Palm oil mill process includes 6 parts: Palm bunches receiving, sterilizer, threshing, mashing and pressing, crude oil clarifying and palm kernel recovery. 1. Palm oil mill process of fruits receiving: Collecting the ripe fresh cluster from the orchard and convey by trucks, then pour the fluster into the discharge door after weighed by ground ...

Palm oil refinery process pdf. Refining is an essential process for a complete palm oil production line because there are still some impurities such as phospholipids, FFA, pigment, odor, etc. in the crude palm oil.

Get Price

3. Widely application. The palm oil refining machine can refine soybean oil, peanut oil, sunflower oil, mustards oil,cottonseed oil, sesame oil, palm oil, palm kernel oil and other crude vegetable oil. Palm oil refining process flow chart: Palm oil refining process flow chart. Crude palm oil refinery process steps: Hydration degumming :

Get Price

In order to get the pure and refined oil, there are three main process in chemical palm oil refinery plant and chemical palm kernel oil refinery plant: degumming process, bleaching process and deodourising process.. According to the degree of automation, the refinery process can also be divided into Batch Refinery Plant, Semi-continuous Refinery Plant and Continuous Refinery Plant.

Get Price

Palm oil refinery makes the highest efficiency crude palm oil processing technology in order to make the finest extraction of palm oil. Get the best palm oil refining plant equipment design from palmoilmachine.com.

Get Price

Palm kernel oil refining process only contains four basic process of oil refining, which is different from palm oil refining process. Beside degumming, deacidification, bleaching, deodorization four basic process, there is fractionation process in palm oil refinery plant.Because the quantity portion of stearin in the palm kernel oil is very less, almost negligible, the palm stearin is ...

Get Price

Palm kernel oil refinery plant for sale, Palm kernel oil refinery process line adopts the most advanced crude oil refining technology including degumming, deacidification, decolorization, negative blenching, high vacuum steam deodorization, dewaxing and dehydration.

Get Price

Manufacturing Batch type palm kernel oil refinery plant,A batch type palm kernel oil refinery plant is the most widely used system to refine different oils. This batch type palm kernel oil refinery plant is generally used for smaller capacity plants ranging from 1 Tons per Day to 30 Tons per Day.

Get Price

Goyum India offers turnkey solutions for palm oil refinery plant, including physical refining and chemical refining of palm oil. We manufacture and supply palm oil refinery plant and machinery to process the crude palm oil.

Get Price

Refinery palm oil process is mature technology in China. The purpose of refinery palm oil process is to removal the impurities to meet the standards of edible oil. And the refinery palm oil processes are: crude oil

Get Price

Palm oil mill process includes 6 parts: Palm bunches receiving, sterilizer, threshing, mashing and pressing, crude oil clarifying and palm kernel recovery. 1. Palm oil mill process

Get Price

Palm kernel oil refinery process enjoys the same technology with other cooking oil refinery. To meet the international industry’s standards for edible oil, the crude palm kernel oil produced by palm kernel oil mills should be refined in palm kernel oil refinery

Get Price

Palm oil refinery process pdf. Refining is an essential process for a complete palm oil production line because there are still some impurities such as phospholipids, FFA, pigment, odor, etc. in the crude palm oil.

Get Price

3. Widely application. The palm oil refining machine can refine soybean oil, peanut oil, sunflower oil, mustards oil,cottonseed oil, sesame oil, palm oil, palm kernel oil and other crude vegetable oil. Palm oil refining process flow chart: Palm oil refining process flow chart. Crude palm oil refinery process

Get Price

Manufacturing Batch type palm kernel oil refinery plant,A batch type palm kernel oil refinery plant is the most widely used system to refine different oils. This batch type palm kernel oil refinery

Get Price

Palm Kernel Oil Production Line, Plam Kernel Oil Production Plant. For example, either single machine or production line are both for sale. Our palm kernel oil production line’s capacity is 10-100 tons per day and its residual oil rate is 5%, and we provide you with palm kernel oil

Get Price

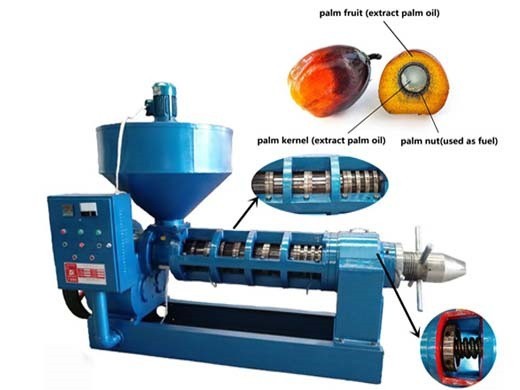

Palm oil is used widely for cooking due to its heat resistant property as compared to any other vegetable oil. The unique and best quality of Palm is that it produces two types of oil: Palm Oil and Palm Kernel oil. Palm oil is extract from the flesh of the Palm fruit and Palm Kernel Oil is extract from the seeds or kernel of the Palm

Get Price

In order to get the pure and refined oil, there are three main process in chemical palm oil refinery plant and chemical palm kernel oil refinery plant: degumming process, bleaching process and deodourising process.. According to the degree of automation, the refinery process can also be divided into Batch Refinery Plant, Semi-continuous Refinery Plant and Continuous Refinery

Get Price

Feel free to inquiry about cost of our palm oil refinery machines or detailed information about starting a small or large palm oil refinery plant! We are always at your services! Bleaching is one of the key processes of edible palm oil refinery. Palm oil bleaching is generally designed before deodorization in palm oil refinery.

