Thereby, the pyrolysis oil refining process distillaton plant becomes a very hot and highly profitable green project, which cost low, collect raw material easily and convert pyrolysis oil to diesel or gasoline efficiently (oil recovery rate is about 90%). Pyrolysis oil refining process distillation plant working process

We offer 1,365 waste tyre pyrolysis oil refining plant products. About 0% of these are Recycle Washing Line, 0% are Other Machinery & Industry Equipment. A wide variety of waste tyre pyrolysis oil refining plant options are available to you,

Get Price

Heating fuel of waste tyre pyrolysis plant can be wood, coal, fuel oil, nature gas and electricity. We manufacture and supply waste tyre & plastic pyrolysis plant for global market, Romiter waste tyre pyrolysis to oil plant has been exported to India, Pakistan,Thailand, Korea, South Africa, Mexico, Romania, Albania European countries and so on.

Get Price

We offer 2,892 refining pyrolysis oil products. About 26% of these are machine oil purifier, 1% are crude oil, and 1% are other industrial fuel. A wide variety of refining pyrolysis oil options are available to you, such as free samples.

Get Price

manufacture of Tire pyrolysis oil refining machine,Tyre to Diesel Plant,Tire pyrolysis oil refining machine uses the cracked oil obtained in the tire cracking equipment and is further purified to obtain clean and transparent diesel oil.Tire pyrolysis oil refining machineis mainly based on the working principle of high temperature distillation and condensation chemical reaction.

Get Price

Waste tyre pyrolysis plant. By using the waste tyre pyrolysis plant,we can get pyrolysis oil from waste tire. Secondly,with the help of one set of tire oil to diesel refining machine, the pyrolysis oil can be further refined into diesel oil or gasoline. Tire oil to diesel refining machine

Get Price

Or you want to further process the plastic and tyre pyrolysis oil? Kingtiger pyrolysis oil distillation plant for sale is a very hot and highly profitable green project, which costs low, collects raw material easily and convert pyrolysis oil to diesel or gasoline efficiently (oil recovery rate is about 90%).

Get Price

Our oil distillation plant is environmental friendly and energy saving, which make sure customer can use it anywhere. Nowadays, Romiter Group products include waste tyre pyrolysis to oil plant, waste plastic pyrolysis to oil plant, waste oil distillation machine, rubber crusher plant, carbon black recycling plant.

Get Price

Used oil/ pyrolysis oil distillation plant can convert used engine oil, waste oil, tyre oil, plastic oil into diesel and gasoline.

Get Price

Pyrolysis oil can be refined into valuable diesel oil through catalytic cracking and high temperature distillation technology. It is a method of separating mixtures based on differences in volatilitie Pyrolysis Tire oil and Plastic Oil Refining Plant.

Get Price

Pyrolysis Oil Distillation Plant. So far, our plants have been exported to more than 20 countries, such as India, Malaysia, South Africa, Canada, Peru, Jordan etc, and we have earned a good reputation from our customers. If you want to invest in the pyrolysis oil refining plant

Get Price

Or you want to further process the plastic and tyre pyrolysis oil? Kingtiger pyrolysis oil distillation plant for sale is a very hot and highly profitable green project, which costs low, collects raw material easily and convert pyrolysis oil to diesel or gasoline efficiently (oil

Get Price

Thereby, the pyrolysis oil refining process distillaton plant becomes a very hot and highly profitable green project, which cost low, collect raw material easily and convert pyrolysis oil to diesel or gasoline efficiently (oil recovery rate is about 90%). Pyrolysis oil refining process distillation plant

Get Price

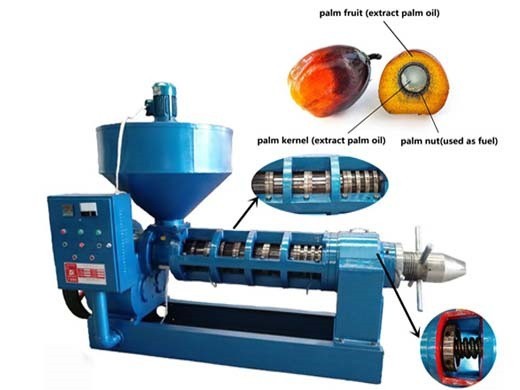

Waste tyre can be converted into oil and carbon black by a waste tyre pyrolysis plant.It mainly adopts the technology of pyrolysis of rubber tyres. It is a chemical reaction which can decompose macromolecule materials like plastic and tyres into micromolecule

Get Price

The MSW pyrolysis plant is a high-efficiency and high-quality waste to energy plants which is very popular in Malaysia now. It turns municipal solid waste (waste tyres, plastic, rubber wastes, oily sludge, etc) into fuel oil and carbon black through the process of pyrolysis.

Get Price

Supplier of recycling pyrolysis plant,tire recycling pyrolysis plant,pyrolysis plant, pyrolysis plants, plastic pyrolysis plant, Pyrolysis oil refining process distillation plant. Machine to recycle motor oil into diesel plant. Malaysian client ordered 2 sets 12T/D waste tyre recycling pyrolysis plant.

