is of great importance in the oilseed pretreatment process and later procedures. Generally speaking, oilseed cleaning can not only reduce the wear and tear of the oil processing machinery but also enhance oil yield as well meal quality.

Get Price

China Yongsheng export high qaulity Oil Expeller, which including Large and Small Oil Expeller, Oil Expeller with Filter, Oilseed Pretreatment Equipment, Oil Mill Machine, Oli Pressing Machine, Oil Mill Machinery with Filter, Cooking Oil Preliminary Pressing Machine etc.

Get Price

Oil Seed processing process always refers to the Oil Pretreatment section during the entire oil processing process. Oil Seed processing is to make the oil seeds in the best condition to process the most oil out. Oil Seed Processing Plant Workshop During the entire oil seed processing plant,...

Get Price

Oilseed drying section can reduce moisture of oilseeds to suitable moisture through dehydration process. Sometimes when oilseeds harvest is during the rainy season with high moisture content, oilseeds drying process is necessary for further oil pressing.

Get Price

Oil material puffing machine is used for pretreatment of high oil-content materials or various pre-pressed oil cakes before leaching. it is a key method to improve productivity, reduce energy consumption, improve oil quality and raise leaching rate in the edible oil processing plant.

Get Price

Oilseed Pretreatment and Pressing Machine. Corn Germ Pretreatment and Oil Pressing Machine. Oilseeds Crushing Section. Oilseeds Softening Section. Oilseeds Drying Section. Cottonseed Oil Pretreatment and Pressing Machine. Palm Fruit Oil Pressing Machine. Fragrant Peanut Oil Press Machine.

Get Price

Oil material puffing machine is used for pretreatment of high oil-content materials or various pre-pressed oil cakes before leaching. it is a key method to improve productivity, reduce energy consumption, improve oil quality and raise leaching rate in the edible oil processing plant.

Get Price

The establishment of oilseeds pretreatment depends on oilseed varieties, oil processing method, product quality standard, oilseeds utilization and invest on oil machine project etc. Oil pressing is type of simple cooking oil processing process, which includes pressing, pre-pressing, high temperature oil pressing, and cold oil pressing etc.

Get Price

The pretreatment for vegetable oil processing or edible oil processing usually means the working procedures of detaching impurities out of the edible or vegetable oil materials. These impurities are generally referred to as organic and inorganic impurities. The organic impurities include the stem leaf, cord, chemical fibers, velveteen and their seeds.

Get Price

Oilseeds Pretreatment and Pre-Press Project. Oilseeds Pretreatment and Pre-Press Project. Home; Project. Oilseeds Pretreatment and Pre-Press Project; 30T/D Sunflower seed oil press machine plant. September 28, 2015. Bottom price of oil press machine in the 118th Canton Fair in October 2015. September 25, 2015.

Get Price

As the world leader in oilseed preparation, Crown offers three options for soybean dehulling systems: hot dehulling for plants that serve the high protein/low fiber market, warm dehulling for areas of the world that process imported beans and cold dehulling for plants with an existing preparation system that want to add dehulling to produce a

Get Price

Huatai offers professional processing line of oilseed pretreatment machine, oil making machine and oil press machines. Get high quality oil from oil pressing machines.

Get Price

Oil material puffing machine is used for pretreatment of high oil-content materials or various pre-pressed oil cakes before leaching. it is a key method to improve productivity, reduce energy consumption, improve oil quality and raise leaching rate in the edible oil processing plant.

Get Price

The oilseed pretreatment is a series of treatments such as cleaning, shelling, peeling, crushing, conditioning, and flaking before the oil prcessing. The purpose of the utility model is to remove impurities and make them into materials with certain struct

Get Price

Position:Home > Products > Edible Oil Production Plant Project > Oil Seed Pretreatment and Pressing Plant Machine > Oil seed Pretreatment and Pressing Plant Oil seed Pretreatment and Pressing Plant Oil plants pre-treatment is a series of treatments including cleaning, peeling, crushing, softening, rolling embryo, puffing, damp heat treatment

Get Price

The pretreatment for vegetable oil processing or edible oil processing usually means the working procedures of detaching impurities out of the edible or vegetable oil materials. These impurities are generally referred to as organic and inorganic impurities. The organic impurities include the stem leaf, cord, chemical fibers, velveteen and their seeds.

Get Price

Pretreatment Process before Rapeseed Oil Pressing. Rapeseed oil pretreatment process is a very important part before rapeseed oil pressing.Rapeseed oil pressing has certain standard requirements for oilseed, such as water content, cleanliness requirements, shell removal, high temperature treatment, etc.

Get Price

Oil Extruding Machine. Working Principle of the Oil Extruding Machine. Oil extruding machines, including those for soybeans, transfer mechanical energy into thermal energy by forcing the material along the barrel using a screw. After discharge the seeds are heated and ready to enter the expeller, which produces the oil.

Get Price

Oilseeds Cold Press Pretreatment Equipment. Capacity 10-500T/D. Oilseed camellia seed, peanut, rapeseed, sunflower seed, walnut, castor seed, tea seed, almond, rubber seed, flaxseed. Application cold oil pressing, low temperature (lower than 60鈩? oilseed pressing . Description Cold press is suitable for high added-value oilseeds. Such as grape seed, camellia seed, walnut, almond, flaxseed

Get Price