Get Price

Turnkey Palm Oil Extraction Equipment. Process of Small Palm Oil Mill Plant. There is a wide range of techniques used for processing palm oil fruits into edible oil, cooking oil or bio-diesel oil. These techniques are categorized according to the complexity degree of the machinery being used in

Get Price

Palm Fruit ( Kernel) Oil Processing Machine/Palm Oil Extraction Machine. Capacity 5-100T/H. Oilseed Palm Fruit/ Kernel. Application palm fruit (FFB) and palm bunches. Description Henan huatai palm oil processing main processes: weighing, unloading fruit, sterilizer, removing fruits, mashed, pressing, shell and kernel separation, water treatment, palm oil refinery and fractionation,filling.

Get Price

High Quality Continuous Oil Refinery/palm Kernel Oil Refining Processing Machine Price For Sale,Find Complete Details about High Quality Continuous Oil Refinery/palm Kernel Oil Refining Processing Machine Price For Sale,Continuous Oil Refinery For Sale,Palm Kernel Oil Refining Processing Machine,Palm Kernel Oil Refining Processing Machine Price For Sale from Supplier or Manufacturer

Get Price

We offer 1,521 small scale palm oil refining machinery products. About 87% of these are oil pressers, 3% are machine oil purifier, and 1% are other farm machines. A wide variety of small scale palm oil refining machinery options are available to you,

Get Price

Chinese High-efficiency Palm Kernel/expeller Oil Processing Plant For Sale Palm Kernel Oil Refinery Plant Equipment Price,Find Complete Details about Chinese High-efficiency Palm Kernel/expeller Oil Processing Plant For Sale Palm Kernel Oil Refinery Plant Equipment Price,Palm Kernel Expeller Oil Processing Plant,Palm Kernel Oil Refinery Plant,Palm Oil Equipment from Oil Pressers Supplier or

Get Price

And we recommed continuous palm oil refinery process for 30tons and above capacity. But the processes in each palm oil refinery plant are almost the same. The complete palm oil refinery process includes degumming process, deacidification process, decolorization process, deodorization process

Get Price

Crude Palm Oil (CPO) is mainly further processed into edible oil for food purpose. To meet the international industry’s standards for edible oil, the crude palm oil produced by oil mills should be refined in palm oil refinery plant.Palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and palm oil deodorization.

Get Price

Crude Palm Kernel Oil Refinery Process Equipment Machine Transformer Linseed Cotton Oil Refining Plant,Find Complete Details about Crude Palm Kernel Oil Refinery Process Equipment Machine Transformer Linseed Cotton Oil Refining Plant,Palm Kernel Oil Refinery Equipment,Cotton Oil Refining Plant,Transformer Oil Refining Plant from Supplier or Manufacturer-Kinetic Energy Equipment

Get Price

Flow chart of the production chain of palm oil and palm kernel oil products for food application in the EU (1) Cultivation of palm fruits refining process. Studies have demonstrated that the presence of naturally refinery and commodity at stake throughout the refining process.

Get Price

Layout for Oil Palm Dry Fractionation Method . Crystallization Technique. The RBDPO Feed Oil is pumped to the Crystallizer. The fractionation system is batch type made up of vertical cylindrical vessel full of thermo-regulated water which is fitted with a

Get Price

If you want to build large scale palm kernel oil refinery plant, physical refining method is more suitable. The difference is the deacidification process. Large scale palm kernel oil refining machine has deodorization tower, in which the steam will take the free fatty acid and odors off totally.

Get Price

Manufacturing 2tpd palm kernel oil refinery plant,Palm kernel oil refining process is similar with palm oil refining process which also takes place in four stages.These stages of palm kernel oil refining process include degumming & deacidification process, bleaching process, and deodorization process,best 2tpd palm kernel oil refinery plant

Get Price

Palm Kernel Coconut Edible Oil Refinery Machinery for Sale, Find Details about Edible Oil Refinery, Oil Refinery Plant from Palm Kernel Coconut Edible Oil Refinery Machinery for Sale

Get Price

Palm Kernel Oil Production Line, Plam Kernel Oil For example, either single machine or production line are both for sale. Our palm kernel oil production line's capacity is 10-100 tons per day and its residual oil rate is 5%, and we provide you with palm kernel oil production and refining process design, manufacture, installation, commissioning and after-sales service if it is needed.

Get Price

We are a firm of engineers and business consultants. We fabricate and install palm kernel oil extracting factories both on small, medium and large scale for interested investors. We will also serve as consultants and mentors to young entrepreneurs who wish to invest in palm kernel oil

Get Price

Supply soybean oil,peanut oil,sunflower oil,palm oil,etc.edible oil. Sunflower oil refinery plant. Because of high wax content,sunflower oil dewaxing process should be added in sunflower oil refinery plant.So except for degumming,deacidification,decolorization...

Get Price

There are many steps needed before we get that golden palm oil you see at the supermarket. One of the main steps in this long process is palm oil refining. At Golden Agri-Resources’ (GAR) six palm oil refineries, several processes take place to purify the crude palm oil

Get Price

In degumming, the gum and fatty acid in crude palm oil and crude palm kernel oil are separated together with other impurities such as trace minerals, copper and iron by the application of phosphoric acid. In bleaching, the oil is mixed with bleaching earth (bentonite calcium) in a vacuum room to remove impurities and color pigments in the palm oil.

Get Price

Through the above steps, you will get high quality RBD palm kernel oil that can directly sale for more profit. Palm kernel oil refining process can show you how to refine crude palm kernel oil step by step. Hope this article can help you better understand how to set up palm kernel oil refinery plant, how to refine palm kernel oil.

Get Price

The company which involve in the oil palm industry should now and aware that there are problem to compute oil palm by product periodically. The product of oil palm is crude palm oil (CPO) as the main product, while palm kernel (PK) as its by product. CPO as the main product has bigger amount of production cost, and lower cost for PK.

Get Price