Physical Refining of Soybean Oil. A prerequisite for physical refining of soybean oil was the development of degumming techniques that would lower P and other trace elements to a level that would allow reasonable dosages of silica and bleaching clay, bringing these components to a level equal to totally neutralized oil. All of these special ...

Oil Deodorization Section of the Oil Refining Plant. As the name suggests this process is meant for the removal of odor. Every vegetable oil has its own distinct natural odor. During neutralization and bleaching, unpleasant odors are imparted in the oil, thereby making it essential to remove this odor.

Get Price

Edible/vegetable oil refining is a step by step process. Refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. The entire oil refining plant process comprises degumming/neutralization, bleaching, deodorization, and winterization.

Get Price

Consequently, to reach the maximum oil quality all the steps of the refining process should be carried out with the minimum losses of desirable compounds. The major steps involved and the main components removed are shown in Table 1. As can be observed, alkali (or chemical) and physical refining are the standard processes used. The main ...

Get Price

Physical refining of edible oils has received renewed interest since the early 1970s when the process was reintroduced on a large scale to refine palm oil in Malaysia. Subsequent laboratory and field tests have also shown that physical refining can be used as a substitute for caustic or chemical refining, not only for high free fatty acid (FFA) oils such as palm, but also on low FFA oils such ...

Get Price

Henan Doing Company is a professional manufacturer of edible oil refinery machine, which is able to use chemical refining methord and physical refining methord. The process steps in edible oil refining can be adapted in accordance with the crude vegetable oil quality to give a good final oil quality with acceptable oil losses. Our engineer can ...

Get Price

Physical refining of edible oil is also called steam distillation deacidification, which is according to the characteristics of volatile difference between triglycerides and free fatty acids (under vacuum condition), in high vacuum (0.6 kPa) atmospheric pressure and high temperature (240 ~ 260 ℃) to remove free fatty acids and other volatile substances from oil by water vapor distillation.

Get Price

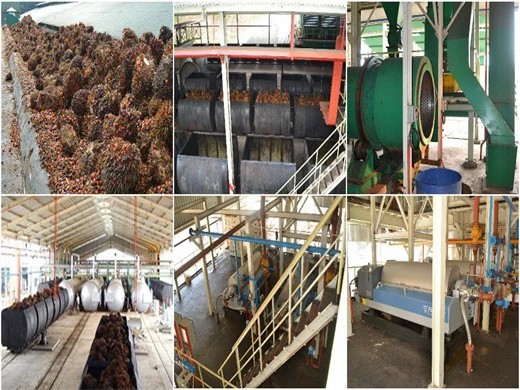

Palm oil should be obtained through a series of physical and chemical palm oil refining process in the mill plant to ensure the quality of refined palm oil. Only with suitable palm oil processing equipment, the whole physical and chemical pr

Get Price

The purpose of refining edible oils and fats is to remove free fatty acids and other objectionable substances including impurities while maintaining the nutritional value and ensuring the quality and stability of the end product. FEDIOL has developed a Code of Practice for refining vegetable oils (link), on which the description below is based.This process consistently yields safe products.

Get Price

Physical Refining of Soybean Oil. A prerequisite for physical refining of soybean oil was the development of degumming techniques that would lower P and other trace elements to a level that would allow reasonable dosages of silica and bleaching clay, bringing these components to a level equal to totally neutralized oil. All of these special

Get Price

2017-08-20· Physical and Chemical Refining: Oils may be refined by a series of processes that can be grouped together as `chemical refining' or `physical refining'. The former involves degumming, chemical neutralization, bleaching and deodorization, while the...

Get Price

Oil Deodorization Section of the Oil Refining Plant. As the name suggests this process is meant for the removal of odor. Every vegetable oil has its own distinct natural odor. During neutralization and bleaching, unpleasant odors are imparted in the oil, thereby making it essential to remove this odor.

Get Price

1984-07-01· Physical refining of edible oils has received renewed interest since the early 1970s when the process was reintroduced on a large scale to refine palm oil in Malaysia. Subsequent laboratory and field tests have also shown that physical refining can be used as a substitute for caustic or chemical refining, not only for high free fatty acid (FFA) oils such as palm, but also on low FFA oils such

Get Price

We use cookies to offer you a better experience, personalize content, tailor advertising, provide social media features, and better understand the use of our services.

Get Price

Edible/vegetable oil refining is a step by step process. Refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. The entire oil refining plant process comprises degumming/neutralization, bleaching, deodorization, and winterization.

Get Price

The main objective of refining is to remove the contaminants that adversely affect the quality of oil, thereby reducing the shelf life and consumer acceptance. However, this refining process needs

Get Price

2014-07-09· Quality of sunflower oil. The physico-chemical parameters of crude sunflower oil, refined oil obtained from the experimental unit and commercial refined oil sample is given in Table 1.The oil samples were found to be completely moisture free after refining and less than the maximum limit of

Get Price

2025-01-10· What is Vegetable Oil Refinery Machine? Vegetable oil refinery machine is professional equipment used to get rid of the impurities contained in the crude vegetable oils. Vegetable oil refinery machine is designed to produce high quality and standa...

