We offer 1,000 Palm Oil Plant Suppliers, and Palm Oil Plant Manufacturers, Distributors, Factories, Companies. There are 180 OEM, 178 ODM, 155 Self Patent. Find high quality Palm Oil Plant Suppliers on Alibaba.

Physical and Chemical Process in Palm Oil Refining Plant. Main processes in Chemical refining plant. Deodourising process: the palm oil and palm kernel oil are steamed at a temperature of 240°C to 260°C to get away the odors and tastes, and then they are cooled into room temperature (about 55°C) for further use.

Get Price

Crude oil pumped into the workshop, after flowmeter measurement through the oil filter, filter out the larger mechanical impurities in oil, then filtered oil into refining pot, add phosphate, remove the phosphorous impurity and rubber miscellaneous in the oil and add light lye, remove the little fatty acids make it produce soapstock, help ...

Get Price

How much it would cost to set up a palm oil processing mill in Nigeria? What is the best way to reduce the cost on palm oil processing machine purchase? Here, we can provide you all the palm oil processing machines at factory price to meet y

Get Price

Our palm oil refinery plant refines the crude red palm oil and transforms it into edible refined transparent oil. The series of refining processes are conducted in our palm oil refinery plant. At every stage of refining, the palm oil changes its state and improves its quality.

Get Price

We Can Offer Palm Oil Turnkey Project Service, Provide Palm Oil Processing Mill, Palm Kernel Expeller And Edible Oil Pressing Extraction Refining Machinery, A Professional And Best Palm Oil Mill Plant Manufacturer In China.

Get Price

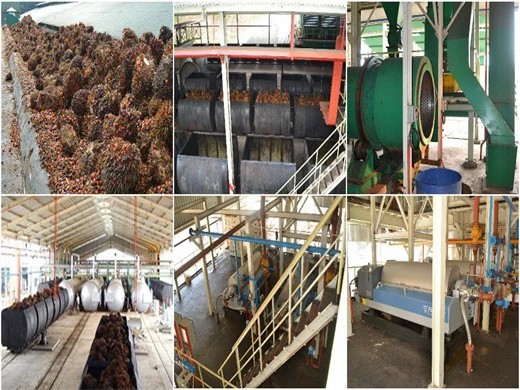

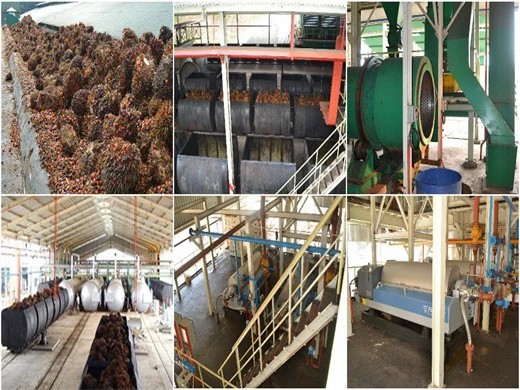

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines - biochemistry, chemical and mechanical engineering - and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a ...

Get Price

During talking with pHilippines customer, we learn that Philippine government encourage the palm oil plantationt and the philippines government plan to convert eight million hectares of idle and denuded lands into oil palm plantations. He told us this will be a good singal for people who want to set up a palm oil mill plant in Philippines ...

Get Price

Qie GROUP is a leader manufacturer of palm oil machine, here you can see palm oil refinery machine detials, palm oil extraction machine installation information,palm kernel oil refinery line, and project reports of crude palm oil refinery machine,palm oil mill plant etc.

Get Price

Fractionation Plant Assembly. Our palm oil fractionation technology and machinery is based on a fully continuous and automatic system without adding any solvent or chemical, ensuring premium quality of oil products.. The oil is cooled slowly to a certain degree in dissolved state, passing through plate filter to separate crystals and precipitate solid ester.

Get Price

Cost and Return of Oil Palm Plantation in the Philippines. The initial cost of start your oil palm plantation in the Philippines is mainly on planting materials. The fruit bunches of oil palm can be harvested after only 30 months after planting. Its productive life span can reach up to 30 years.

Get Price

Palm oil fractionation means to control cooling crystallization process to separate palm oil to 3 parts: palm stearin, palm olien and palm midfraction. The melting point of stearin is 50℃,and olein 24℃. Stearin is suitable to make margarine and cheese oil,

Get Price

Crude Palm Oil Processing Plant in Philippine. The Philippines is in a tropical climate and is well suited for the growing environment of palm trees, so the Philippines has a lot of palm orchard, so Joseph wants to build a palm oil mill in his country.

Get Price

Palm Oil Fractionation Plant Palm oil fractionation plant has three fractions: stearin (palm stearine),soft fat (palm olein) and middle section (palm mid-fraction) . After palm oil fractionation, palm oil will be clean after 5.5 hours in 0℃ to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.