Get Price

have been specialized in Crude Oil Refinery manufacture for many years. Our main products are various kinds of Oil Recycling Machines,Pyrolysis Plant,Waste Tire Pyrolysis Plant,Waste Plastic Pyrolysis Plant,Waste Tire Recycling Also including Waste Oil Distillation Plant

Get Price

Working process and technology of continuous pyrolysis plant and oil refining machine recycling waste tyre/plastic to oil.

Get Price

The recycling of lubricating oil can not only prevent waste oil pollution, but also protect the environment. And it can also save man's limited petroleum resources at the same time. Used lube oil. As the latest recycling technology, DOING waste oil to diesel plant is specialized in refining used lube oil

Get Price

* Making diesel from tyres by waste tires oil refining equipment. After processed by the pyrolysis unit, the tyres are converted into fuel oil. To make the oil have wider applications and high value, we have developed the waste oil to diesel plant (also called pyrolysis oil to diesel machine, waste oil to diesel machine or waste oil

Get Price

Process Details of the Waste Tyre/Rubber To Fuel Oil Pyrolysis Plant. Pertreatment: You should treat the steel wire of the waste tyres before pyrolysis process. use the tyre crusher to process the waste tyres into small pieces, whose size should be under 50 mm. 1. Feed waste tyre/rubber into reactor by full-automatic feeding machine and make sure the door of feeding machine is closed.

Get Price

Beston crude oil refinery plant mainly consists of heating system, distillation system, dedusting system and electric control system, all of which play an important role in recycling waste oil materials or tyre/plastic pyrolysis oil. Crude Oil Refinery Plant Installed in Dominica Details about the oil refining

Get Price

Waste Used Oil Recycling Plant Process re refining lube . But as of now when technology has been upgraded to a new level, the use of the process has changed in a number of positions available for Waste Engine Lube Oil Recycling. The recycling or re-refining of waste oil and recycling of used engine oil creates some common confusion.

Get Price

Odifei Machinery manufacturing co. ltd founded in 2001 with the factory size of 10,000 Square Meter, 4 sub-companies and over 100 employees including managements, the sales and the engineers. Our continuous waste tire pyrolysis plant and continuous used oil refining plant are the real innovative development. It largely reduced downtime and increased the pyrolysis efficiency.

Get Price

4-12-2015· New Tech waste oil pyrolysis oil distillation plant,scrap tyre 250 liter per day waste motor oil pyrolysis plant Beston Continous Waste Oil Distillation/Refining Plant for Sale

Get Price

4-12-2015· New Tech waste oil pyrolysis oil distillation plant,scrap tyre 250 liter per day waste motor oil pyrolysis plant Beston Continous Waste Oil Distillation/Refining Plant for Sale

Get Price

By using the waste tyre pyrolysis plant,we can get pyrolysis oil from waste tire. Secondly,with the help of one set of tire oil to diesel refining machine, the pyrolysis oil can be further refined into diesel oil or gasoline. Tire oil to diesel refining machine. Tire oil to diesel refining machine can turn waste tyre oil to high quality diesel.

Get Price

Tyre oil refining process plant If we want to get diesel fuel ,you should buy two machine ,one maching named waste tyre pyrolysis plant ,the waste tyre pyrolysis plant can pyrolysis waste tyre to fuel oil and carbon black ,another machine is waste tyr

Get Price

Tyre pyrolysis plant is an environmental protection system which uses the continuous liquefaction technology and catalytic breakdown reaction to convert waste plastics into renewable resources, such as fuel oil, carbon black, steel wire, combustible gas and so on. The end products can be applied to diesel engines and generators directly, or come into high ranking diesel and gasoline through

Get Price

China Oil Sludge Refining Equipment Getting Fuel Oil and Diesel by Fully Continuous Pyrolysis Machine, Find details about China Oil Sludge Refining Equipment, Oil Sludge Refining from Oil Sludge Refining Equipment Getting Fuel Oil and Diesel by Fully Continuous Pyrolysis Machine .

Get Price

Leading Supplier of Waste Management Equipment, Plastic to Oil, Tire to Oil, Plastic to Fuel, Tyre Pyrolysis Plant, Pyrolysis Oil, Plastic to Diesel Equipment, Used Oil Refining

Get Price

The continuous waste tire to oil pyrolysis plant industry laid the status of? Lingfine?waste tire to oil plant, continuous waste tire to oil pyrolysis plant ?highly praised by customers at home and abroad, the continuous waste tire to oil pyrolysis plant solves the problem of waste recycling ,such as scrap tires, waste plastics, waste rubber ,thecontinuous waste tire to oil pyrolysis plant can

Get Price

Plastic pyrolysis oil is a kind of fuel oil obtained by cracking waste plastics in a plastic pyrolysis plant. The plastic pyrolysis oil to diesel distillation plant produced by DOING company by distillation technology can extract plastic pyrolysis oil into diesel oil, so that the plastic pyrolysis oil can achieve higher use value.

Get Price

Leading Supplier of Waste Management Equipment, Plastic to Oil, Tire to Oil, Plastic to Fuel, Tyre Pyrolysis Plant, Pyrolysis Oil, Plastic to Diesel Equipment, Used Oil Refining

Get Price

Fuel oil to diesel equipment. Pyrolysis technology plays an important role in reducing environmental pollution. Through the pyrolysis process, we can effectively convert used tires/plastics into a useful resource fuel oil, but in order to make fuel oil more widely used and of higher value, we can further process it by using waste oil recycling to diesel refining plant.

Get Price