Get Price

After the impurities contained in the crude oil according to the nature and purpose of refining oil and taking into account technical and economic indicators, using different methods and processes. Today we want to introduce is the physical and chemical methods. Edible oil refining machine

Get Price

Good Quality Vegetable Oil Refining Production Line And Dewaxing Equipment,Find Complete Details about Good Quality Vegetable Oil Refining Production Line And Dewaxing Equipment,Vegetable Oil Refining,Vegetable Oil Refining Production Line,Vegetable Oil Refining And Dewaxing Equipment from Oil Pressers Supplier or Manufacturer-.

Get Price

Vegetable Oil Refinery Plants very essentially convert the crude oils into high quality oil products that are fit for humans and also the oil modification processes that ensure that the physical properties of the fats and oils meet market requirements at minimal cost. This purpose is fulfilled in our Vegetable Oil Refinery Plant. It gives color

Get Price

Vegetable oil refining is necessary for vegetable oils & fats so they can be used for cooking and frying foods. Usually there are two ways of refining vegetable oil, they are Physical Refining & Chemical Refining. Physical refining means removal of gum in oil during process of degumming in special method and removing FFA in process of

Get Price

Physical Refining In Physical Refining, Vegetable Oil is subject to distillation to remove free fatty acids. The alkali treatment is completely avoided. This reduces the amount of waste water and eliminates production of soap. This process is becoming more popular.

Get Price

Crude Oil Refinery for Sale, Crude Oil Refinery, Oil Refinery manufacturer / supplier in China, offering Vegetable Oil Refining Equipment Cottonseed Crude Oil Refinery for Sale, Food Peanut Kernel Nut Grinder Grinding Machine, 800-1000 Kg/H Passion Fruit Juicer Without Seeds and Shell and so on.

Get Price

The brief introduction of oil refinery plant . Edible oil refining includes a series processing procedures as degumming, neutralization, bleaching, deodorization and winterisation. In general there are two methods of vegetable/edible oil processing, one is physical refining and the other is chemical refining.

Get Price

Two processes have been developed for the refining of edible oils and fats, i.e. physical and chemical refining; the decision which process to use depends on the types and qualities of the crude oil to be processed (Figure 1).The names physical and chemical refining come from the process technology used to remove the Free Fatty Acids (FFA) that are responsible for the oil acidity.

Get Price

2003-03-26· It relies on distillation to remove acids. Europeans have no choice in finding an alternative to sodium hydroxide, and they are applying physical refining. But physical refining is more costly, and it requires very high temperatures that no oils can tolerate without nutritional degradation. Vitamin E is removed with physical refining.

Get Price

The purpose of refining edible oils and fats is to remove free fatty acids and other objectionable substances including impurities while maintaining the nutritional value and ensuring the quality and stability of the end product. FEDIOL has developed a Code of Practice for refining vegetable oils (link), on which the description below is based.This process consistently yields safe products.

Get Price

2015-12-26· Research shows that to obtain good quality and stable oil after refining, the phosphorous content of the crude oil should not exceed 20 ppm, and the phosphorous content of the pre-treated oil immediately prior to physical refining should not exceed 5 ppm. The reduction to these levels brings very low levels of trace metals such as copper and iron.

Get Price

Refining methods for palm oil refinery plant : There are two refining methods for the vegetable oil refining in the edible oil refinery plant. They are physical refining and chemical refining. Physical refining means removing gum in oil during process of degumming in special method and removing FFA in process of deodorizing by steam. Chemical

Get Price

.Study of refining wastewater pollution: case of vegetable oil refining industry Morocco M. Chatoui *¹, S. Lahsaini 1, S. Souabi ¹, M. A. Bahlaoui ¹, S. Hobaizi ¹, A. Pala² ¹ Laboratory of Water Engineering and Environment, Faculty of Sciences and Technologies, Hassan II Casablanca University, BP 146, Mohammedia, Morocco,

Get Price

Edible or vegetable oil efining process can remove phospholipids, FFA, pigment, off-flavor and other impurities. We supply quality and professional edible / vegetable oil refining equipment and technology to ensure that best finished oil is achieved with the lowest production cost.

Get Price

edible oil refinery With a growing world population, the demand for edible oil is also increasing year after year. Since most crude vegetable oils obtained either from expellers or solvent extraction plant contains impurities and need to be (at partially) refined for edible or technical applications, increased production volumes have resulted in a serious expansion of the edible oil refinery

Get Price

Alkali Refining: Plant Design Crude oil dosation The capacity of the plant is adjusted by a speed controlled crude oil pump in combination with a massflowmeter. A pre-strainer is installed to protect the pump and following equipment . The oil temperature is adjusted with a heat exchanger by means of steam. Dual pre-strainer Massflow meter Crude

Get Price

both chemical and physical refining process (the investment for an universal plant is only slightly higher than the cost of a standard chemical or physical refining line). 1 Multipurpose refining plant (Turkey) Capacity: 300 t/d 2 2 Continuous deodorizing plant 1 Applicability Final quality and keepability Oil yield

Get Price

Our proprietary method of physically refining vegetable and animal oils, including emu oil, uses a carefully balanced mixture of temperature, pressure, time, and natural clays in order to maximize finished oil quality and yield.. We have discovered this process through exhaustive research and lab testing and finely tuned it to ensure the highest quality oils in the industry.

Get Price

This physical refining process is becoming more popular. Chemical Refining . In Chemical Refining, Vegetable Oil is treated with caustic lye for separation of free fatty acids from oil. This is a conventional process that can be applied to all oils. A byproduct of alkali refining is soapstock, which is used for manufacture of low quality

Get Price