Get Price

Crude oil pumped into the workshop, after flowmeter measurement through the oil filter, filter out the larger mechanical impurities in oil, then filtered oil into refining pot, add phosphate, remove the phosphorous impurity and rubber miscellaneous in the oil and add light lye, remove the little fatty acids make it produce soapstock, help

Get Price

Palm stearin is the solid fraction from the fractionation of palm oil. It can be used for obtaining palm mid fractions (PMF) and also in blends with other vegetable oils to obtain suitable functional products such as margarine fats, shortenings, vanaspati and others.

Get Price

Physical and Chemical Process in Palm Oil Refining Plant. Main processes in Chemical refining plant. Deodourising process: the palm oil and palm kernel oil are steamed at a temperature of 240°C to 260°C to get away the odors and tastes, and then they are cooled

Get Price

In the first step, Mr. Jose built the palm oil mill process first. After the hard working of our engineers and local workers, the crude palm oil processing plant is finished in 2012. Now the Philippine government encourage the palm oil plantation. We hope the market of palm oil in Philipine is better and better.

Get Price

Find here information of Palm Oil Plant selling companies for your buy requirements. Contact verified Palm Oil Plant Manufacturers, Palm Oil Plant suppliers, Palm Oil Plant exporters wholesalers, producers, retailers and traders in India.

Get Price

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

Get Price

qie palm oil production line in brazil of philippines,PRODUCT|Products information about palm oil extraction,We spliced in manufacturer of palm oil

Get Price

Supply BEST Palm Oil Processing Plant Oil palm is now the most important supplier of vegetable oil in the world. Machinery can offer you the BEST customized palm oil processing solutions for both fresh fruit bunch and palm kernel/nut.

Get Price

palm kernel mill in the philippines Palm Fruit ( Kernel) Oil Processing Machine/Palm Oil Henan huatai palm oil processing main processes: weighing, unloading fruit, sterilizer, removing fruits, mashed, pressing, shell and kernel separation, water treatment, palm oil refinery and fractionation,filling

Get Price

Manufacturing Palm oil fractionation plant,The palm oil fractionation process is designed to separate palm oil into two fractions, Palm Olein and Palm Stearine without the addition of any chemical or solvent.The palm oil fractionation technology is especially applicable for the palm oil fracti,best Palm oil fractionation plant

Get Price

Palm oil refinery process pdf. Refining is an essential process for a complete palm oil production line because there are still some impurities such as phospholipids, FFA, pigment, odor, etc. in the crude palm oil.

Get Price

PALM OIL PROCESSING. The extraction of palm oil from boiled palm fruit can be accomplished by handling successive batches of materials or continuously feeding material to the machines. 3.2.1 Batch systems. The batch systems work directly on successive loads of boiled fruit to extract oil in one operation for clarification.

Get Price

Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0℃ to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.

Get Price

Offer both turnkey solutions for both small and large Palm Oil Processing Projects. If you are planning for starting a palm oil mill plant, you must be interested to know about palm oil processing plant cost.How to make a successful palm fruit processing business plan?

Get Price

Palm oil fractionation is to separate palm oil into low melting point liquid phase (soft fat) and high melting point solid phase (stearin) by control the cooling and crystallizing process. Finally, the palm oil can be divided into 3 components: Palm Stearin (melting point around 50℃): Suitable for making margarine and shortening.

Get Price

A quiet traceable revolution in the palm oil industry. Golden Agri-Resources is the world’s second largest palm oil producer. Its managing director Agus Purnomo unravels the complexity of tracing palm oil supply chains and sheds light on how this will give birth to a more sustainable and resilient palm oil

Get Price

5 things about palm oil expansion in the Philippines. The Philippines has recently declared ambitions to become a major palm oil player; experts at the recently-held Responsible Business Forum on Food and Agriculture weigh in with some recommendations on how it should proceed.

Get Price

Palm Oil Fractionation Plant. Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0℃ to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and

Get Price

palm oil fractionation, soybean oil production machine, rice bran oil refining plant The top supplying countries or regions are United States, China, and Philippines, which supply 1%, 98%, and 1% of oil fractionation respectively. Oil fractionation products are most popular in

Get Price

Palm Oil Fractionation Plant Wholesale, Palm Oil Suppliers . There are 722 palm oil fractionation plant suppliers, mainly located in Asia. The top supplying countries or regions are China, India, and Indonesia, which supply 99%, 1%, and 1% of palm oil fractionation plant respectively.

Get Price

Palm oil mill process_Manufacture Palm oil extraction machine. 5. Palm oil mill process of oil clarifying: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment.

Get Price

Vegetable oil extraction machine manufacturer supplies high quality mature technology cooking oil processing machine and edible oil refinery plant with factory price,which can produce soybean oil, sunflower oil, groundnut oil, palm oil, etc.

Get Price

During talking with pHilippines customer, we learn that Philippine government encourage the palm oil plantationt and the philippines government plan to convert eight million hectares of idle and denuded lands into oil palm plantations. He told us this will be a good singal for people who want to set up a palm oil mill plant in Philippines.

Get Price

Planet is paying for palm oil profits. Palm oil production may have many benefits, but rapidly increasing plantation comes at a high cost to local and global environments. Palm oil makes a big contribution to modern life as one of the most-widely used substances in food, cooking, cosmetics, medicines and a range of chemicals.

Get Price